In today's fast-paced business environment, efficiency and cost-effectiveness are paramount. Businesses across various sectors are constantly seeking innovative solutions to streamline their operations, reduce waste, and enhance productivity. One such solution that has gained significant traction is the paper banding machine. But what exactly is a paper banding machine, and why should your business consider investing in one? This comprehensive guide will delve into the world of paper banding machines, exploring their benefits, applications, and how they can revolutionize your packaging and bundling processes. Have you ever considered how much time and resources are spent on manual bundling and packaging? Let's explore how this technology can offer a smarter, more sustainable alternative.

Understanding Paper Banding Technology

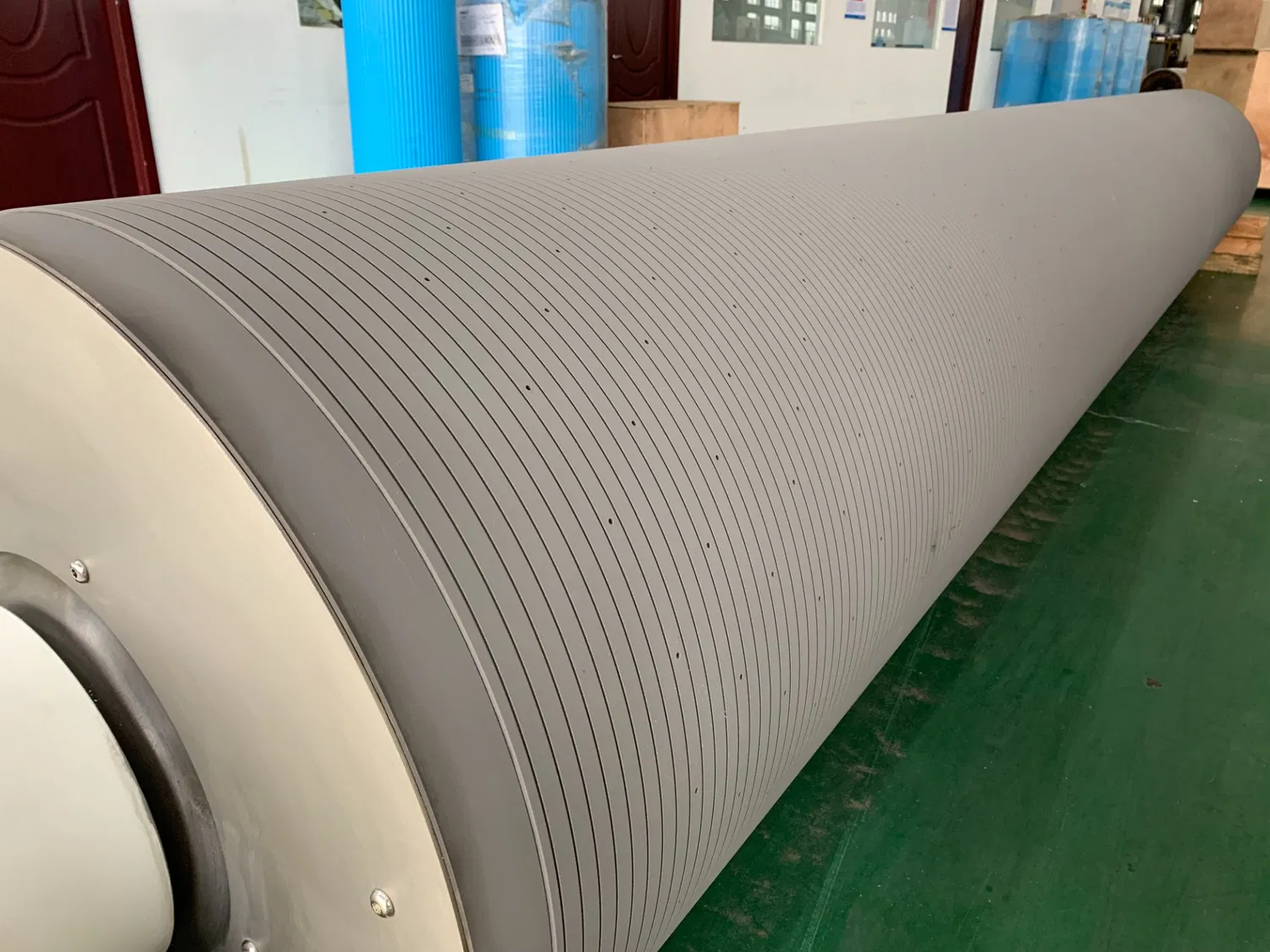

At its core, a paper banding machine is a device designed to securely bundle and wrap products using paper tape or banding material. Unlike traditional plastic strapping or shrink wrap, paper banding offers a more eco-friendly and often more aesthetically pleasing alternative. These machines utilize tension and heat or adhesive to create a tight and secure band around a stack of items, a single product, or even delicate materials. The technology behind paper banding is surprisingly versatile, ranging from simple manual devices to fully automated, high-speed systems capable of handling thousands of bundles per hour. The choice between different types often depends on the volume of products being processed and the specific application. From small offices to large industrial facilities, there's a paper banding solution tailored to meet diverse needs and scales of operation. It’s worth noting that the advancements in paper banding technology have made it increasingly reliable and efficient, challenging older, less sustainable methods.

The Key Advantages of Using Paper Banding Machines

Why are businesses increasingly turning to paper banding machines? The answer lies in the multitude of benefits they offer. Firstly, and perhaps most importantly in today's environmentally conscious world, paper banding is a significantly more sustainable option compared to plastic alternatives. Paper is biodegradable, recyclable, and often made from renewable resources, reducing your environmental footprint and appealing to eco-conscious consumers. Secondly, paper banding can be incredibly cost-effective in the long run. While the initial investment in a machine may seem significant, the reduced material costs compared to plastic strapping, along with increased efficiency and reduced labor costs, can lead to substantial savings over time. Furthermore, paper banding offers a clean and professional look to bundled products, enhancing brand image and presentation. This is particularly important for consumer-facing products where visual appeal plays a crucial role in purchasing decisions. In my experience, businesses that switch to paper banding often see a positive impact on both their bottom line and their brand perception.

Enhanced Efficiency and Productivity

