In the intricate world of paper production, every component plays a vital role in achieving the desired quality and efficiency. Yet, few elements are as critical and as relentlessly challenged as the rolls that guide, press, and dry the paper web. These unsung heroes endure immense pressure, fluctuating temperatures, harsh chemicals, and constant abrasion, all while maintaining precise dimensions and flawless surfaces. The performance and longevity of these rolls directly impact machine speed, paper quality, energy consumption, and ultimately, the mill's profitability. This is precisely why the choice of your paper machine roll manufacturer isn't merely a procurement decision; it's a strategic partnership that can define the success of your operations. But with numerous options available, how do you identify the manufacturer that truly understands your unique needs and can deliver the reliability you depend on?

The Unseen Heartbeat of Papermaking: Understanding Paper Machine Rolls

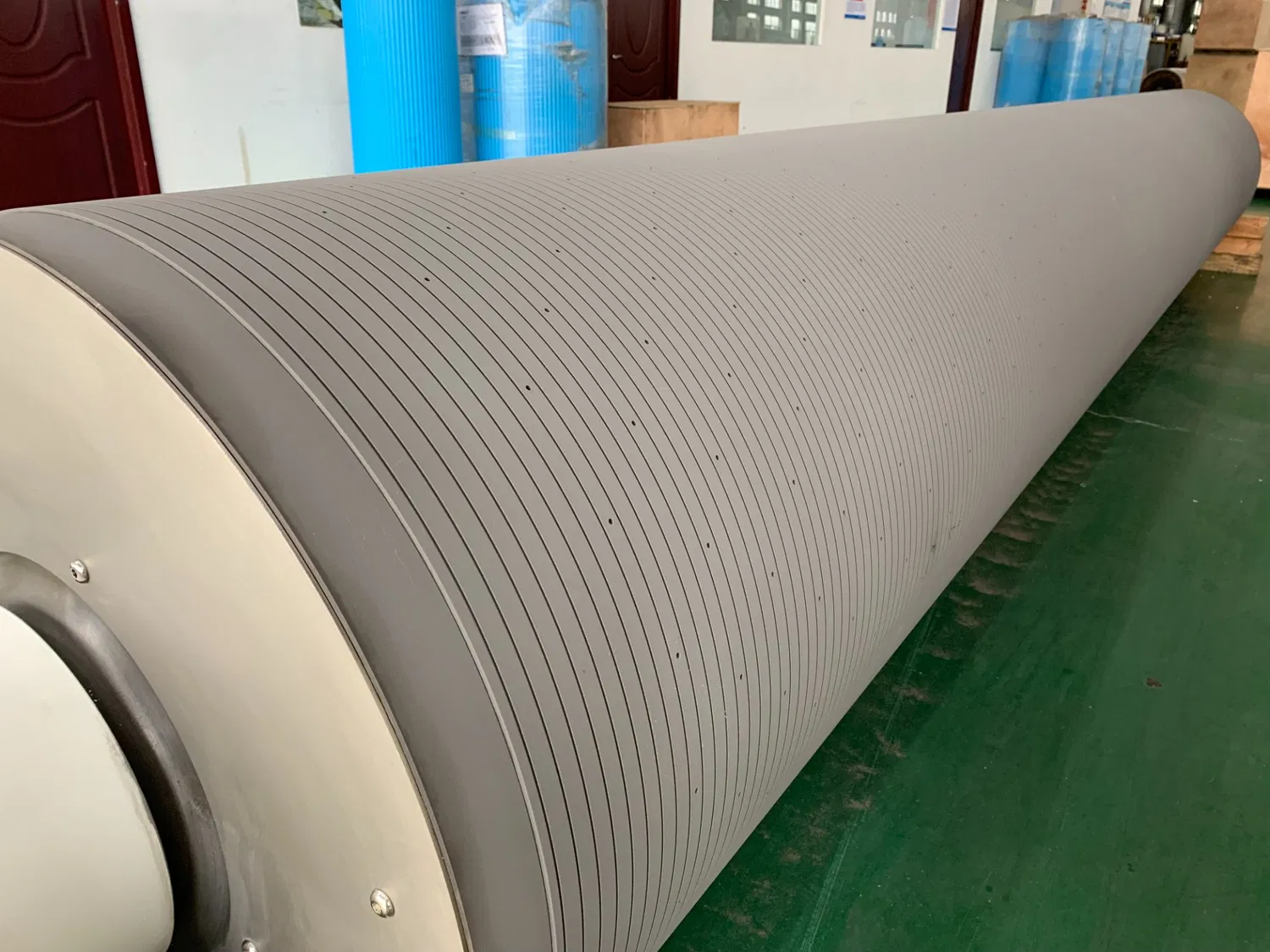

Think of a paper machine as a symphony of moving parts, and the rolls are its complex, dynamic core rhythm. Each roll type serves a specific purpose within the different sections of the machine – from the forming section where the pulp slurry begins to dewater, through the press section that mechanically removes more water, into the dryer section where heat completes the process, and finally, through the calender section for surface finishing. Breast rolls, wire rolls, felt rolls, press rolls (including suction, plain, grooved, blind-drilled), dryer rolls, and calender rolls – the list goes on. Each has unique material requirements, surface characteristics, internal designs (for heating, cooling, or vacuum), and tolerance specifications that must be met with absolute precision. A single deviation in concentricity, balance, or surface finish on just one roll can disrupt the entire process, leading to web breaks, uneven moisture profiles, poor paper quality, and significant downtime. It's a demanding environment where only expertly engineered and manufactured rolls can survive and perform consistently.

Interestingly enough, the operational life of these rolls is anything but simple. They are subjected to continuous stress cycles, abrasive contact with the paper web, felts, and wires, and corrosive environments depending on the process chemicals used. High temperatures in the dryer section put materials under immense thermal load, while high-nip loads in the press section demand exceptional mechanical strength and deformation resistance. Vibration, especially at high speeds, can quickly lead to bearing failures and quality issues, requiring meticulous balancing. The sheer variety of papers produced, from tissue to board, further complicates matters, as each requires specific roll configurations and surface properties. Frankly speaking, producing a reliable paper machine roll is a feat of materials science, mechanical engineering, and manufacturing excellence honed over years. Understanding these challenges is the first step in appreciating the value a truly experienced paper machine roll manufacturer brings to the table.

