In the realm of paper manufacturing, particularly when it comes to specialty coated papers, the importance of precision cannot be overstated. These papers, designed for applications ranging from high-end printing and packaging to technical and industrial uses, demand an impeccable surface finish and consistent properties. At the heart of their production lies the paper machine, and within this complex machinery, the rolls play a pivotal role. Among these, precision-ground paper machine rolls are absolutely critical for achieving the desired quality and performance of specialty coated papers. These rolls are not merely components; they are engineered instruments that directly influence the coating process, impacting everything from coating uniformity and thickness to the final paper's smoothness and printability. Understanding their significance is the first step in appreciating the intricate science behind crafting exceptional specialty coated papers.

The Unseen Foundation: Precision in Coating Rollers

To truly grasp the necessity of precision-ground rolls, it's essential to consider the delicate nature of the coating process itself. Specialty coated papers receive their unique characteristics through the application of various coatings – pigments, binders, and additives – onto the base paper. This coating process requires an incredibly even and controlled application to ensure consistent paper properties across the entire web. Any imperfection in the paper machine rolls, particularly the coating rollers, will be directly translated into defects in the coated paper. Imagine a slightly uneven roll surface; this seemingly minor flaw can lead to variations in coating thickness, streaks, or even uncoated areas on the paper. For high-value specialty papers, these defects are unacceptable. Precision-ground rolls, manufactured to tolerances measured in microns, eliminate these potential flaws, providing a perfectly uniform surface for coating application. This level of precision is not just desirable; it's a fundamental requirement for producing specialty coated papers that meet stringent quality standards.

Material Matters: Selecting the Right Roll Composition

The precision grinding process is only one part of the equation. The material from which the paper machine rolls are made is equally crucial, particularly for specialty coated paper applications. These rolls endure significant mechanical stress, thermal fluctuations, and chemical exposure from the coating formulations. Therefore, selecting materials that can withstand these harsh conditions while maintaining dimensional stability and surface integrity is paramount. Common materials for precision-ground rolls in coating applications include high-grade steel alloys, stainless steel, and sometimes even specialized composites. The choice of material depends on factors such as the type of coating being applied, the operating speed of the paper machine, and the desired lifespan of the roll. For instance, stainless steel is often preferred for its corrosion resistance when dealing with water-based coatings, while certain steel alloys might be selected for their superior hardness and wear resistance in demanding, high-speed coating operations. The interplay between material selection and precision grinding is what ultimately determines the roll's performance and longevity.

The Art and Science of Precision Grinding

Precision grinding is not merely a manufacturing process; it's an art form that demands specialized skills and advanced machinery. Creating rolls with micron-level accuracy requires sophisticated grinding equipment, highly trained operators, and rigorous quality control measures. The process typically involves multiple stages of grinding, starting with rough grinding to remove excess material and achieve the approximate desired shape, followed by increasingly finer grinding steps to refine the surface finish and dimensional accuracy. Advanced techniques like CNC (Computer Numerical Control) grinding are often employed to ensure consistent and repeatable precision across the entire roll surface. Furthermore, specialized grinding wheels and coolants are used to minimize heat generation and prevent thermal distortion of the roll during the process. The entire grinding operation is meticulously monitored, with in-process measurements and final inspections using precision instruments to verify that the rolls meet the stringent specifications required for specialty coated paper production. This dedication to precision grinding is what separates standard rolls from those designed for high-performance coating applications.

Benefits Beyond Compare: Quality and Efficiency Gains

Investing in precision-ground paper machine rolls for specialty coated papers yields a multitude of benefits that directly impact both product quality and operational efficiency. Firstly, and perhaps most importantly, they lead to a significant improvement in the quality of the coated paper. The uniform coating application achieved with these rolls results in papers with consistent gloss, smoothness, ink receptivity, and other critical properties. This enhanced quality translates to higher customer satisfaction and reduced rejection rates. Secondly, precision rolls contribute to increased production efficiency. By minimizing coating defects and web breaks, they reduce downtime and material waste. Furthermore, their durability and resistance to wear mean longer roll life, decreasing the frequency of roll changes and maintenance. In the long run, while the initial investment in precision-ground rolls might be higher, the overall cost of ownership is often lower due to these gains in quality, efficiency, and longevity. It's a strategic investment that pays dividends in improved product performance and streamlined operations.

Applications Across the Spectrum of Specialty Papers

The demand for precision-ground paper machine rolls spans a wide array of specialty coated paper applications, each with its unique requirements. In the realm of graphic arts papers, for instance, where image quality is paramount, these rolls are essential for producing papers with exceptional printability for brochures, magazines, and high-end marketing materials. For packaging papers, where barrier properties and surface finish are critical, precision rolls ensure consistent coating coverage for applications like food packaging and pharmaceutical labels. Technical papers, such as release liners and pressure-sensitive adhesive papers, also rely heavily on the accuracy of coating application, making precision rolls indispensable. Even in industrial applications, like abrasive papers and filter papers, the uniformity and controlled properties imparted by precision-ground rolls are vital for performance. From the glossy pages of a luxury magazine to the functional surface of a release liner, precision-ground paper machine rolls are the unsung heroes behind the quality and performance of countless specialty coated paper products we encounter daily. Have you ever considered how many different types of specialty papers you interact with every day without realizing the precision engineering behind their creation?

