Introduction to Paper Mill Touch Rolls

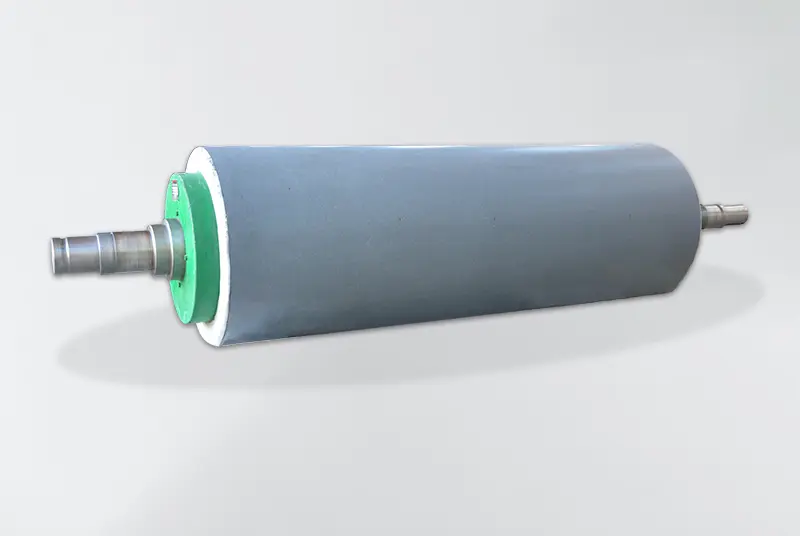

In the intricate world of paper manufacturing, every component of the machinery plays a crucial role in ensuring the quality and efficiency of the final product. Among these components, the touch roll stands out as a vital element in the papermaking process. These rolls, often constructed from 304 stainless steel, are designed to come into direct contact with the paper web during various stages of production, influencing everything from smoothness and texture to moisture content and overall structural integrity. But what exactly makes a touch roll so important, and why is the choice of material, such as 304 stainless steel, so critical? The selection of the appropriate touch roll is paramount to achieving the desired paper quality and ensuring efficient operation of the paper mill.The Importance of 304 Stainless Steel

Why is 304 stainless steel the go-to material for many paper mill touch rolls? The answer lies in its exceptional properties. 304 stainless steel offers excellent corrosion resistance, which is crucial in the harsh chemical environment of a paper mill. It’s also known for its durability and strength, allowing it to withstand the constant pressure and wear of the papermaking process. Furthermore, it's relatively easy to clean and maintain, which is essential for preventing contamination of the paper web. Choosing the right material ensures long-lasting performance and minimal downtime. The use of 304 stainless steel in the **China Paper Mill Spare Part Customized Paper Making 304 Stainless Steel Touch Roll** significantly contributes to the overall lifespan and reliability of the equipment.Key Features and Benefits of Our Customized Touch Rolls

Our customized paper making 304 stainless steel touch rolls offer a range of features designed to optimize paper production. We manufacture to your specific needs. One of the most significant advantages is the ability to tailor the roll's surface finish to achieve the desired paper texture. Whether you need a smooth, glossy finish or a more textured surface, we can create a roll that meets your exact requirements. The precision engineering of these rolls ensures uniform pressure distribution across the paper web, preventing wrinkles, tears, and other defects. Additionally, our touch rolls are designed for easy installation and maintenance, minimizing downtime and maximizing productivity. We understand the critical nature of uptime in the paper industry, and our designs reflect this understanding.Technical Specifications and Performance Parameters

Understanding the technical specifications of a touch roll is crucial for ensuring optimal performance. Parameters such as roll diameter, surface roughness, and dynamic balance are all critical factors. Our touch rolls are engineered to precise tolerances, ensuring smooth and consistent operation. The surface roughness can be customized to achieve specific paper texture requirements. Dynamic balance is carefully controlled to minimize vibration and noise, leading to improved overall machine performance and reduced wear on other components. We also offer a variety of coatings to further enhance the roll's performance, such as anti-stick coatings to prevent paper buildup. Consider the impact of properly specified touch rolls on the efficiency of your entire paper production line.Application Scenarios and Problem Solving

