The age-old debate in the papermaking industry often revolves around the materials used to create the rollers that are integral to the process. Specifically, the comparison between natural stone rollers and composite rollers sparks considerable discussion. Both have their unique strengths and weaknesses, directly influencing the final paper quality and the overall production speed. Choosing the right roller type can significantly impact a paper mill's efficiency, cost-effectiveness, and the quality of its output. Have you ever wondered how seemingly simple rollers could have such a profound impact?

Natural Stone Rollers: A Time-Tested Approach

For centuries, natural stone rollers have been the mainstay in paper production. Historically, they were favored for their inherent properties: exceptional hardness, uniform density, and a naturally smooth surface. These characteristics translate to several key advantages. First, the hardness of natural stone ensures durability and longevity, reducing the frequency of replacements and downtime. Second, the consistent density contributes to even pressure distribution across the paper web, minimizing imperfections and ensuring a uniform finish. Third, the smooth surface of the stone minimizes friction, which in turn prevents tearing or damage to the delicate paper fibers, ultimately leading to higher-quality paper with fewer defects. Interestingly enough, the very nature of the stone provides a certain level of "forgiveness" in the process, allowing for slight variations in pulp consistency without drastically affecting the final product.

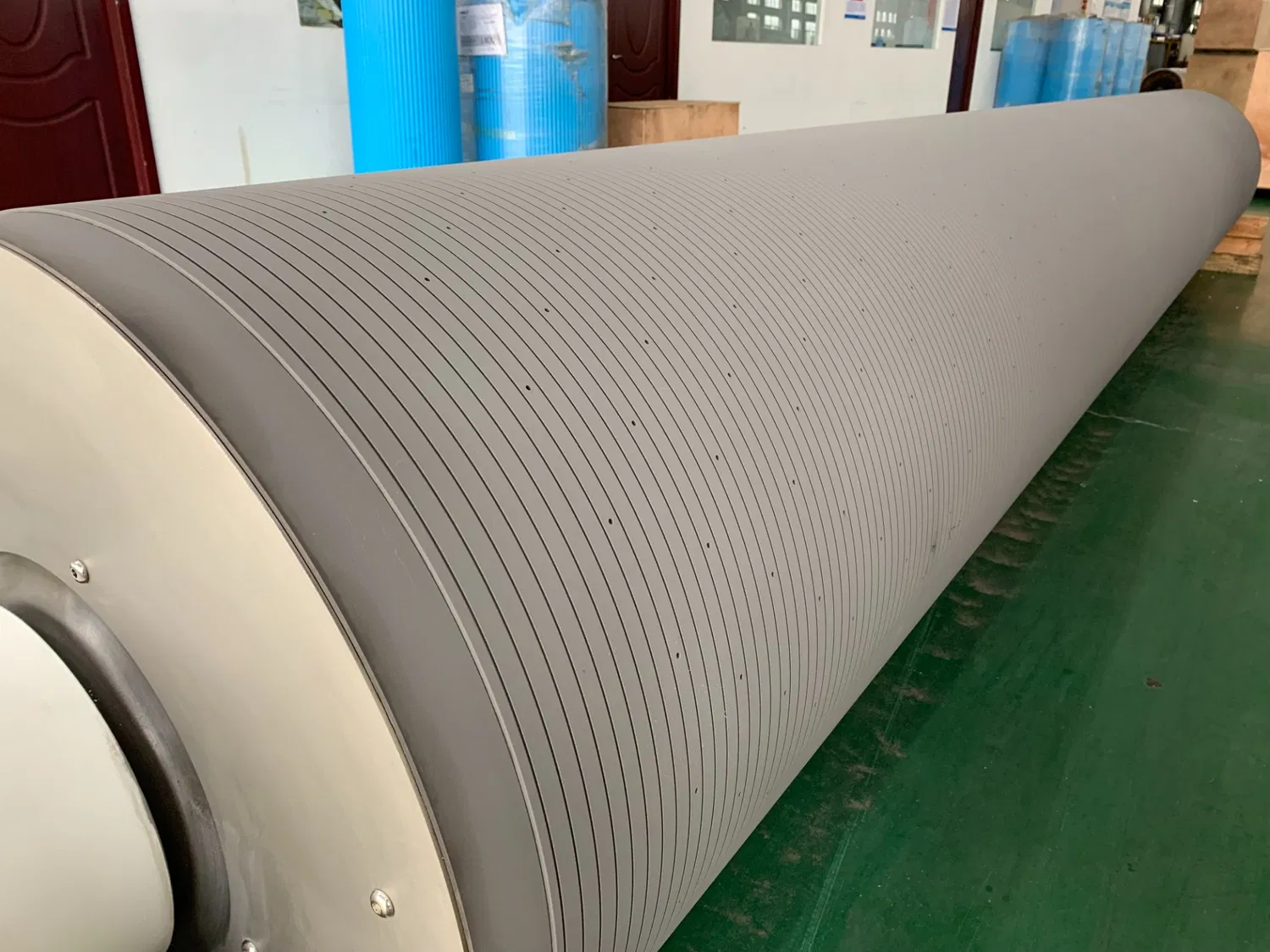

Composite Rollers: The Modern Alternative

Composite rollers, on the other hand, represent a more modern approach. These rollers are typically constructed from a combination of materials, such as polymers, ceramics, and various additives, carefully engineered to achieve specific properties. One of the primary advantages of composite rollers lies in their versatility. Manufacturers can precisely tailor the composition of the composite material to meet specific requirements, optimizing for factors like abrasion resistance, chemical inertness, and thermal stability. Furthermore, composite rollers often boast lighter weight compared to their natural stone counterparts, which can translate to reduced energy consumption and improved machine dynamics. Frankly speaking, the ability to fine-tune the properties of composite rollers offers a level of control that is simply not possible with natural stone.

Impact on Paper Quality: A Close Examination

The influence of roller material on paper quality is undeniable. Natural stone rollers, with their inherent smoothness and consistent pressure, tend to produce paper with a superior surface finish, particularly important for applications requiring high printability, such as magazines and high-end brochures. The gentle action of the stone helps to preserve the integrity of the paper fibers, resulting in a stronger and more durable sheet. Conversely, while composite rollers can be engineered to achieve a smooth surface, the potential for variations in material properties and surface irregularities can sometimes lead to minor imperfections in the paper, such as subtle variations in thickness or surface texture. However, advancements in composite materials and manufacturing processes are continually minimizing these drawbacks, leading to increasingly high-quality paper production.

Production Speed Considerations

Production speed is another critical factor to consider. Here, the lighter weight and potentially higher operating speeds of composite rollers can offer a significant advantage. The reduced inertia of composite rollers allows for faster acceleration and deceleration of the papermaking machine, leading to increased throughput. Natural stone rollers, while robust and durable, are generally heavier and require more energy to operate at higher speeds. This can lead to increased energy consumption and potentially limit the overall production capacity of the machine. It's worth noting that modern papermaking machines are designed to handle the weight of natural stone rollers, but the energy efficiency benefits of composite rollers can be a compelling argument in many cases. This, of course, affects not just the budget but the mill's environmental impact as well.

