In the demanding world of industrial operations, guide roll bearing systems play a pivotal role in ensuring smooth and efficient material handling, linear motion, and conveyor systems. These critical components are often subjected to harsh environments, characterized by extreme temperatures, excessive dust, corrosive chemicals, high humidity, and heavy loads. The challenge for engineers and maintenance professionals lies in selecting and implementing bearing solutions that not only withstand these punishing conditions but also deliver an extended service life, minimizing downtime, reducing replacement costs, and maintaining operational efficiency. Understanding the specific demands of harsh environments and the available options for enhancing bearing durability is paramount for achieving optimal system performance and longevity. This article delves into the intricacies of guide roll bearing systems in harsh environments, exploring key considerations and strategies for maximizing their operational lifespan.

Understanding Harsh Environments and Their Impact on Bearings

Harsh environments encompass a wide spectrum of challenging conditions that can significantly accelerate bearing wear and failure. Imagine a steel mill where bearings are constantly exposed to extreme heat, abrasive dust, and heavy vibrations. Or consider a chemical processing plant where bearings must operate reliably in the presence of corrosive fumes and liquids. Even seemingly innocuous environments like food processing plants present their own challenges, requiring bearings to withstand frequent washdowns with harsh cleaning agents and operate under varying temperature conditions. These diverse scenarios highlight the need for a nuanced approach to bearing selection and maintenance. Factors such as temperature extremes, whether excessively hot or cold, can drastically alter lubricant viscosity and material properties, leading to premature wear. Contamination from dust, dirt, and debris can act as abrasives, grinding away at bearing surfaces. Chemical exposure can corrode bearing components, weaken seals, and degrade lubricants. Understanding the specific harsh conditions present in an application is the crucial first step in selecting a guide roll bearing system that can deliver extended service life.

Material Selection: Fortifying Bearings Against Degradation

One of the most fundamental strategies for enhancing the service life of guide roll bearings in harsh environments lies in the careful selection of bearing materials. Standard bearing steel, while suitable for many applications, may not be sufficient in particularly aggressive conditions. For instance, in environments prone to corrosion, stainless steel bearings offer superior resistance compared to conventional steel. Different grades of stainless steel provide varying levels of corrosion protection, allowing engineers to tailor material selection to the specific chemical exposure risks. Ceramic bearings, particularly those made of silicon nitride, represent another advanced material option. Ceramics boast exceptional hardness, high-temperature resistance, and corrosion immunity. While often more expensive than steel bearings, their extended lifespan and reduced maintenance requirements in extreme environments can justify the initial investment. Furthermore, hybrid bearings, combining steel races with ceramic rolling elements, offer a balanced approach, leveraging the advantages of both materials. The choice of cage material is also critical. Steel cages are common, but in corrosive or high-temperature environments, brass, stainless steel, or even polymer cages may be more appropriate to ensure structural integrity and prevent degradation.

Effective Sealing Solutions: Keeping Contaminants Out

Maintaining a clean and contaminant-free operating environment within a bearing is essential for prolonging its service life, especially in harsh conditions. Effective sealing systems act as the first line of defense against the ingress of dust, dirt, moisture, and other harmful substances. Various sealing options are available, each offering different levels of protection and friction. Contact seals, such as lip seals, provide a robust barrier against contamination but can generate friction and heat, potentially limiting high-speed applications. Non-contact seals, like labyrinth seals, offer lower friction and are suitable for higher speeds, but may not provide the same level of protection against fine contaminants or liquids. For extremely dusty or contaminated environments, multi-lip seals or specialized sealing arrangements incorporating deflectors and grease purging systems can offer enhanced protection. The selection of seal material is also crucial, with options ranging from nitrile rubber and Viton to PTFE, each offering different levels of resistance to temperature, chemicals, and wear. Proper seal installation and maintenance are equally important to ensure their effectiveness. Regular inspection for damage or wear and timely replacement are key to maintaining the integrity of the sealing system and protecting the bearing from contamination.

