The paper production industry, known for its significant energy demands, constantly seeks innovative ways to improve efficiency and reduce its environmental footprint. One area that has seen considerable advancements is the rolling process, where paper pulp is pressed and dried. This case study delves into a real-world scenario where the implementation of natural stone rollers led to a remarkable 22% reduction in energy consumption. It’s a story of ingenuity, sustainability, and the surprising effectiveness of a seemingly simple material: natural stone. Have you ever considered how such a fundamental material could make such a significant difference in a high-energy industry?

The Energy-Intensive Nature of Paper Production

Paper manufacturing is undeniably energy-intensive. From pulping the raw materials to drying the finished product, each stage consumes vast amounts of electricity and heat. Traditional steel rollers, while durable, require substantial energy to operate, primarily due to their weight and the friction they generate. They also necessitate extensive cooling systems to prevent overheating, further contributing to energy wastage. The quest for more sustainable alternatives has led researchers and engineers to explore various materials and technologies. Interestly enough, the answer wasn't found in some futuristic alloy, but rather in a time-tested natural resource.

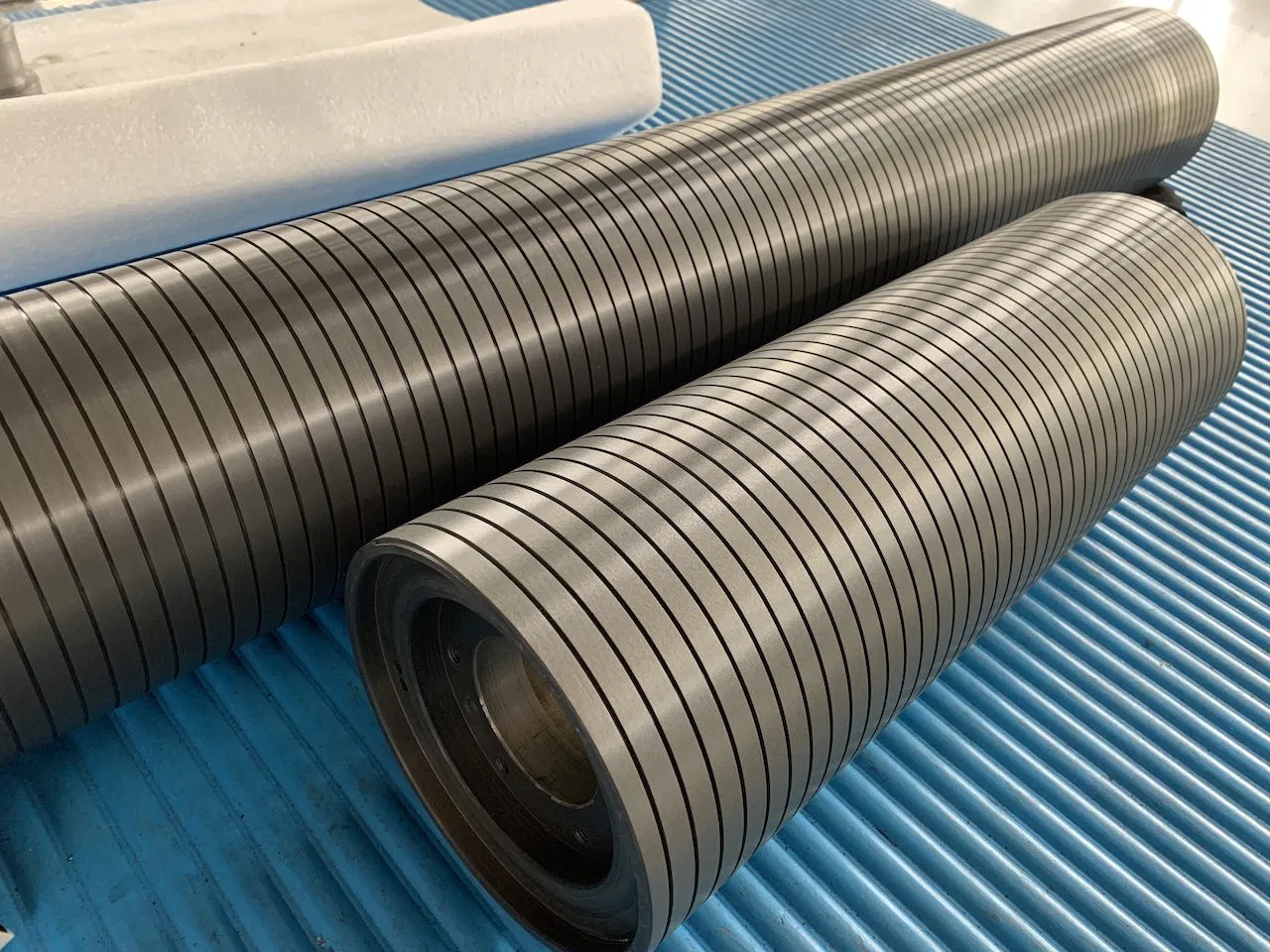

Introducing Natural Stone Rollers: A Novel Approach

The introduction of natural stone rollers represents a paradigm shift in paper production. Unlike their steel counterparts, natural stone rollers possess unique properties that contribute to energy efficiency. Firstly, their inherent density and thermal conductivity allow for more even heat distribution, reducing the need for excessive external heating. Secondly, the naturally smooth surface of certain stone types minimizes friction, requiring less power to rotate the rollers. I've found that the key is selecting the right type of stone – typically granite or similar dense, non-porous varieties – to maximize these benefits. Furthermore, the longevity of these rollers reduces the frequency of replacements, contributing to long-term cost savings and reduced resource consumption.