The applications of our customized touch rolls are diverse and span various stages of the papermaking process. They can be used in the wet end of the machine to help remove water from the paper web, in the press section to consolidate the fibers, and in the dryer section to ensure a smooth and even surface. One common problem that touch rolls can help solve is uneven moisture content in the paper web. By carefully controlling the pressure and temperature of the roll, it's possible to achieve a more uniform moisture profile, leading to improved paper quality and reduced waste. Our **China Paper Mill Spare Part Customized Paper Making 304 Stainless Steel Touch Roll** is designed to address these challenges effectively.Quality Standards and Certifications

Quality is at the forefront of our manufacturing process. We adhere to strict quality standards throughout the entire production cycle, from material selection to final inspection. Our 304 stainless steel touch rolls undergo rigorous testing to ensure they meet or exceed industry standards. These tests include dimensional accuracy checks, surface roughness measurements, and dynamic balance testing. Furthermore, we are committed to environmental responsibility and strive to minimize our environmental impact. We are continuously working to improve our processes and reduce waste.Reliability and Durability: The Foundation of Our Touch Rolls

In the demanding environment of a paper mill, reliability and durability are non-negotiable. Our touch rolls are built to last, minimizing downtime and maximizing productivity. The robust construction of our rolls, combined with the corrosion resistance of 304 stainless steel, ensures long-term performance even under harsh conditions. We use advanced manufacturing techniques and high-quality materials to create touch rolls that can withstand the constant pressure and wear of the papermaking process. Regular maintenance and inspections can further extend the lifespan of our touch rolls.Customization Options and Global Supply Capabilities

We understand that every paper mill has unique requirements. That's why we offer a wide range of customization options for our touch rolls. From surface finish and diameter to coatings and materials, we can tailor the roll to your specific needs. Our experienced engineers will work closely with you to understand your requirements and develop a custom solution that optimizes your papermaking process. We also offer global supply capabilities, ensuring that our touch rolls are available to paper mills around the world. Our streamlined logistics and efficient production processes enable us to deliver orders quickly and reliably. In addition to customized solutions, we also offer standard sizes and configurations to meet common needs.Support for Business and Individual Purchases

Whether you're a large paper mill or an individual looking for a specific touch roll solution, we're here to help. We offer flexible order quantities and customization possibilities to meet your needs. Our knowledgeable sales team can provide expert advice and guidance to help you choose the right touch roll for your application. We also offer sample availability, allowing you to evaluate the quality and performance of our rolls before making a large purchase. In addition, we provide comprehensive after-sales support, including installation assistance, maintenance guidance, and troubleshooting. Our goal is to build long-term relationships with our customers by providing exceptional products and services. The versatility of our offerings caters to both large-scale business needs and individual specialized requirements. Our **China Paper Mill Spare Part Customized Paper Making 304 Stainless Steel Touch Roll - Model ER88P** is a popular option.Manufacturing Capabilities and Quality Control

Our state-of-the-art manufacturing facilities are equipped with advanced machinery and technology, allowing us to produce high-quality touch rolls to exacting specifications. Our skilled technicians and engineers have years of experience in the papermaking industry, ensuring that every roll is manufactured to the highest standards. We implement rigorous quality control processes throughout the entire production cycle, from raw material inspection to final product testing. This includes dimensional accuracy checks, surface roughness measurements, dynamic balance testing, and corrosion resistance testing. Our commitment to quality ensures that our touch rolls deliver consistent performance and long-term reliability.Quick Lead Times and Stable Supply

We understand the importance of minimizing downtime in the paper industry. That's why we offer quick lead times and a stable supply of our touch rolls. Our efficient production processes and streamlined logistics enable us to fulfill orders quickly and reliably. We maintain a large inventory of standard sizes and configurations to meet immediate needs. For customized orders, we work closely with our customers to establish realistic lead times and ensure on-time delivery. Our commitment to stable supply and quick lead times helps our customers minimize downtime and maximize productivity.Conclusion

Investing in high-quality, customized touch rolls is a smart decision for any paper mill looking to improve efficiency, reduce waste, and enhance paper quality. Our **China Paper Mill Spare Part Customized Paper Making 304 Stainless Steel Touch Roll** offers a reliable, durable, and customizable solution for a wide range of papermaking applications. From surface finish and diameter to coatings and materials, we can tailor the roll to your specific needs. Our commitment to quality, quick lead times, and global supply capabilities makes us a trusted partner for paper mills around the world. Consider upgrading to our touch rolls for a significant boost in your paper production processes.For more detailed information, please visit our official website: https://www.er88p.cn