Durability and Maintenance: Long-Term Cost Implications

When evaluating the long-term cost-effectiveness of different roller types, durability and maintenance requirements are paramount. Natural stone rollers are renowned for their exceptional longevity, often lasting for decades with proper care. The inherent hardness of the stone makes them resistant to wear and tear, minimizing the need for frequent replacements. However, when damage does occur, repairing natural stone rollers can be a complex and costly process. Composite rollers, while potentially less durable than natural stone in some applications, offer the advantage of easier and more cost-effective repairs. The modular nature of composite materials allows for localized repairs without requiring complete roller replacement. In my experience, a well-maintained set of natural stone rollers can certainly outlast a composite set, but the maintenance cost associated with each should be carefully considered. Furthermore, the specific type of paper being produced and the operating conditions of the machine will significantly influence the lifespan of both roller types.

Applications and Suitability: Matching Rollers to Specific Needs

The choice between natural stone and composite rollers is not always a straightforward decision. The optimal choice depends on a variety of factors, including the type of paper being produced, the desired quality level, the operating conditions of the papermaking machine, and the budget constraints of the mill. For applications requiring exceptionally high surface finish and durability, such as fine art paper or security paper, natural stone rollers remain a popular choice. Conversely, for high-volume production of commodity papers, where speed and cost-effectiveness are paramount, composite rollers may offer a more compelling solution. Ultimately, a thorough assessment of the specific needs and priorities of the paper mill is essential for making an informed decision.

Future Trends: Innovations and Advancements

The papermaking industry is constantly evolving, and advancements in materials science and manufacturing technology are continually blurring the lines between natural stone and composite rollers. Researchers are developing new composite materials with enhanced properties, such as increased hardness, improved wear resistance, and superior surface finish. These innovations are paving the way for composite rollers that can rival, or even surpass, the performance of natural stone rollers in certain applications. Furthermore, advancements in sensor technology and process control are enabling more precise monitoring and optimization of the papermaking process, regardless of the roller material being used. As technology continues to advance, the distinction between natural stone and composite rollers may become less significant, with the focus shifting towards optimizing the overall papermaking process to achieve the desired quality and efficiency.

Making the Right Choice for Your Paper Mill

Choosing between natural stone and composite rollers is a critical decision that impacts both paper quality and production speed. The best option depends heavily on your specific needs, budget, and desired outcome. Are you prioritizing unparalleled surface finish or maximum throughput? Understanding these priorities is crucial. Our company understands the intricacies of both roller types and can offer expert guidance to help you make the optimal choice for your unique circumstances. We offer a range of roller solutions and support services to ensure that your papermaking process operates at peak efficiency and produces the highest quality paper possible.

For more detailed information, please visit our official website: https://www.er88p.cn