For more detailed information, please visit our official website: https://www.er88p.cn

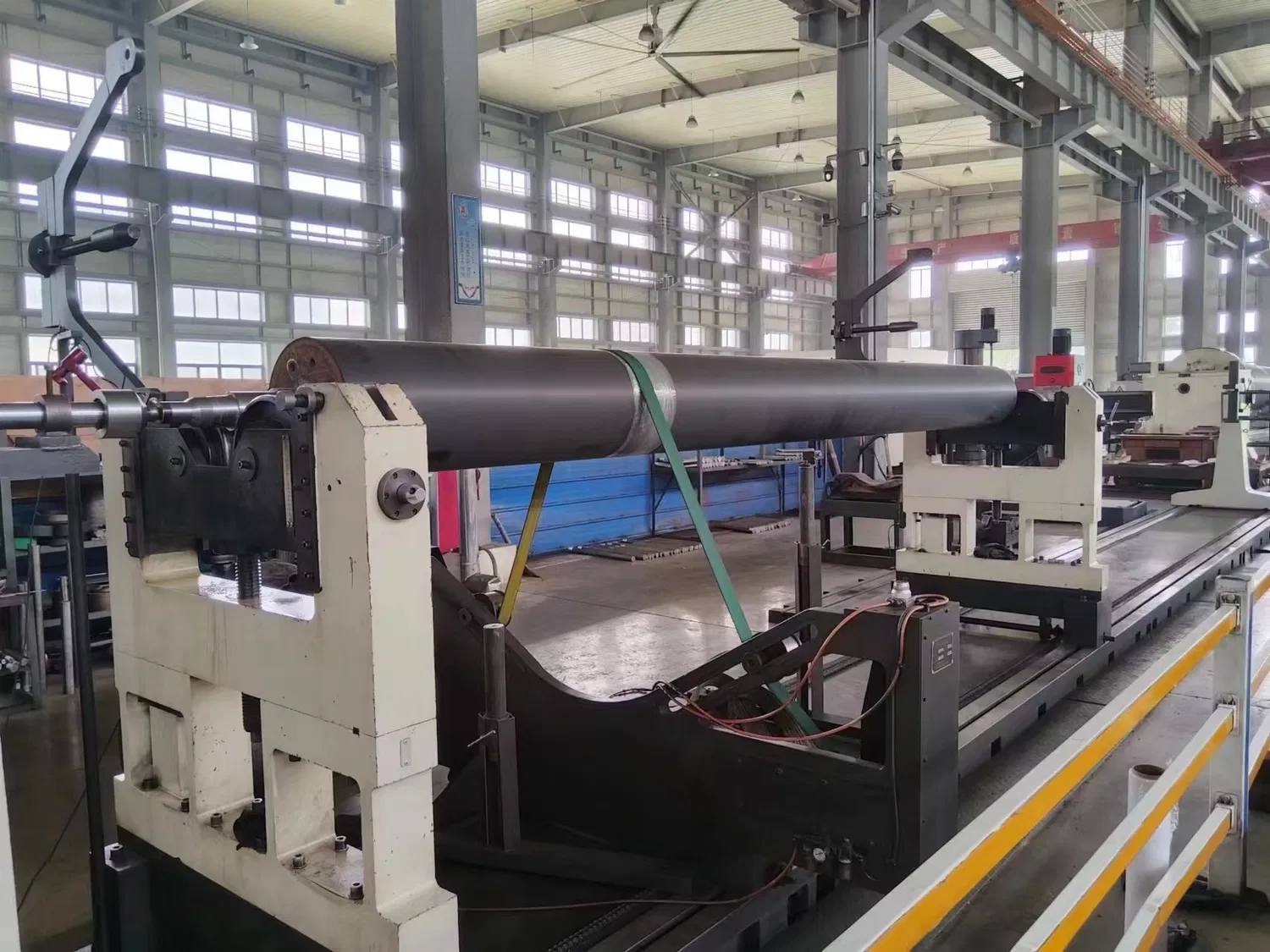

The core of efficient and high-quality paper production lies, more often than not, in components that often go unnoticed: the rollers. Precision-engineered rollers are not simply cylindrical objects; they are sophisticated pieces of machinery designed to exacting specifications to ensure uniform pressure, consistent speed, and optimal contact with the paper web. When these rollers are manufactured and maintained correctly, the impact on paper quality and waste reduction is substantial. Think about it – every imperfection, every slight variation in diameter, hardness, or surface finish, can translate directly into defects in the final product. This can lead to increased waste, higher operating costs, and ultimately, decreased profitability. Therefore, understanding the nuances of roller design, materials, and maintenance is paramount for any paper mill striving for excellence. Have you ever wondered why some paper mills consistently produce higher-quality paper with less waste than others? The answer often resides in their commitment to precision-engineered rollers.

