The Unseen Hero: Temperature Management in Paper Production

Temperature management might not be the first thing that comes to mind when you think about paper production, but it plays a crucial role in ensuring the smooth operation of paper machines. Proper temperature control helps maintain roll performance, minimize downtime, and extend roll life. In this article, we'll delve into the world of temperature management solutions for critical paper machine rolls and explore how these innovative technologies can benefit your paper production process.

Understanding the Challenges

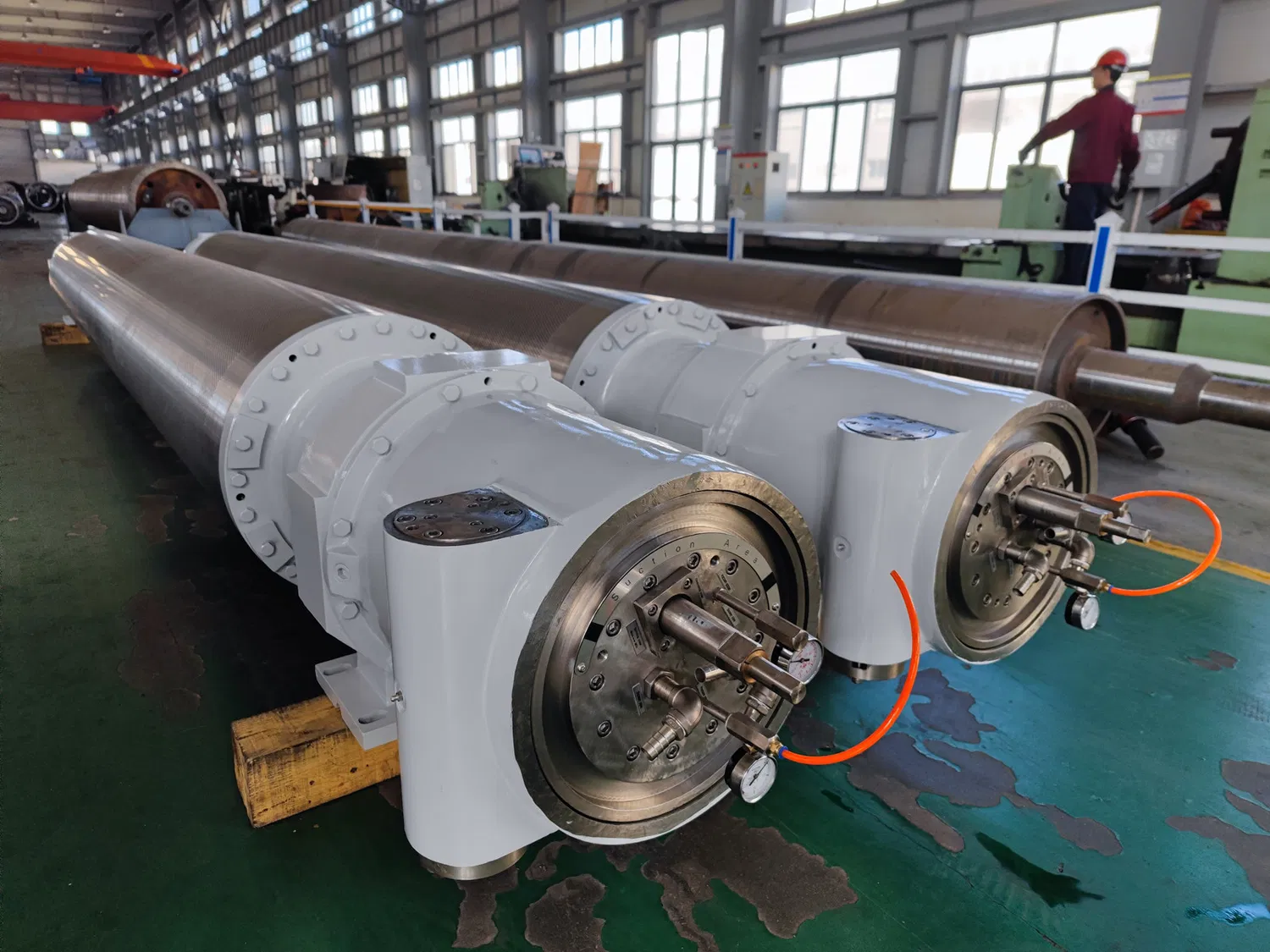

Paper machine rolls are subjected to immense heat and pressure, which can lead to various issues such as roll deformation, coating inconsistencies, and reduced efficiency. To combat these challenges, temperature management solutions have been developed to maintain optimal roll temperatures, ensuring consistent performance and minimizing maintenance requirements.

Innovative Temperature Management Solutions

Let's take a closer look at some of the cutting-edge temperature management solutions available for paper machine rolls:

1. Infrared Heating Systems

Infrared heating systems use radiant energy to heat the roll surface, providing fast and precise temperature control. This technology ensures even heat distribution, reducing the risk of hotspots and thermal stress on the rolls. Infrared heaters can be customized to fit various roll sizes and configurations, making them a versatile solution for paper mills.

2. Induction Heating Systems

Induction heating systems generate heat directly within the roll by inducing an electromagnetic field. This method offers rapid heating and cooling capabilities, allowing for precise temperature control. Additionally, induction heating systems are energy-efficient and require minimal maintenance.

3. Temperature Controlled Roll Covers

Temperature controlled roll covers are designed to maintain consistent roll temperatures by using advanced insulation materials. These covers help reduce heat loss and provide uniform thermal protection, ensuring optimal roll performance and extended roll life.

Real-World Applications and Benefits

So, how do these temperature management solutions translate to real-world benefits? Here are some examples:

- Improved product quality: Consistent roll temperatures lead to better coating application, resulting in higher-quality paper products.

- Reduced downtime: By minimizing roll deformation and wear, temperature management solutions help decrease maintenance requirements and increase machine uptime.

- Energy savings: Efficient temperature control can lead to significant energy savings, reducing operational costs and environmental impact.

How Our Company Can Help

At our company, we specialize in providing tailored temperature management solutions for paper machine rolls. Our team of experts works closely with clients to understand their unique challenges and develop customized solutions that maximize performance and minimize downtime. Reach out to us today to learn more about how our innovative temperature management technologies can benefit your paper production process.

For more detailed information, please visit our official website: https://www.er88p.cn