The papermaking industry constantly strives for enhanced efficiency, improved paper quality, and reduced operational costs. A critical component contributing to these goals is the stone roll, playing a vital role in the calendering process. Advancements in stone roll technology are continuously evolving, pushing the boundaries of paper production capabilities.

Traditional stone rolls, typically composed of granite or other hard stones, have long been valued for their durability and ability to impart a smooth finish to paper. However, their inherent limitations, including sensitivity to thermal shock and difficulty in achieving precise nip pressure profiles, have spurred the development of innovative solutions.

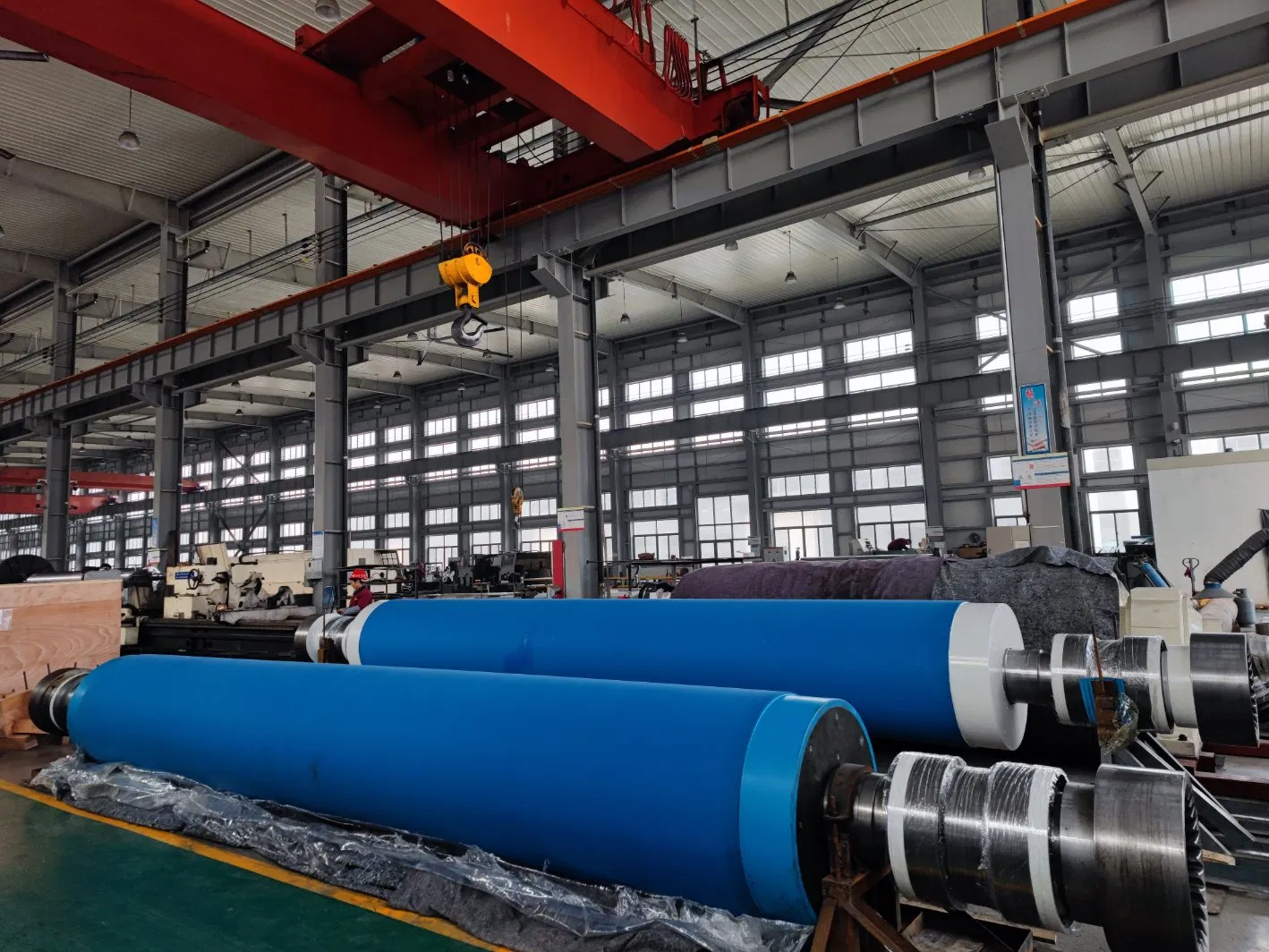

One significant advancement is the development of composite stone rolls. These rolls combine the hardness and wear resistance of traditional stone with the flexibility and thermal stability of composite materials. This hybrid approach offers a superior solution, minimizing issues related to cracking and warping while allowing for greater control over the nip pressure profile.

Another notable development is the integration of advanced control systems into stone roll operation. These systems utilize sophisticated sensors and actuators to monitor and adjust nip pressure in real time, ensuring consistent paper quality and minimizing variations across the web. Think about the implications for paper uniformity – it's a game-changer!

Furthermore, advancements in grinding and polishing techniques have significantly improved the surface finish achievable with stone rolls. Diamond grinding and polishing, for example, can produce exceptionally smooth and precise roll surfaces, resulting in enhanced paper gloss and printability. This precision contributes to a higher quality end product and reduces waste due to surface imperfections.

The introduction of temperature control systems within stone rolls also represents a substantial advancement. Controlling the roll temperature allows for finer tuning of the calendering process, optimizing paper properties such as smoothness, caliper, and density. This level of control allows paper manufacturers to tailor the final product to specific customer requirements.

Improved bearing designs and lubrication systems have also contributed to enhanced stone roll performance. These advancements minimize friction and wear, extending the operational lifespan of the rolls and reducing maintenance requirements. This directly translates to cost savings and increased uptime for paper mills.

Moreover, predictive maintenance technologies are being increasingly integrated into stone roll management systems. By analyzing operational data and identifying potential issues before they escalate, these technologies help prevent costly downtime and optimize maintenance schedules. Imagine the benefits of predicting and preventing a roll failure before it impacts production!

The drive towards sustainability is also influencing advancements in stone roll technology. Researchers are exploring the use of eco-friendly materials and manufacturing processes to minimize the environmental footprint of stone roll production and operation. This commitment to sustainability is crucial for the long-term health of the paper industry.

Considering these advancements, what role do you see stone roll technology playing in the future of papermaking? How might these innovations further enhance paper quality and production efficiency?

In conclusion, the advancements in stone roll technology are revolutionizing the papermaking industry. From composite materials and advanced control systems to improved grinding techniques and sustainable practices, these innovations are driving improvements in paper quality, production efficiency, and environmental responsibility. The ongoing development in this field promises further advancements that will continue to shape the future of paper production.