One of the most compelling advantages of implementing paper banding machines is the significant boost in efficiency and productivity they provide. Manual bundling and strapping are time-consuming and labor-intensive processes, prone to inconsistencies and human error. Automated or even semi-automatic paper banding machines drastically reduce the time required to bundle products, allowing for faster throughput and increased production capacity. These machines can operate at speeds that are simply unattainable with manual methods, freeing up valuable employee time for more strategic tasks. Moreover, the consistency of machine banding ensures uniform bundles, reducing product damage during handling and transportation. For businesses dealing with large volumes of products, this increase in speed and consistency translates directly into higher output and improved overall operational efficiency. It’s frankly amazing how much time and effort can be saved simply by automating this crucial step in the packaging process.

Cost Savings and Reduced Material Waste

Beyond efficiency gains, paper banding machines contribute significantly to cost savings and waste reduction. As mentioned earlier, paper banding material is generally less expensive than plastic strapping and shrink wrap, leading to direct material cost reductions. Furthermore, the precise application of banding material by machines minimizes waste compared to manual methods where excess material is often used. The durability of paper bands, when properly applied, also reduces the risk of bundle breakage during transit, minimizing product damage and associated losses. Consider the cumulative effect of these savings over time – for high-volume operations, the financial benefits can be substantial. Moreover, the move towards sustainable packaging materials can also lead to positive public relations and potentially open doors to environmentally conscious markets. From a purely economic standpoint, investing in paper banding is often a very sound decision.

Applications Across Diverse Industries

The versatility of paper banding machines is evident in their wide range of applications across various industries. In the printing and graphics industry, they are ideal for bundling brochures, leaflets, business cards, and other printed materials, ensuring neat and secure packaging for distribution. The packaging industry itself benefits greatly, using paper banding for bundling boxes, cartons, and various retail products. Food and beverage companies utilize paper banding for multipackaging items like canned goods, bottled drinks, and packaged foods, often opting for printed bands for branding and promotional purposes. Even the pharmaceutical industry finds paper banding useful for securing boxes of medication and medical supplies, where tamper-evidence and secure packaging are critical. From e-commerce fulfillment centers to manufacturing plants, the applications of paper banding are incredibly diverse, highlighting its adaptability to different product types and operational needs. Have you ever noticed paper bands on products you’ve purchased? They’re likely more common than you realize.

