The paper industry, a cornerstone of modern communication and packaging, relies heavily on precision engineering and carefully controlled processes. Within this complex web of machinery and technology, stone rolls stand out as critical components, playing an indispensable role in achieving the desired quality and efficiency in paper production. Their significance is deeply intertwined with the very fabric of the paper we use every day.

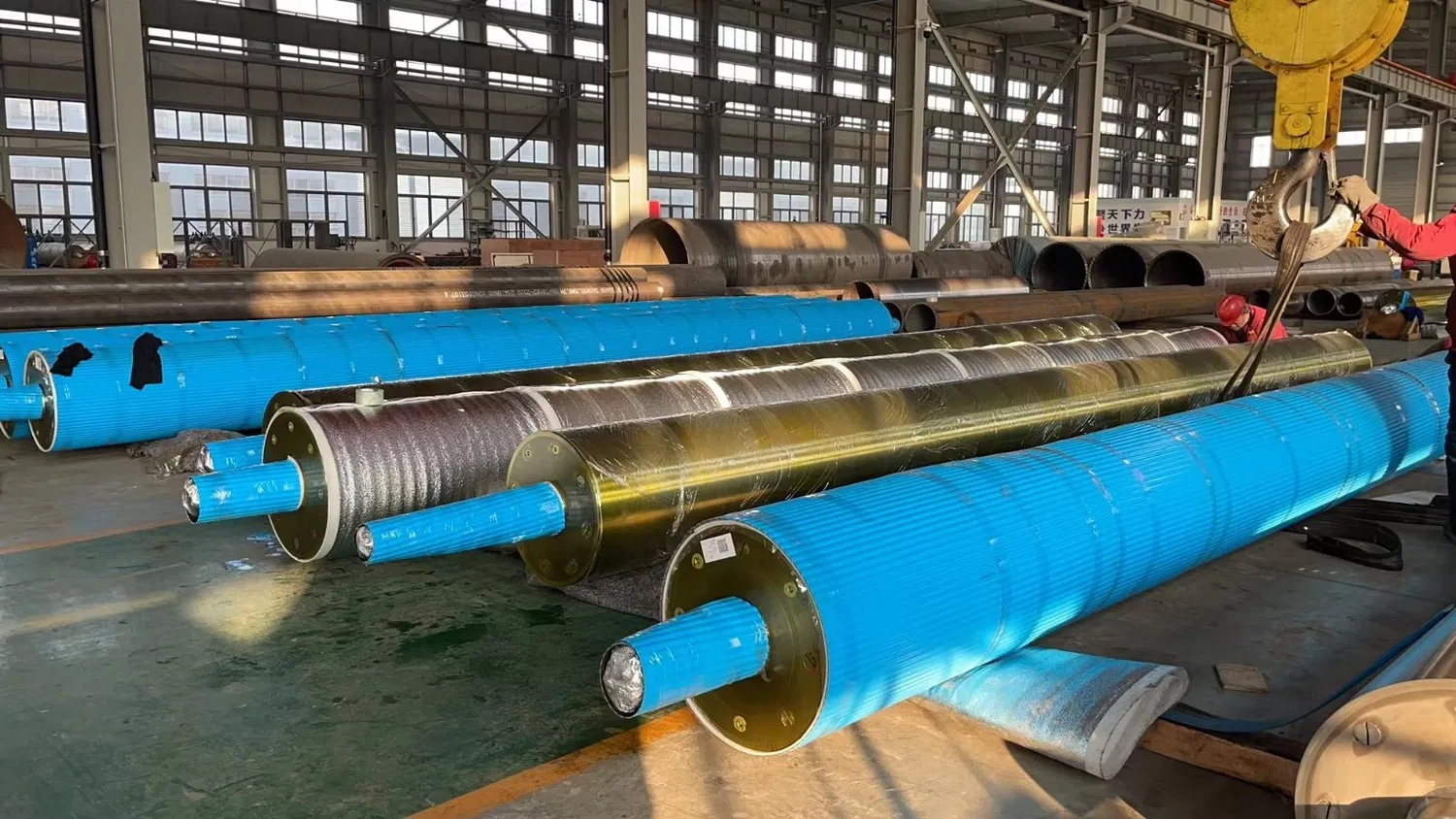

Stone rolls, typically crafted from granite or other hard, durable stones, are employed at various stages in the papermaking process. Their primary function is to impart specific surface characteristics to the paper web, influencing properties such as smoothness, gloss, and absorbency. These properties are not mere aesthetic considerations; they dictate the paper's suitability for its intended application, whether it's high-quality printing, absorbent tissue paper, or robust packaging material.

One of the key advantages of using stone rolls lies in their unique ability to calibrate and control the paper's caliper (thickness) and density. As the paper web passes through the nip between a stone roll and a metallic roll, the pressure applied influences the final sheet properties. This precision control is vital for ensuring uniformity across the entire roll of paper, minimizing variations that could impact printability or other functional aspects.

The exceptional hardness and temperature stability of stone rolls also contribute to their effectiveness. Unlike metallic rolls, which can expand and contract with temperature fluctuations, stone rolls maintain their dimensional stability, ensuring consistent performance regardless of operating conditions. This stability translates into higher quality paper and reduced downtime due to adjustments or recalibration.

Consider the production of glossy magazine paper. The high-gloss finish, so crucial for showcasing vibrant images, is often achieved through calendering – a process involving passing the paper web through a series of rolls, including stone rolls. The precise pressure and smooth surface of the stone rolls impart the desired gloss, transforming a rough paper web into a sleek, polished surface ready for printing.

In the production of tissue paper, stone rolls play a different yet equally important role. Here, the goal is not gloss but softness and absorbency. The stone rolls are used to create a textured, creped surface that enhances the paper's ability to absorb liquids and feel soft against the skin. Imagine the difference between a coarse, scratchy tissue and a soft, absorbent one – this difference is often a direct result of the application of stone rolls in the manufacturing process.

But the benefits of stone rolls extend beyond simply influencing the paper's surface characteristics. They also contribute to overall production efficiency. Their durability and resistance to wear and tear mean less frequent replacements and reduced maintenance compared to other types of rolls. This translates into cost savings and less downtime, boosting the productivity of the entire papermaking operation.

Furthermore, the use of stone rolls can reduce the reliance on chemical treatments to achieve specific paper properties. This is a growing concern in the industry as there’s increasing pressure to adopt more sustainable practices. By utilizing the inherent properties of stone rolls, papermakers can minimize the use of potentially harmful chemicals, contributing to a more environmentally friendly production process. What are the future implications of this shift towards more sustainable papermaking practices?

The selection of the appropriate stone material for the rolls is crucial and depends on the specific application. Granite is a popular choice due to its hardness and stability, but other stones like marble or basalt might be preferred for certain paper grades. The surface finish of the stone roll is also a critical factor, as it directly impacts the final texture of the paper.

In conclusion, the importance of stone rolls in modern papermaking cannot be overstated. From enhancing sheet quality to boosting production efficiency and promoting sustainability, these seemingly simple components play a vital role. They are integral to the complex process that transforms wood pulp into the countless paper products we rely on daily. So, the next time you pick up a magazine, a tissue, or a piece of packaging, consider the subtle yet significant contribution of stone rolls to its creation. How might future advancements in stone roll technology further revolutionize the papermaking industry?