Stone rolls play a crucial role in various industries, from construction and mining to food processing and paper production. Choosing the right material for these rolls is paramount for efficiency, durability, and ultimately, the success of the operation. Granite has long been a favored material, but what makes it stand out, and how does it compare to other options? Let's delve into the world of stone rolls and uncover the key properties that make granite a top contender.

Understanding the Demands of Stone Rolls

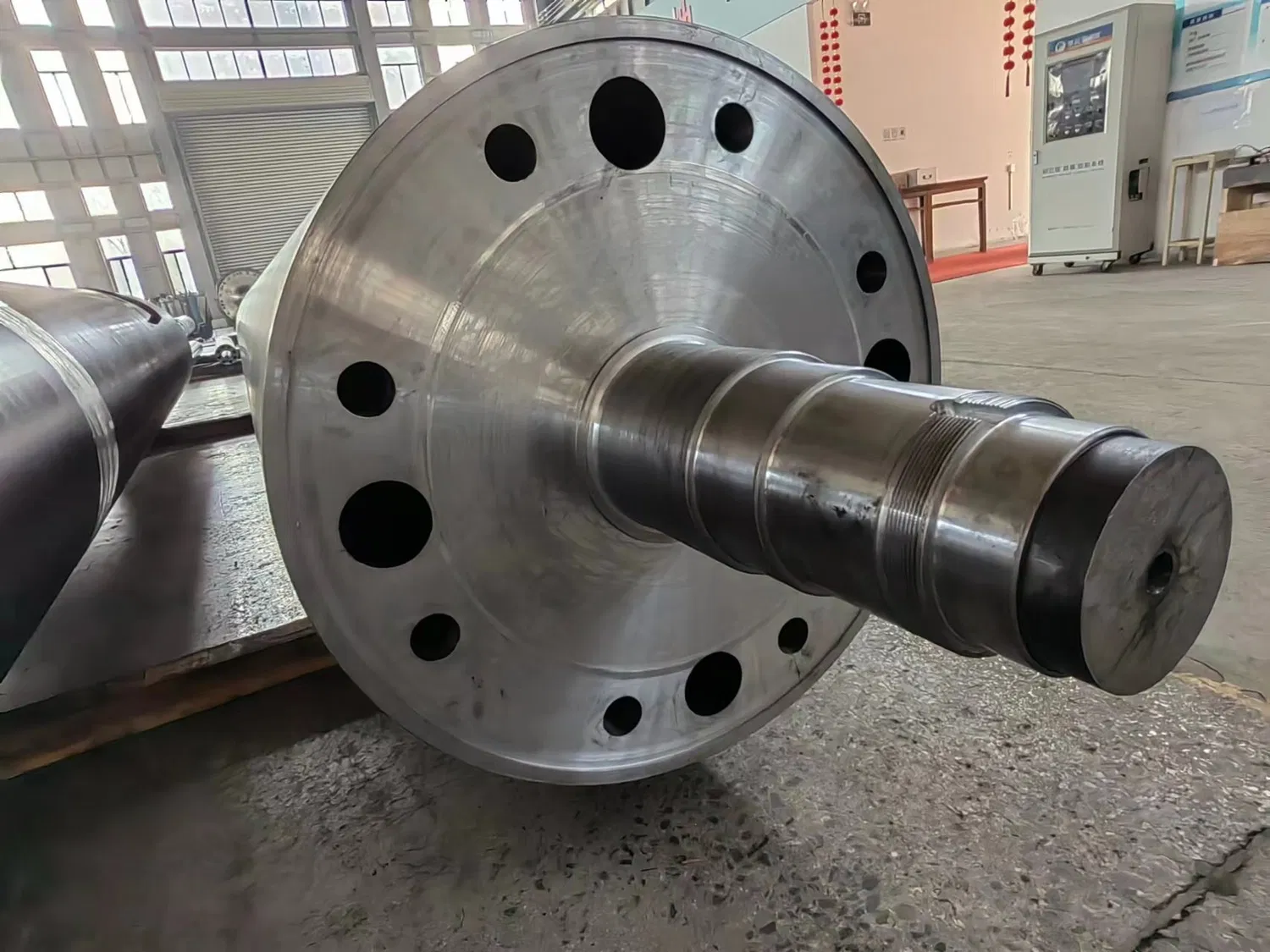

Stone rolls are subjected to significant stresses and strains, often operating under high pressure and temperature fluctuations. They need to resist wear and tear, maintain their dimensional stability, and deliver consistent performance. The material chosen needs to withstand abrasion from the materials being processed, as well as potential impacts and chemical exposure. Imagine the constant friction and pressure exerted on a roll crushing rock in a mining operation – the material needs to be tough!

Furthermore, the specific application dictates the ideal material properties. A roll used for delicate food processing will have different requirements than one used for grinding ore. Factors like desired surface finish, throughput, and material compatibility all influence the decision-making process. So, what makes granite so suitable for these demanding applications?

Granite: A Deep Dive into its Strengths

Granite's inherent hardness and durability make it an excellent choice for stone rolls. Its crystalline structure provides exceptional resistance to abrasion and wear, ensuring a long lifespan even under heavy use. This translates directly into lower maintenance costs and reduced downtime, crucial factors in any industrial setting.

Moreover, granite’s natural resistance to thermal shock is a significant advantage, especially in applications involving temperature variations. This stability prevents cracking and warping, maintaining the roll's integrity and performance over time. Think about a roll used in a high-temperature kiln – the ability to withstand rapid temperature changes is essential.

Exploring Alternatives: Steel, Marble, and Composites

While granite holds a prominent position, other materials also find their place in the world of stone rolls. Steel, known for its strength and toughness, can be a viable option, especially in applications requiring high impact resistance. However, steel can be susceptible to corrosion and may require specific coatings or treatments to enhance its longevity.

Marble, another natural stone, offers a different set of characteristics. While generally softer than granite, marble’s unique properties make it suitable for specialized applications, such as the processing of delicate materials where a less abrasive surface is required. Think of polishing delicate stones or creating intricate designs – marble’s gentler touch might be preferred.

