The world of stone processing relies heavily on the robust performance of stone rolls. These crucial components, responsible for crushing, grinding, and shaping various stone materials, demand meticulous design and manufacturing. Precision engineering lies at the heart of creating effective and durable stone roll solutions, impacting everything from the initial design phase to the ongoing maintenance procedures. This article delves into the multifaceted role precision engineering plays in optimizing stone roll solutions across diverse industrial applications.

The Importance of Precise Design

The design phase sets the stage for the entire lifespan of a stone roll. Engineers must consider factors such as the intended application, the type of stone being processed, the desired output, and the operating environment. Precision engineering ensures that the roll's dimensions, material composition, and surface profile are precisely calculated and optimized for maximum efficiency and longevity. This includes careful selection of materials resistant to abrasion and impact, as well as the precise configuration of the roll's surface to achieve the desired crushing or grinding action. A slight deviation in any of these parameters can significantly impact the roll's performance and lifespan.

Precision Manufacturing: From Raw Material to Finished Product

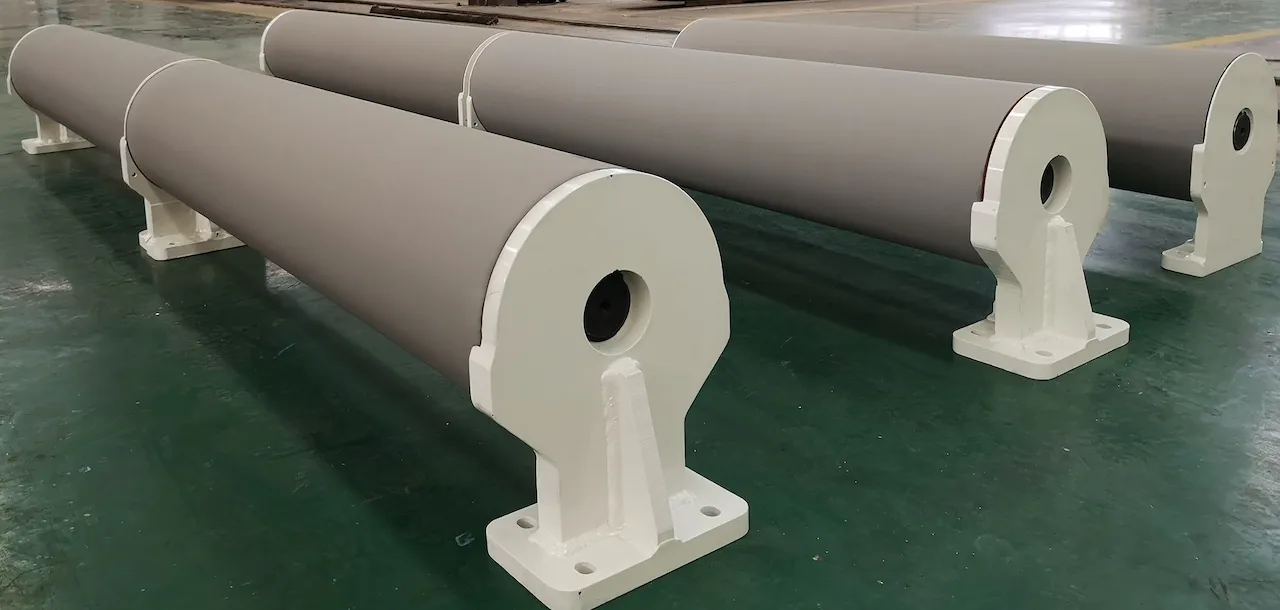

Translating the meticulous design into a tangible product requires equally precise manufacturing processes. This involves the use of advanced machining techniques, such as CNC milling and grinding, to achieve tight tolerances and surface finishes. Precision engineering dictates the selection of appropriate tooling, cutting speeds, and feed rates to ensure the final product conforms precisely to the design specifications. The manufacturing process also incorporates rigorous quality control measures at each stage, from raw material inspection to final product testing, to guarantee the highest standards of quality and performance.

The Role of Roll Grinding and Maintenance

Even with the most precise design and manufacturing, stone rolls are subject to wear and tear over time. Regular maintenance, including roll grinding, is essential to maintain optimal performance and extend the lifespan of these critical components. Precision engineering plays a crucial role in this process by providing the tools and techniques necessary for accurate resurfacing and re-profiling of worn rolls. This ensures the rolls continue to operate efficiently and produce consistent results throughout their service life. How frequently should roll grinding be performed? This depends on factors such as the hardness of the material being processed and the intensity of the operation.

Material Selection and its Impact on Performance

Choosing the right material for a stone roll is paramount. Different stones require different material properties to ensure efficient processing and prevent premature wear. Precision engineering guides the selection process, taking into account factors such as hardness, abrasion resistance, impact strength, and thermal stability. For example, processing extremely hard stones might necessitate the use of specialized alloys or ceramics, while softer stones might be effectively processed with more conventional steel alloys. Understanding the nuances of each material and its interaction with the target stone is crucial for optimizing performance and longevity.

Advanced Technologies in Stone Roll Engineering

The field of stone roll engineering is constantly evolving, with new technologies and techniques emerging to enhance performance and efficiency. Innovations such as laser cladding and thermal spraying allow for the application of specialized coatings to enhance wear resistance and improve the roll's interaction with the processed material. Similarly, advancements in CNC machining and automation enable more precise and efficient manufacturing processes. These advancements are driven by the principles of precision engineering, constantly pushing the boundaries of what's possible in stone processing.

Optimizing Performance through Dynamic Balancing

Dynamic balancing is a critical aspect of precision engineering in stone roll solutions. A properly balanced roll minimizes vibrations, reduces wear on bearings and other components, and improves the overall efficiency of the system. This process involves precisely adjusting the weight distribution of the roll to ensure smooth and stable rotation at high speeds. The precision involved in this process is crucial for maintaining the integrity of the equipment and ensuring optimal performance over extended periods.

Applications of Precision Engineered Stone Rolls

Precision engineered stone rolls find applications in a wide range of industries, from mining and quarrying to construction and agriculture. They are used for crushing and grinding various materials, including limestone, granite, basalt, and other types of rock. The specific design and configuration of the roll are tailored to the specific application, ensuring optimal performance in each scenario. For instance, the rolls used in cement production differ significantly from those used in aggregate processing, highlighting the versatility and adaptability of precision-engineered stone roll solutions.

The Future of Precision Engineering in Stone Roll Solutions

As technology continues to advance, we can expect to see further innovations in the design, manufacturing, and maintenance of stone rolls. These advancements will likely focus on improving efficiency, reducing wear, and extending the lifespan of these critical components. What role will artificial intelligence and machine learning play in the future of stone roll engineering? These technologies have the potential to further optimize design parameters, predict maintenance needs, and enhance the overall performance of stone roll solutions.

Conclusion: The Cornerstone of Efficient Stone Processing

Precision engineering forms the bedrock of efficient and reliable stone roll solutions. From the initial design phase to the ongoing maintenance procedures, precision is paramount in ensuring optimal performance, longevity, and cost-effectiveness. The meticulous attention to detail and the application of advanced technologies ensure that stone rolls continue to meet the demanding requirements of various industries, playing a crucial role in shaping our built environment and supporting essential industrial processes.