The benefits of using precision-engineered rollers are multifaceted. Firstly, they contribute significantly to the uniformity of paper thickness and density. Variations in these parameters can lead to problems with printing, writing, and even the structural integrity of the paper itself. Precision rollers, manufactured to incredibly tight tolerances, minimize these variations. Secondly, they play a crucial role in the smooth and consistent movement of the paper web through the production process. This reduces the likelihood of tears, breaks, and other disruptions that can lead to downtime and wasted materials. In my experience, the initial investment in high-quality, precision-engineered rollers pays for itself many times over through reduced waste, increased productivity, and improved product quality. It's worth noting that the type of paper being produced also significantly impacts the choice of roller materials and design. Newsprint, for example, requires different roller characteristics than high-gloss coated paper.

The selection of materials for precision-engineered rollers is a critical consideration. Different materials offer varying degrees of hardness, elasticity, and resistance to wear, chemicals, and heat. Common materials include various grades of rubber, polyurethane, and steel, each chosen for its specific properties and suitability for the intended application. For instance, rollers used in coating applications might require a highly chemical-resistant material, while those used in calendaring might benefit from a very hard, smooth surface. To be honest, the expertise of the roller manufacturer in material selection is invaluable. They can provide guidance on the best materials for a specific application, taking into account factors such as the type of paper being produced, the operating temperature, and the chemical environment. This proactive approach to material selection can extend the lifespan of the rollers, reduce maintenance requirements, and further minimize waste.

Proper maintenance and care of precision-engineered rollers are just as important as their initial design and manufacture. Regular cleaning, inspection, and resurfacing are essential to maintain their optimal performance. Even the slightest accumulation of dirt or debris on the roller surface can lead to imperfections in the paper. Similarly, wear and tear over time can degrade the roller's surface finish and dimensional accuracy. I've found that implementing a proactive maintenance schedule, including regular inspections and preventative maintenance, significantly extends the lifespan of the rollers and reduces the risk of costly breakdowns. Resurfacing, which involves grinding or polishing the roller surface to restore its original finish, is another important aspect of roller maintenance. This can correct minor imperfections and restore the roller to its optimal operating condition.

Beyond the immediate benefits of improved paper quality and reduced waste, precision-engineered rollers also contribute to greater overall efficiency in the paper production process. Consistent roller performance translates to more predictable production rates, reduced downtime, and lower energy consumption. For example, rollers with a smooth, uniform surface require less force to move the paper web through the machine, resulting in lower energy consumption. Moreover, the use of high-quality rollers reduces the need for frequent adjustments to the machine settings, further improving efficiency and reducing the risk of errors. In my experience, investing in precision-engineered rollers is not just about improving the quality of the paper; it's about optimizing the entire production process for greater efficiency and profitability.

Consider the impact of roller surface finish on paper quality. A rough or uneven surface can imprint imperfections onto the paper, leading to a lower-quality product. On the other hand, a perfectly smooth and uniform surface ensures consistent contact with the paper web, resulting in a smoother, more uniform finish. Similarly, the hardness of the roller material plays a crucial role in determining the degree of compression applied to the paper. Too much compression can damage the fibers and weaken the paper, while too little compression can result in a loose, porous structure. Precision engineering allows for precise control over these parameters, ensuring that the rollers are perfectly matched to the specific requirements of the paper being produced. Many experts agree that the surface finish and hardness are two of the most critical factors influencing paper quality.

Frankly speaking, our company understands the critical role that precision-engineered rollers play in the paper production industry. We offer a comprehensive range of rollers designed to meet the diverse needs of our customers. Our rollers are manufactured using the highest quality materials and the latest manufacturing techniques to ensure exceptional performance and durability. We also provide a full range of maintenance and repair services to help our customers keep their rollers in optimal condition. Our team of experienced engineers can work with you to select the right rollers for your specific application and to develop a customized maintenance plan to maximize their lifespan and performance. We are committed to providing our customers with the best possible products and services to help them improve their paper quality, reduce waste, and optimize their operations. We believe that investing in our products is investing in the future of your paper mill.

Why is this approach so effective? Because it addresses the root cause of many paper production problems. By ensuring that the rollers are perfectly engineered and maintained, we eliminate a major source of variability and inconsistency in the process. This leads to a more stable and predictable production environment, allowing our customers to achieve consistently high-quality paper with minimal waste. Ultimately, it's about providing our customers with the tools they need to succeed in a competitive market. Our commitment to quality, innovation, and customer service sets us apart from the competition. We are proud to be a trusted partner to paper mills around the world. Through our products, services, and expertise, we empower them to produce high-quality paper efficiently and sustainably.

In conclusion, precision-engineered rollers are an indispensable component of modern paper production, directly impacting both paper quality and waste reduction. The investment in high-quality rollers, coupled with a proactive maintenance program, yields significant returns in terms of improved product consistency, reduced downtime, and lower operating costs. By focusing on precision and attention to detail, paper mills can unlock significant improvements in efficiency and profitability. The subtle art of paper production truly hinges on these seemingly simple, yet incredibly complex, components. The benefits derived from prioritizing precision-engineered rollers are substantial and contribute directly to a more sustainable and profitable operation. This commitment to excellence will undoubtedly separate the leaders from the followers in the ever-evolving paper industry.