Composite materials, engineered combinations of various substances, offer a range of customizable properties. By tailoring the composition, manufacturers can create rolls with specific characteristics like enhanced wear resistance, chemical inertness, or specific surface textures. However, composite rolls can be more expensive than traditional materials like granite or steel.

Comparing Granite to the Competition

So, how does granite stack up against these alternatives? While steel boasts high strength, granite often offers superior wear resistance and thermal stability. Marble, while gentler, may not be suitable for applications requiring high durability. Composites offer customization, but often at a higher cost. Granite strikes a balance between performance, longevity, and cost-effectiveness, making it a popular choice across various industries.

Practical Applications and Examples

Granite rolls are utilized in a wide array of applications, from crushing ore in mining operations to grinding grains in food processing. Their durability and resistance to wear make them ideal for handling abrasive materials, while their thermal stability ensures consistent performance even under fluctuating temperatures. Consider a paper mill where the rolls are constantly subjected to friction and moisture – granite’s robustness makes it a reliable choice.

Choosing the Right Material: Key Considerations

Selecting the appropriate material for a stone roll requires careful consideration of several factors. The specific application, the material being processed, the desired throughput, and the budget all play a role in the decision-making process. What kind of surface finish is required? How crucial is wear resistance? Answering these questions helps narrow down the options and identify the best fit.

Making an Informed Decision

Ultimately, the choice between granite and other materials depends on the specific needs of the application. Understanding the strengths and weaknesses of each material, along with the demands of the process, is essential for making an informed decision. Consider consulting with industry experts or material suppliers to gain valuable insights and ensure the optimal choice for your specific requirements.

The Enduring Appeal of Granite

Granite continues to be a leading material for stone rolls due to its impressive combination of hardness, durability, and thermal stability. While alternatives like steel, marble, and composites offer unique advantages in specific niches, granite’s versatility and cost-effectiveness solidify its position as a top contender in a variety of industrial applications. Have you considered the benefits of granite for your stone roll needs?