Maintaining Precision: Care and Longevity of Rolls

While precision-ground paper machine rolls are engineered for durability, maintaining their optimal performance over time requires proper care and maintenance. Regular inspection is crucial to identify any signs of wear, damage, or coating buildup. This includes visual checks for surface defects, as well as dimensional measurements to monitor for any deviations from the original specifications. Cleaning is another essential aspect of maintenance. Coating residues and contaminants can accumulate on the roll surface, affecting coating uniformity and potentially leading to damage. Appropriate cleaning procedures, using recommended solvents and techniques, are necessary to keep the rolls in top condition. Furthermore, proper storage and handling practices are important to prevent accidental damage during roll changes or when rolls are not in use. By implementing a proactive maintenance program, paper manufacturers can maximize the lifespan of their precision-ground rolls and ensure consistent coating quality over extended periods. It’s a commitment to preventative care that pays off in long-term performance and cost-effectiveness.

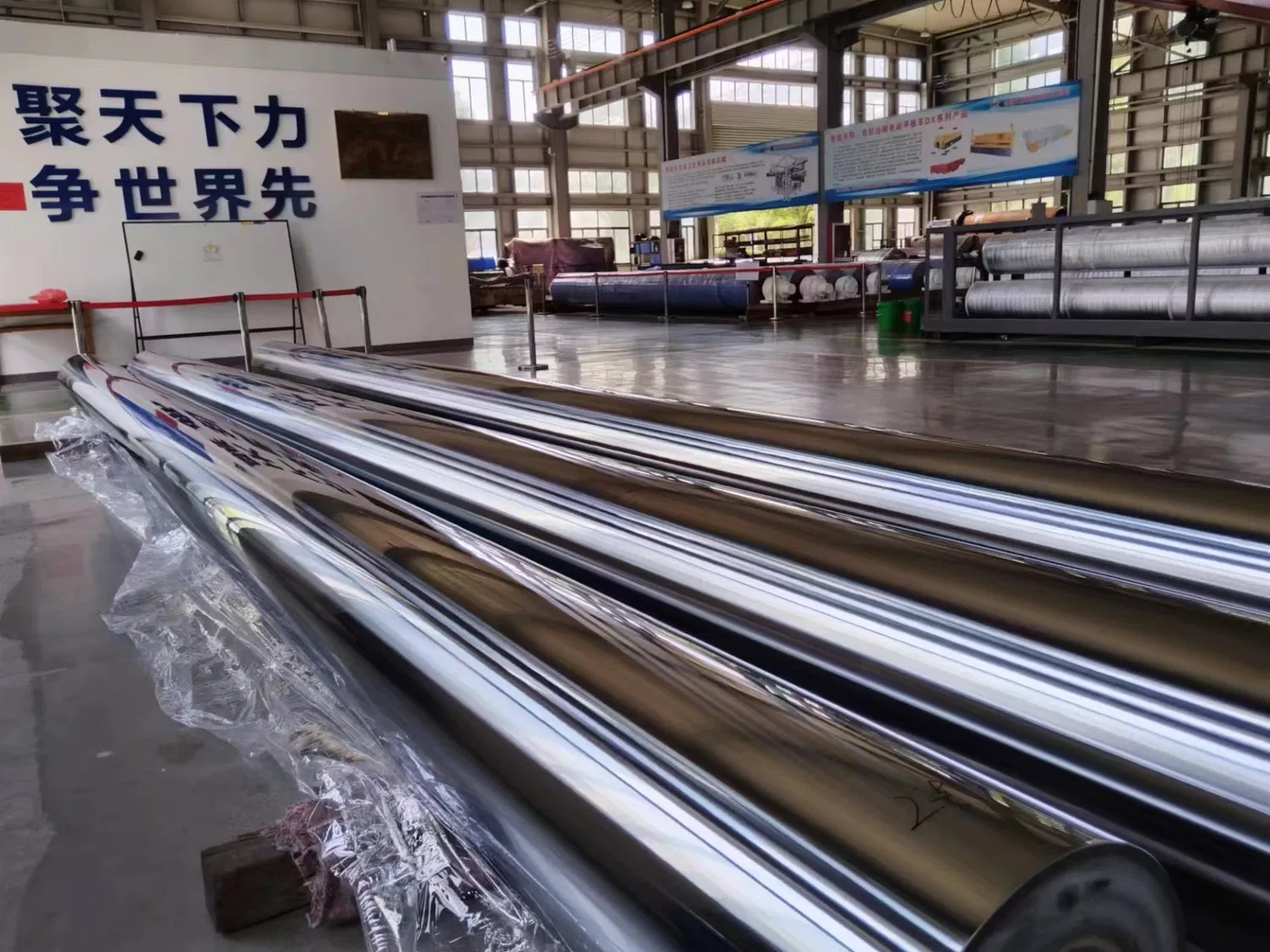

Our Commitment to Precision: Solutions for Your Coating Needs

At our company, we understand the critical role that precision-ground paper machine rolls play in the production of high-quality specialty coated papers. We are dedicated to providing our customers with rolls that meet the most demanding specifications, utilizing advanced grinding technology and rigorous quality control processes. Our rolls are manufactured from premium materials, carefully selected to match the specific requirements of each application. We offer a comprehensive range of precision-ground rolls, tailored for various coating methods and paper types. Furthermore, we provide expert technical support and consultation to help our customers optimize their coating operations and ensure the longevity of their rolls. We believe that investing in precision is investing in quality, efficiency, and ultimately, the success of our customers in the competitive specialty coated paper market. Frankly speaking, the difference that high-quality, precision-ground rolls can make to your final product is often underestimated, yet profoundly impactful.

For more detailed information, please visit our official website: Precision-Ground Rolls

`