Lubrication Strategies: Minimizing Friction and Wear

Lubrication is the lifeblood of any bearing system, and its importance is amplified in harsh environments. Proper lubrication minimizes friction, reduces wear, dissipates heat, and protects bearing surfaces from corrosion. In harsh conditions, selecting the right lubricant and lubrication method is critical for extended service life. Grease lubrication is commonly used for guide roll bearings due to its simplicity and ability to provide a barrier against contaminants. However, in high-temperature environments, standard greases may degrade and lose their lubricating properties. High-temperature greases, formulated with synthetic base oils and special additives, are designed to withstand elevated temperatures and maintain their viscosity and lubricating film. For extremely low-temperature applications, low-temperature greases are necessary to prevent stiffening and ensure adequate lubrication. Oil lubrication, while more complex to implement, can offer superior cooling and contaminant flushing capabilities, particularly in heavily loaded or high-speed applications. Circulating oil lubrication systems can continuously supply clean, cooled oil to the bearings, extending lubricant life and improving bearing performance. Regardless of the lubricant type, regular relubrication at appropriate intervals is crucial, especially in harsh environments where contaminants may degrade the lubricant more quickly. Implementing an effective lubrication management program, including proper lubricant selection, relubrication schedules, and contamination control measures, is essential for maximizing bearing life.

Design Considerations for Extended Durability

Beyond material selection, sealing, and lubrication, several design considerations can contribute to the extended service life of guide roll bearing systems in harsh environments. Bearing size and load capacity should be carefully matched to the application requirements, with a safety factor to account for unexpected loads or shock conditions. Larger bearings generally have a longer fatigue life and can better withstand heavy loads. Internal bearing clearance is another important design parameter. In high-temperature environments, thermal expansion can reduce bearing clearance, potentially leading to preload and premature failure. Bearings with increased internal clearance (C3 or C4) can accommodate thermal expansion and maintain proper operating clearance. Bearing mounting and housing design also play a role in bearing performance. Rigid and accurately machined housings provide proper support and alignment, minimizing stress concentrations and vibration. Housings designed with features to facilitate relubrication and seal replacement can simplify maintenance and extend bearing life. Furthermore, incorporating features like grease fittings, drain plugs, and inspection ports into the housing design can enhance maintenance accessibility and efficiency. By carefully considering these design aspects, engineers can create guide roll bearing systems that are inherently more robust and resilient in harsh operating conditions.

Proactive Maintenance and Condition Monitoring

Even with the best bearing selection and design, proactive maintenance is essential for maximizing the service life of guide roll bearing systems in harsh environments. Regular inspections, lubrication, and timely component replacement are crucial elements of a comprehensive maintenance program. Visual inspections can detect early signs of bearing distress, such as grease leakage, contamination, or external damage. Vibration analysis is a powerful condition monitoring technique that can detect subtle changes in bearing condition long before they become apparent through visual inspection. By analyzing vibration patterns, maintenance professionals can identify bearing defects, imbalance, misalignment, and lubrication issues. Thermography, or infrared thermal imaging, can detect abnormal temperature increases in bearings, which can indicate friction, overloading, or lubrication problems. Regular lubricant analysis can assess the condition of the lubricant, identify contaminants, and determine if relubrication or lubricant change is needed. Implementing a condition-based maintenance program, utilizing these monitoring techniques, allows for proactive intervention, preventing catastrophic failures and extending bearing service life. By detecting and addressing potential problems early, maintenance costs can be significantly reduced, and system uptime can be maximized.

