The integration of natural stone rollers into existing paper machinery represents a significant upgrade for many paper manufacturers. These rollers, prized for their unique properties and ability to impart a superior finish to paper, require careful installation to ensure optimal performance and longevity. This guide outlines the essential steps and considerations for a successful integration process. From initial assessments and preparations to the final adjustments and testing, we'll cover everything you need to know to seamlessly incorporate natural stone rollers into your established paper production line. Have you ever wondered how a seemingly simple change of rollers can drastically improve paper quality? This guide aims to answer that and more.

Understanding Natural Stone Rollers and Their Benefits

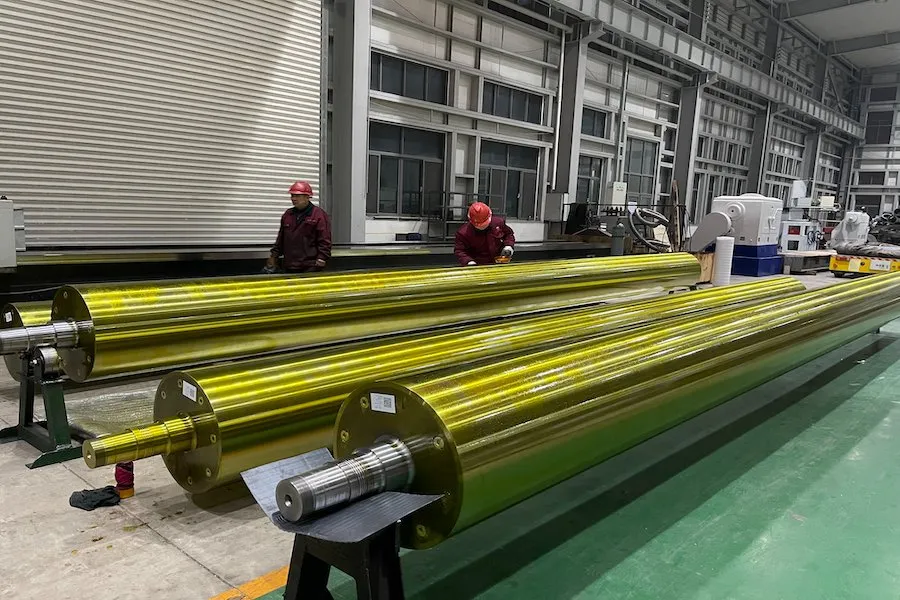

Natural stone rollers, typically crafted from granite or similar durable stone types, offer several advantages over traditional metal rollers. Their inherent properties allow for consistent pressure distribution, which minimizes imperfections and enhances the smoothness of the paper surface. Furthermore, the natural composition of the stone contributes to reduced static electricity, a common issue in paper production that can lead to dust accumulation and handling problems. The benefits extend beyond paper quality; natural stone rollers often exhibit superior wear resistance, leading to a longer lifespan and reduced maintenance requirements. It's worth noting, however, that proper handling and installation are crucial to maximizing these benefits. Choosing the right type of stone roller for your specific paper grade and machinery is also a vital preliminary step. Different stone types possess varying hardness and texture characteristics, impacting the final paper finish. Frankly speaking, investing in quality natural stone rollers can significantly elevate the quality of your paper products and increase operational efficiency.

Pre-Installation Assessment and Planning

Before commencing the installation process, a thorough assessment of your existing paper machinery is paramount. This involves examining the compatibility of the stone rollers with your current setup, considering factors such as roller dimensions, bearing types, and load-bearing capacity. Detailed measurements should be taken to ensure a precise fit, and any necessary modifications to the machine frame or support structures should be identified. A detailed installation plan should be developed, outlining the sequence of steps, required tools, and safety precautions. It is also prudent to consult with our company's technical experts, who can provide valuable insights and recommendations based on their extensive experience. Moreover, determine if any specialized lifting equipment is needed, considering the weight and delicate nature of the stone rollers. Failure to properly assess and plan can lead to costly delays and potential damage to the rollers or machinery. In my experience, spending adequate time on this initial phase yields significant dividends later on.