Choosing Your Partner: What Defines a Leading Paper Machine Roll Manufacturer?

Selecting the right manufacturer goes far beyond comparing price lists. It requires a deep dive into their capabilities, experience, and commitment to quality. A leading paper machine roll manufacturer distinguishes itself through several key attributes. Firstly, their engineering prowess is paramount. Do they possess the technical expertise to understand your specific machine configuration, paper grades, and operational challenges? Can they recommend or design rolls optimized for your unique conditions, considering factors like speed, load, temperature, and chemical exposure? Experience in working with a wide range of paper machines and mill types is invaluable, as it provides them with a broad knowledge base to draw upon. Look for a manufacturer with a proven track record, one that has successfully tackled complex problems and delivered reliable solutions in demanding environments similar to yours.

Precision engineering and design innovation are non-negotiable. The demands on paper machine rolls are constantly increasing with faster machine speeds and stricter quality requirements. A top manufacturer invests in research and development to explore new materials, advanced coatings, and improved internal designs (like optimal baffling for dryer rolls or sophisticated crown control mechanisms for press rolls). When you need custom paper machine rolls designed for a specific upgrade or a challenging application, their ability to provide tailored engineering solutions is critical. This isn't just about replicating an existing design; it's about optimizing performance for your specific mill's constraints and goals. They should be able to provide detailed engineering drawings, performance simulations, and clear technical justifications for their recommendations, demonstrating a thorough understanding of the underlying physics and mechanics.

Manufacturing capabilities and rigorous quality control processes form the backbone of their operation. Possessing state-of-the-art machining equipment, including large-capacity lathes, grinders, and balancing machines, is essential for achieving the tight tolerances required for paper machine rolls. Welding procedures must be robust and reliable, especially for critical components like journals and shells. Heat treatment and surface finishing processes must be precisely controlled to ensure material integrity and the desired surface properties. Crucially, a leading manufacturer implements stringent quality checks at every stage, from raw material inspection to final dimension verification and dynamic balancing. They should be able to provide comprehensive quality documentation and testing reports. In my experience, witnessing a manufacturer's commitment to quality firsthand during a facility visit can be incredibly insightful; it reveals their true operational standards and attention to detail.