Ideal for the Printing and Graphics Sector

For the printing and graphics industry, paper banding machines are particularly well-suited. Printed materials, such as brochures, magazines, and newspapers, require neat and secure bundling for distribution and storage. Paper banding provides a clean and professional finish that complements the high-quality nature of printed products. It prevents damage during handling and transportation, ensuring that printed items arrive in pristine condition. The ability to use printed paper bands also offers an additional branding opportunity, allowing print shops and publishers to reinforce their brand identity and add promotional messages directly to the packaging. Compared to plastic wrapping, paper banding is also easier to remove and recycle, aligning with the sustainability goals often prioritized in the printing sector. It’s a practical and environmentally conscious choice for any business dealing with printed materials.

Packaging and Retail Solutions

In the broader packaging and retail landscape, paper banding machines offer versatile solutions for a wide array of products. From bundling multiple retail units for sale to securing boxes and cartons for shipping, paper banding provides a robust and reliable method. It is particularly effective for products that require gentle handling, as the paper band can be applied with adjustable tension to prevent crushing or damage. The aesthetic appeal of paper banding is also a significant advantage in retail settings, presenting products in a clean and organized manner that enhances shelf appeal. Furthermore, the option to use pre-printed paper bands allows retailers to incorporate branding, product information, or promotional messaging directly into the packaging, creating a cohesive and impactful presentation. For businesses looking to improve both the functionality and the visual appeal of their packaging, paper banding is a compelling option.

Choosing the Right Paper Banding Machine for Your Needs

Selecting the appropriate paper banding machine for your business requires careful consideration of several factors. Firstly, assess your production volume. For low-volume operations, a manual or semi-automatic machine might suffice, while high-volume environments will benefit from fully automated systems. Secondly, consider the size and type of products you need to band. Different machines are designed to handle various product dimensions and shapes. Thirdly, think about the level of automation you require. Do you need a machine that automatically feeds and bands products, or is a simpler, hand-fed model adequate? Finally, factor in your budget and the long-term return on investment. While a more expensive machine might offer greater efficiency, ensure it aligns with your financial capabilities and projected savings. Our company offers a range of paper banding solutions to meet diverse needs, and our experts can help you assess your requirements and choose the ideal machine for your specific application. It's all about finding the right balance between functionality, efficiency, and cost-effectiveness.

Manual, Semi-Automatic, and Automatic Options

Paper banding machines come in various levels of automation to cater to different operational scales and budgets. Manual machines are the simplest and most cost-effective, ideal for low-volume applications. They require manual feeding and operation, making them suitable for small businesses or occasional use. Semi-automatic machines automate certain aspects of the banding process, such as tensioning and sealing, while still requiring manual product feeding. These offer a step up in efficiency for medium-volume operations. Automatic paper banding systems represent the highest level of automation, handling product feeding, banding, and ejection automatically. These are designed for high-speed, continuous operation in large-scale production environments. The choice between manual, semi-automatic, and automatic depends heavily on your production volume, labor costs, and desired level of efficiency. Understanding these distinctions is crucial for making an informed investment decision. Thinking about your current and future production needs is a good starting point.

Embracing Sustainable Packaging Solutions

In an era of increasing environmental awareness, embracing sustainable packaging solutions is no longer just a trend but a necessity. Paper banding machines perfectly align with this shift towards sustainability, offering an eco-friendly alternative to traditional plastic-based packaging methods. By choosing paper banding, businesses can reduce their reliance on non-biodegradable materials, minimize plastic waste, and enhance their environmental profile. This commitment to sustainability resonates with environmentally conscious consumers and can provide a competitive advantage in the marketplace. Furthermore, many regions are implementing stricter regulations on plastic packaging, making paper-based alternatives increasingly attractive from a compliance perspective. The move towards paper banding is not just about environmental responsibility; it’s also about future-proofing your business and aligning with evolving consumer preferences and regulatory landscapes. Frankly speaking, sustainability is becoming a core business value, not just an add-on.

In conclusion, paper banding machines offer a compelling combination of efficiency, cost-effectiveness, and sustainability. From streamlining packaging processes to reducing material waste and enhancing brand image, the benefits are undeniable. Whether you operate in the printing, packaging, food, pharmaceutical, or any other industry requiring product bundling, paper banding solutions can significantly improve your operations and contribute to a more sustainable future. By carefully assessing your needs and choosing the right type of machine, you can unlock the full potential of this innovative technology and gain a competitive edge in today's market. Ready to explore how paper banding can transform your business? Contact us today to learn more about our range of paper banding solutions and how we can help you find the perfect fit for your needs.

For more detailed information, please visit our official website: paper banding machine