The Importance of Dynamic Balancing in High-Speed Paper Machines

Have you ever wondered why your high-speed paper machine isn't running as smoothly as it should? The answer could lie in the dynamic balancing of its rolls. In today's fast-paced industrial world, maintaining optimal performance is crucial. One way to achieve this is through dynamic balancing, which ensures that your paper machine rolls are running vibration-free.

Understanding Dynamic Balancing

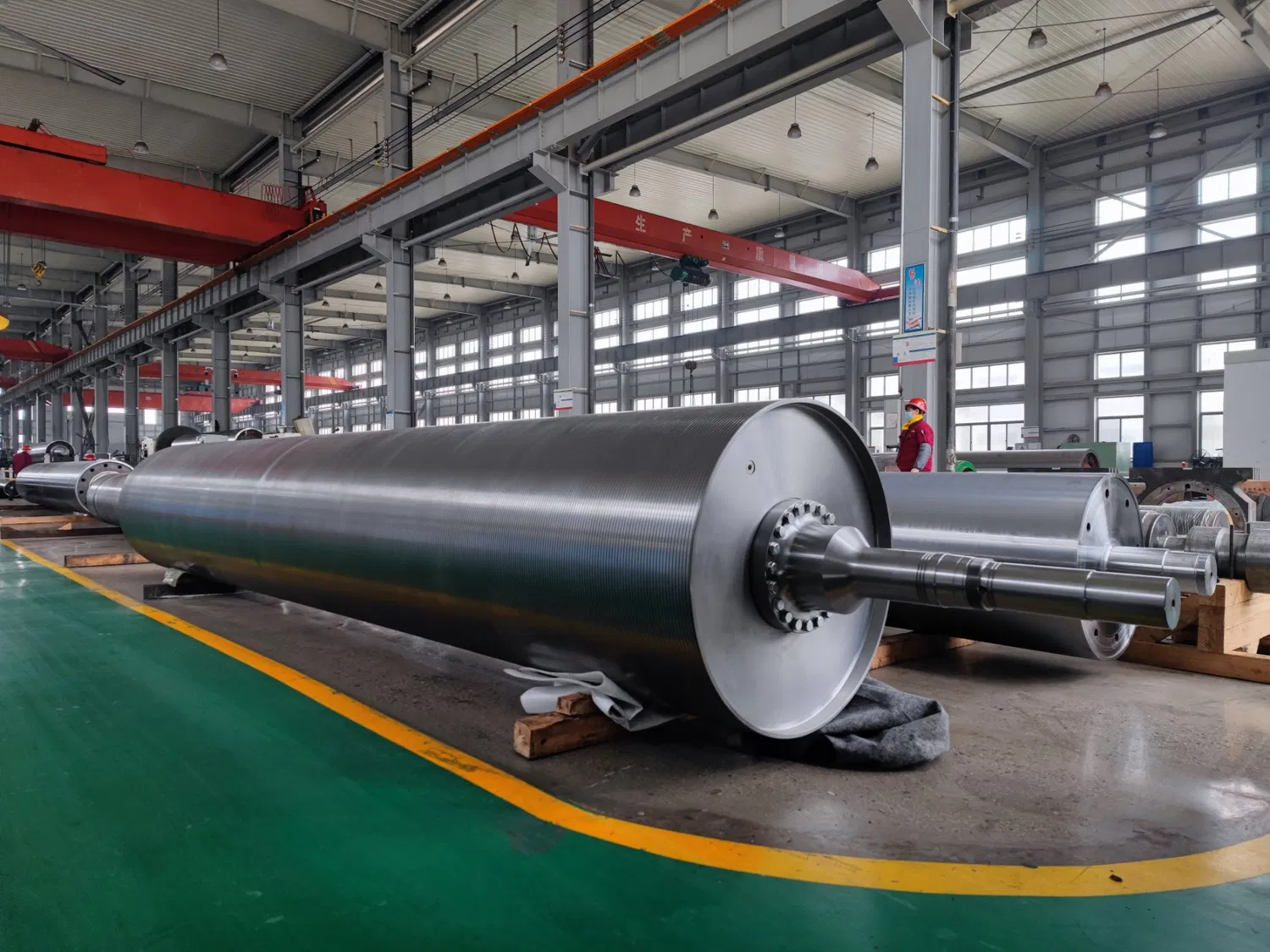

So, what exactly is dynamic balancing? In a nutshell, it's the process of ensuring that the weight distribution of a rotating object – in this case, paper machine rolls – is even. This reduces vibrations, which can cause damage to the machine and affect product quality. It's worth noting that dynamic balancing should be carried out regularly to account for normal wear and tear.

Common Causes of Unbalanced Rolls

There are several reasons why your paper machine rolls might become unbalanced. These include:

- Manufacturing defects

- Damage from misuse or accidents

- Wear and tear from regular use

Impact of Unbalanced Rolls

Unbalanced rolls can lead to increased energy consumption, premature wear of machine components, and reduced product quality. Interestingly enough, even a small imbalance can result in significant vibrations at high speeds, leading to costly downtime and maintenance.

Dynamic Balancing Techniques

There are various dynamic balancing techniques used for high-speed paper machine rolls. Here are some of the most effective ones:

1. Single-Plane Balancing

This technique is typically used when the roll's weight is evenly distributed around its axis. Here's how it works: We add or remove weights from the roll to counterbalance any imbalance. As it turns out, this method is quite effective for low-speed applications.

2. Two-Plane Balancing

For high-speed paper machines, two-plane balancing is often necessary. This method involves balancing both the static and couple weights of the roll. In my experience, this approach significantly reduces vibrations and improves machine performance.

How Our Company Can Help

We specialize in providing dynamic balancing solutions for high-speed paper machines. Our team of experts uses state-of-the-art equipment to accurately measure and correct imbalances, ensuring optimal performance and reducing maintenance costs. If you're interested in learning more about our services, please visit our official website: https://www.er88p.cn

Frequently Asked Questions

Here are answers to some common questions about dynamic balancing:

- How often should I balance my paper machine rolls? This depends on factors such as the roll's speed, load, and operating environment. However, many experts recommend balancing rolls annually or whenever significant vibrations are detected.

- Can unbalanced rolls damage other parts of the machine? Yes, they can. Unbalanced rolls can cause excessive wear on bearings, seals, and other components, leading to costly repairs and downtime.

Conclusion

Dynamic balancing is an essential aspect of maintaining high-speed paper machines. By ensuring that your rolls are properly balanced, you can improve machine performance, reduce maintenance costs, and enhance product quality. If you haven't already, consider incorporating regular dynamic balancing into your maintenance routine. Your paper machine – and your bottom line – will thank you.