Beyond Manufacturing: Services Offered by a Comprehensive Partner

The relationship with a paper machine roll manufacturer shouldn't end once the new roll is shipped. A truly comprehensive partner offers services that support the entire lifecycle of your rolls. Paper mill roll repair services are a prime example. Rolls inevitably experience wear, damage, or changes in surface characteristics over time. Expert repair and refurbishment, including regrinding, resurfacing, bearing journal repair, and crack welding, can significantly extend the life of a roll at a fraction of the cost of replacement. A manufacturer with strong repair capabilities understands the original design specifications and metallurgy, ensuring that refurbishments restore the roll to its optimal performance state. They should also offer comprehensive inspection services to assess the condition of existing rolls and recommend appropriate maintenance or repair actions, helping you proactively manage your roll inventory and maintenance schedule.

Surface coatings and treatments are another critical area where a manufacturer's expertise can make a significant difference. The right coating can enhance wear resistance, improve release properties (preventing paper sticking), protect against corrosion, or provide a specific surface texture required for a particular paper grade. Options range from thermal spray coatings like ceramics and carbides to rubber covers and composite materials, each offering unique advantages. A knowledgeable manufacturer will work with you to select the coating best suited for the specific roll position and operating conditions, considering factors like temperature, pH, abrasive particles, and nip pressure. Applying these coatings requires specialized equipment and expertise to ensure proper adhesion, thickness, and uniformity, all of which are critical for long-term performance and preventing premature failure.

Furthermore, a forward-thinking manufacturer can assist with technological advancements and upgrades. Paper machine technology is constantly evolving, and older machines can often be significantly improved by incorporating modern roll designs, materials, or control systems. Perhaps you need high-performance paper machine rolls designed for faster speeds, higher loads, or improved energy efficiency. A manufacturer with strong engineering and R&D capabilities can help you evaluate the potential benefits of such upgrades, design compatible rolls, and even provide installation support. This partnership approach to technological improvement can unlock hidden potential in your existing machinery, allowing you to compete more effectively by improving productivity and reducing operating costs without investing in an entirely new machine line. It's about leveraging their expertise to drive innovation within your own mill.

The Impact of Quality Rolls on Your Bottom Line

The performance of your paper machine rolls has a direct and substantial impact on your mill's profitability. High-quality, precisely manufactured rolls contribute to smoother machine operation, significantly reducing the frequency and duration of costly web breaks and unplanned downtime. Optimized roll surfaces and designs ensure consistent moisture profiles and uniform paper properties, leading to higher quality paper that meets stringent customer specifications and reduces reject rates. Rolls designed for energy efficiency, such as lightweight dryer rolls or optimized press rolls, can lower power consumption. Additionally, durable rolls and effective repair services reduce the frequency of replacements and maintenance interventions, lowering overall maintenance costs. It's a ripple effect: reliable rolls mean a reliable machine, which translates directly into higher throughput, lower operating expenses, and improved profitability. Investing in rolls from a reputable paper machine roll manufacturer isn't an expense; it's an investment in the long-term health and efficiency of your operation.

Ultimately, the relationship with your paper machine roll manufacturer should be a partnership built on trust and mutual understanding. A good manufacturer acts as a technical resource, not just a supplier. They should be accessible, responsive, and willing to work collaboratively to solve problems and optimize performance. This might involve site visits to assess machine conditions, providing training for your maintenance staff, or offering technical support for troubleshooting roll-related issues. They should proactively communicate lead times, keep you informed about production progress, and stand behind the quality of their products and services. This level of engagement is what transforms a transactional relationship into a strategic alliance that supports your mill's continuous improvement efforts and helps you stay ahead in a competitive market. Have you ever considered the full value a dedicated partner could bring beyond just supplying parts?

Choosing the right partner among paper machine roll manufacturers is one of the most critical decisions you will make to ensure the consistent performance and longevity of your paper machine. Look for a manufacturer with deep engineering expertise, advanced manufacturing capabilities, a strong focus on quality control, and comprehensive service offerings, including expert repair and refurbishment. Consider their ability to provide custom solutions and support your mill's technological advancement. By partnering with a manufacturer that truly understands the challenges and nuances of papermaking, you are not just acquiring rolls; you are securing reliability, efficiency, and a partner dedicated to your success. Evaluate potential manufacturers based on their technical competence, proven track record, quality processes, and the breadth of their services. Take the time to visit their facilities and speak with their engineering team. Your mill's future performance depends on it.

For more detailed information, please visit our official website: paper machine roll manufacturer