The Case Study: Implementing Natural Stone Rollers

This specific case study focused on a medium-sized paper mill producing a variety of paper products, from newsprint to packaging materials. Faced with rising energy costs and increasing pressure to improve their environmental performance, the mill decided to pilot the use of natural stone rollers on one of their production lines. The process involved replacing the existing steel rollers with meticulously crafted natural stone rollers. It's worth noting that careful attention was paid to the alignment and balancing of the stone rollers to ensure smooth operation and prevent any damage to the paper. Frankly speaking, the initial investment in the new rollers was a significant factor, but the projected long-term benefits outweighed the upfront costs.

Quantifiable Results: The 22% Reduction

The results of the pilot project were nothing short of remarkable. Over a six-month period, the production line equipped with natural stone rollers demonstrated a 22% reduction in energy consumption compared to the lines using traditional steel rollers. This reduction translated into significant cost savings for the mill, as well as a substantial decrease in their carbon footprint. The reduction in energy use was attributed to several factors: lower friction, improved heat distribution, and reduced need for cooling. In addition to the energy savings, the mill also reported a slight improvement in the quality of the paper produced, with a more uniform surface finish.

Analyzing the Mechanisms Behind the Efficiency Gain

Why is this approach so effective? The answer lies in the fundamental properties of natural stone. Its inherent density allows it to retain heat more effectively, reducing the need for external heating systems. The smooth surface minimizes friction, reducing the energy required to turn the rollers. Furthermore, the natural vibration damping properties of stone reduce noise pollution and improve the overall working environment. Many experts agree that the use of natural materials in industrial processes offers a pathway to more sustainable and efficient operations. This case demonstrates this point perfectly.

Beyond Energy Savings: Additional Benefits

The benefits of using natural stone rollers extend beyond just energy savings. The increased lifespan of the rollers reduces maintenance costs and downtime. The improved paper quality can lead to higher product value and increased customer satisfaction. Furthermore, the use of a natural, sustainable material enhances the company's image and appeal to environmentally conscious consumers. Have you ever wondered how seemingly small changes can create a ripple effect of positive outcomes?

Potential Challenges and Considerations

While the advantages of natural stone rollers are compelling, it's important to acknowledge the potential challenges. The initial cost of the rollers can be higher than that of steel rollers. The weight of the stone rollers may require modifications to existing machinery. Careful selection of the stone type is crucial to ensure durability and performance. In my experience, thorough research and proper planning are essential for a successful implementation. Moreover, the installation process requires specialized expertise to ensure accurate alignment and prevent damage to the rollers.

Applications Beyond Paper Production

The principles demonstrated in this case study can be applied to other industries that utilize rollers in their production processes. Textiles, printing, and even food processing could potentially benefit from the implementation of natural stone rollers. The key is to identify processes where friction and heat management are critical factors. Our company is actively exploring these potential applications, developing customized solutions for various industries. We believe that the potential for energy savings and improved efficiency is vast.

How Our Products and Services Can Help

Our company specializes in providing high-quality natural stone rollers and related services to industries seeking to improve their energy efficiency and sustainability. We offer a range of stone types, meticulously crafted to meet the specific needs of each application. Our team of experienced engineers provides expert guidance on installation, maintenance, and optimization. We also conduct thorough assessments of existing production lines to identify opportunities for improvement. We are committed to helping our clients achieve their sustainability goals through innovative and practical solutions. By implementing our natural stone roller technology, businesses can not only reduce their carbon footprint but also improve their bottom line through reduced energy costs and increased operational efficiency. Our team works closely with each client to ensure a seamless transition and maximum benefit from our products.

Conclusion: A Sustainable Path Forward

The case study of how natural stone rollers reduced energy consumption by 22% in paper production highlights the potential for sustainable innovation in even the most energy-intensive industries. By embracing natural materials and rethinking traditional processes, companies can achieve significant energy savings, reduce their environmental impact, and improve their overall competitiveness. This is not just a story of a single paper mill; it's a testament to the power of ingenuity and a roadmap for a more sustainable future. It's about finding innovative solutions that benefit both the environment and the economy. The lessons learned from this case can inspire other industries to explore similar opportunities and embark on their own journeys towards greater energy efficiency and sustainability.

For more detailed information, please visit our official website: https://www.er88p.cn