The Importance of Paper-Making Rolls in Production

In the world of paper production, the rolls used in the process play a pivotal role. To be honest, without efficient and well-maintained rolls, achieving high-quality paper products is nearly impossible. But how can you ensure your paper-making rolls are up to par? Let's dive into the details.

Understanding Different Types of Paper-Making Rolls

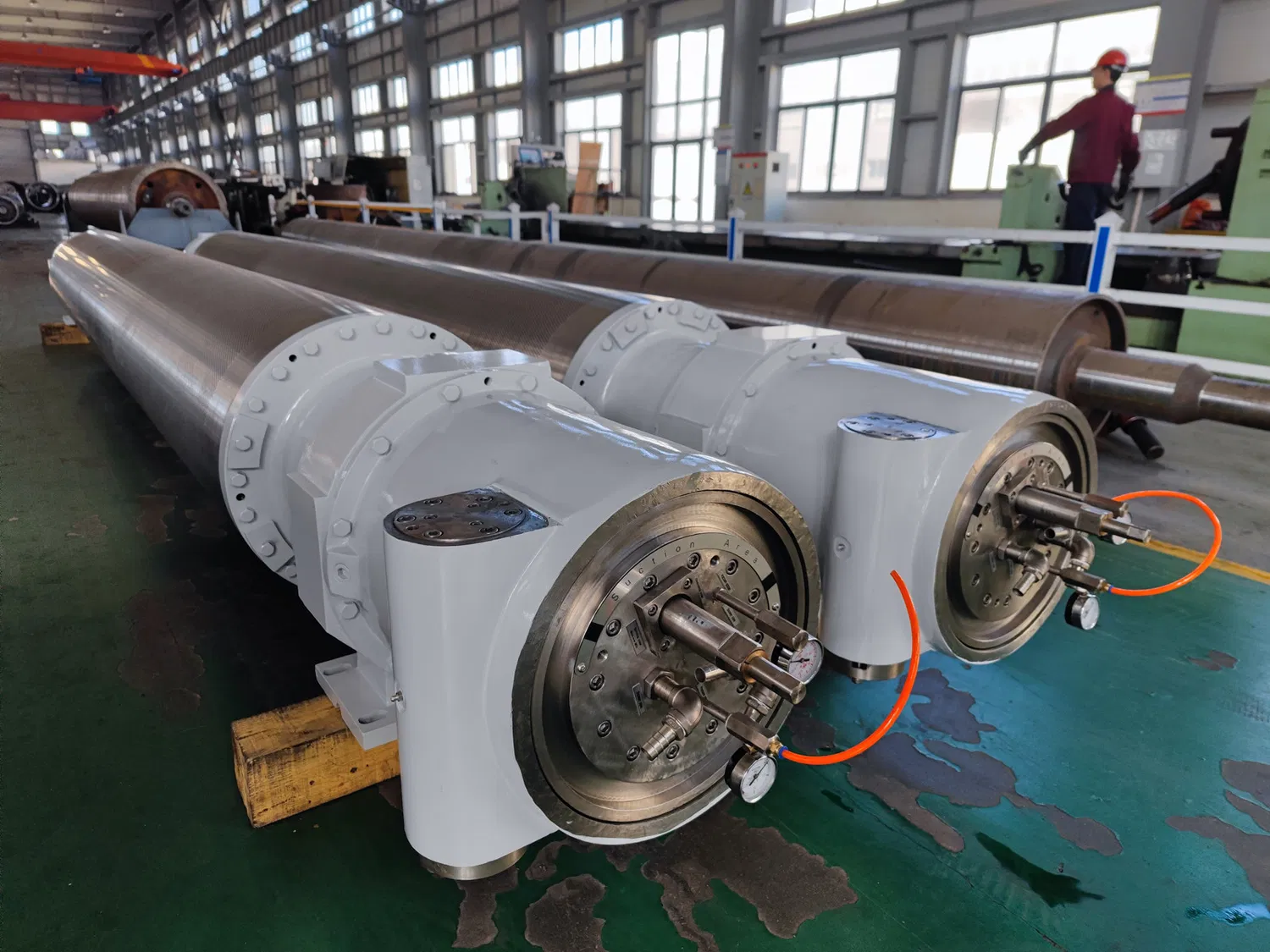

First and foremost, it's essential to familiarize yourself with the various types of paper-making rolls. Each roll serves a unique purpose, such as pressing, drying, or smoothing the paper. Commonly used rolls include press rolls, suction rolls, and calendar rolls. Understanding the function and importance of each roll type is vital in identifying areas for improvement.

Choosing the Right Materials for Your Rolls

When it comes to upgrading your paper-making rolls, selecting the appropriate materials can significantly impact output. Materials like chrome, ceramic, and rubber each have their advantages and disadvantages, depending on the specific application. For instance, chrome rolls excel in providing a smooth surface finish, while ceramic rolls offer superior heat resistance and durability.

The Benefits of Modern Materials

Interestingly enough, recent advancements in material technology have led to the development of rolls with enhanced performance and longevity. For example, many modern rolls now feature advanced coatings that improve wear resistance and reduce friction, ultimately leading to better output and energy savings.

Proper Maintenance and Inspection Techniques

Regardless of the materials used, proper maintenance is crucial in ensuring optimal performance from your paper-making rolls. Regular inspections can help identify potential issues before they escalate, preventing costly downtime and repairs. Some essential maintenance tasks include cleaning, lubrication, and grinding or recovering the roll surface.

The Role of Predictive Maintenance

Frankly speaking, predictive maintenance is a game-changer in the paper-making industry. By monitoring roll performance continuously, you can predict and address potential issues proactively. This approach not only extends the lifespan of the rolls but also ensures consistent output and minimizes production disruptions.

Upgrading Your Rolls: Practical Tips and Considerations

Now that we've covered the basics let's explore some practical tips for upgrading your paper-making rolls:

- Consult with roll manufacturers or experts to discuss the best material options for your specific application.

- Implement a comprehensive maintenance program, including regular inspections, cleaning, and lubrication.

- Invest in predictive maintenance tools and technologies to monitor roll performance continuously.

In Conclusion

Upgrading your paper-making rolls can significantly improve output and operational efficiency. By understanding the different roll types, selecting the appropriate materials, and maintaining your rolls properly, you can ensure your paper mill stays competitive in today's market. If you're curious about how our company can help you upgrade your paper-making rolls, don't hesitate to reach out.

For more detailed information, please visit our official website: paper-making rolls