Preparing the Machinery for Roller Installation

Once the assessment and planning phases are complete, the next step is to prepare the existing paper machinery for the new rollers. This typically involves cleaning and inspecting the bearing housings, ensuring they are free from debris and corrosion. Worn or damaged bearings should be replaced to prevent premature wear and ensure smooth roller operation. The roller mounting surfaces should be thoroughly cleaned and leveled to provide a stable and even platform for the stone rollers. Careful attention should also be paid to the lubrication system, ensuring it is functioning correctly and supplying adequate lubrication to the bearings. It's important to use the correct type of lubricant recommended for the specific bearings and operating conditions. The machine should be powered down and properly locked out/tagged out (LOTO) to ensure the safety of personnel during the installation process. Remember, safety should always be the top priority.

The Installation Process: A Step-by-Step Guide

The actual installation process should be carried out with meticulous care and precision. Using appropriate lifting equipment, carefully position the natural stone rollers onto the prepared mounting surfaces. Ensure the rollers are aligned correctly and that the bearing housings are properly seated. Gradually tighten the mounting bolts, following a specific torque sequence recommended by the manufacturer. This ensures even pressure distribution and prevents stress concentrations. After tightening the bolts, double-check the alignment and level of the rollers. Any misalignment can lead to uneven paper thickness and premature wear. It is also advisable to use shims if necessary to achieve perfect alignment. Throughout the installation process, avoid any sudden impacts or jarring movements that could damage the delicate stone rollers. Many experts agree that patience and attention to detail are key to a successful installation.

Post-Installation Checks and Adjustments

Following the roller installation, several post-installation checks and adjustments are necessary to ensure optimal performance. Verify the roller parallelism and nip pressure across the entire width of the machine. The nip pressure should be adjusted according to the specifications for the paper grade being produced. Inspect the lubrication system to ensure proper oil flow to the bearings. Run the machine at a slow speed initially, monitoring for any unusual vibrations, noises, or temperature increases. If any abnormalities are detected, stop the machine immediately and investigate the cause. Minor adjustments may be required to fine-tune the roller alignment or nip pressure. These adjustments should be made gradually and systematically, observing the effect on paper quality. To be honest, this stage is crucial for guaranteeing smooth and efficient operation. Our company can also provide on-site support to supervise the installation and ensure all parameters are within optimal ranges.

Troubleshooting Common Issues

Even with careful installation, some common issues may arise after integrating natural stone rollers. Uneven paper thickness could indicate misalignment or uneven nip pressure. Vibration problems could be caused by loose mounting bolts or damaged bearings. Excessive roller wear might suggest inadequate lubrication or abrasive contaminants. Static electricity buildup can be minimized by grounding the rollers or using anti-static sprays. These issues are generally easily solvable with minor adjustments or proper maintenance. Addressing these issues promptly can prevent further damage and ensure consistent paper quality. Furthermore, consider consulting our technical support team for guidance and troubleshooting assistance. We can provide valuable insights and solutions based on our extensive experience with natural stone rollers and paper machinery.

Maintenance and Long-Term Care

To maximize the lifespan and performance of your natural stone rollers, a regular maintenance program is essential. This includes routine cleaning to remove paper dust and contaminants, regular lubrication of the bearings, and periodic inspections for wear and damage. Avoid using harsh chemicals or abrasive cleaners that could damage the stone surface. Inspect the roller surface regularly for any signs of cracks or chips. If any damage is detected, consult with a qualified technician for repair or replacement. Keep detailed maintenance records to track the performance of the rollers and identify any potential issues early on. Proper maintenance will not only extend the life of your rollers but also help to maintain consistent paper quality. Interestingly enough, with proactive care, natural stone rollers can last for many years, providing a worthwhile return on investment.

Conclusion: Embracing the Benefits of Natural Stone Rollers

The integration of natural stone rollers into existing paper machinery, while requiring careful planning and execution, offers substantial benefits in terms of paper quality, operational efficiency, and long-term cost savings. By following this installation guide and adhering to proper maintenance practices, paper manufacturers can unlock the full potential of these exceptional rollers and enhance their competitive edge. We at our company believe that embracing innovation and investing in high-quality equipment, like natural stone rollers, is crucial for success in the ever-evolving paper industry. Our expertise and range of services in this area will ensure smooth operations for your manufacturing lines. What long-term benefits do you hope to achieve by integrating natural stone rollers into your paper production process?

For more detailed information, please visit our official website: https://www.er88p.cn