Applications Across Diverse Industries

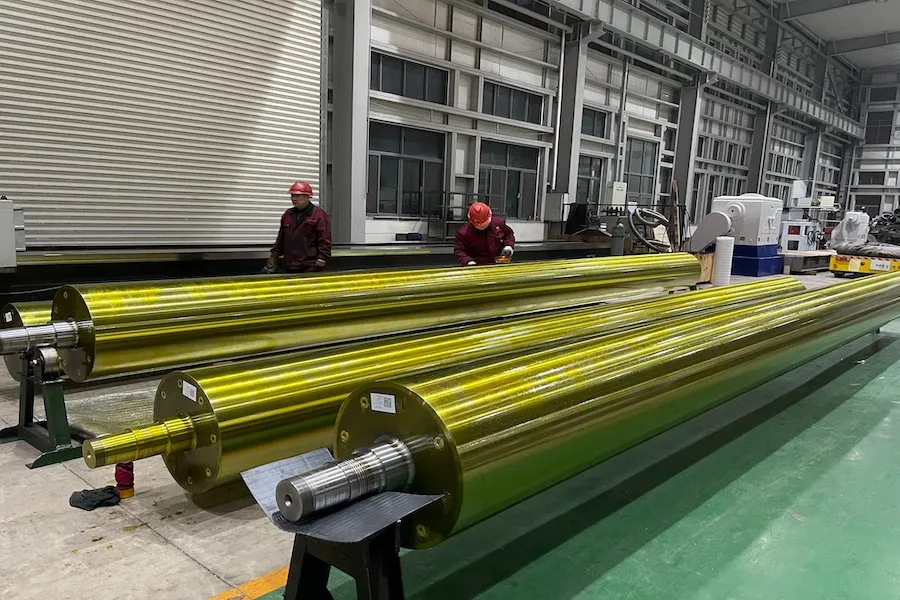

Guide roll bearing systems designed for harsh environments find applications across a wide range of industries where reliability and durability are paramount. In the mining and mineral processing industry, these bearings are crucial in conveyor systems, crushers, and screening equipment, operating under heavy loads and in dusty, abrasive environments. Steel mills and metal processing plants utilize guide roll bearings in rolling mills, continuous casters, and coil handling equipment, where they must withstand extreme temperatures, heavy loads, and vibrations. Cement plants present similarly challenging conditions with high dust levels and abrasive materials. In the pulp and paper industry, bearings are exposed to moisture, chemicals, and varying temperatures. Food and beverage processing facilities require bearings that can withstand frequent washdowns and operate in hygienic environments. Chemical processing plants demand bearings resistant to corrosive chemicals and extreme temperatures. Power generation, including wind turbines and conventional power plants, relies on robust bearings for critical rotating equipment operating under demanding conditions. Across these diverse applications, the selection of appropriate guide roll bearing systems with features tailored for harsh environments is essential for ensuring operational reliability and minimizing downtime. Have you ever considered the specific bearing requirements in your own industrial setting? Understanding these needs is the first step towards optimizing your system's performance and longevity.

Our Solutions for Harsh Environment Bearing Challenges

At our company, we understand the critical importance of reliable guide roll bearing systems in harsh operating environments. We offer a comprehensive range of bearing solutions specifically engineered to withstand the rigors of demanding industrial applications. Our product portfolio includes bearings manufactured from advanced materials like stainless steel and ceramics, providing superior corrosion and wear resistance. We offer a wide selection of sealing options, from robust contact seals to low-friction non-contact seals, ensuring optimal protection against contamination in various environments. Our bearings are designed with optimized internal clearances and robust cage designs to accommodate thermal expansion and heavy loads. We also provide specialized lubrication solutions, including high-performance greases and circulating oil systems, to ensure effective lubrication and cooling in extreme temperature conditions. Furthermore, our engineering team can provide expert guidance in bearing selection, application design, and maintenance strategies, helping our customers optimize their bearing systems for extended service life and reduced downtime. We are committed to providing reliable, high-performance bearing solutions that meet the unique challenges of harsh environments, enabling our customers to achieve operational excellence and maximize productivity. Frankly speaking, choosing the right bearing partner is just as crucial as choosing the right bearing itself. We strive to be that partner for our customers.

Conclusion: Ensuring Extended Service Life in Demanding Applications

In conclusion, guide roll bearing systems operating in harsh environments face significant challenges that can impact their service life and overall system performance. However, by carefully considering material selection, implementing effective sealing and lubrication strategies, optimizing bearing design, and adopting proactive maintenance practices, it is possible to significantly extend the operational lifespan of these critical components. Choosing the right bearing for a harsh environment is not merely about selecting a standard part; it's about understanding the specific demands of the application and tailoring the bearing system to meet those challenges. This includes selecting appropriate materials resistant to corrosion and wear, implementing robust sealing solutions to prevent contamination, choosing lubricants that can withstand extreme temperatures and operating conditions, and designing bearing housings and mounting arrangements that provide proper support and facilitate maintenance. By embracing a holistic approach that encompasses these considerations, industries can ensure the reliable and extended operation of their guide roll bearing systems, even in the most demanding environments, ultimately minimizing downtime, reducing costs, and maximizing productivity. It's worth noting that the initial investment in higher-quality, application-specific bearings often pays off significantly in the long run through reduced maintenance and replacement costs, and increased operational uptime. The key is to proactively address the challenges posed by harsh environments and implement strategies to mitigate their impact on bearing performance and longevity.

For more detailed information, please visit our official website: guide roll bearings