The paper industry relies heavily on the precise functionality of its machinery, and at the heart of many paper-making processes lie rolls. These rolls, subjected to immense pressure, heat, and abrasive materials, inevitably wear down over time. That's where roll grinding services come in. Simply put, roll grinding is the process of restoring the original surface and profile of these crucial rolls. But beyond the simple definition, lies a critical maintenance procedure that directly impacts the quality of the paper produced, the efficiency of the paper mill, and ultimately, the profitability of the entire operation. Neglecting this essential service can lead to a cascade of problems, from substandard paper quality to costly downtime and repairs.

The Critical Role of Roll Grinding in Paper Production

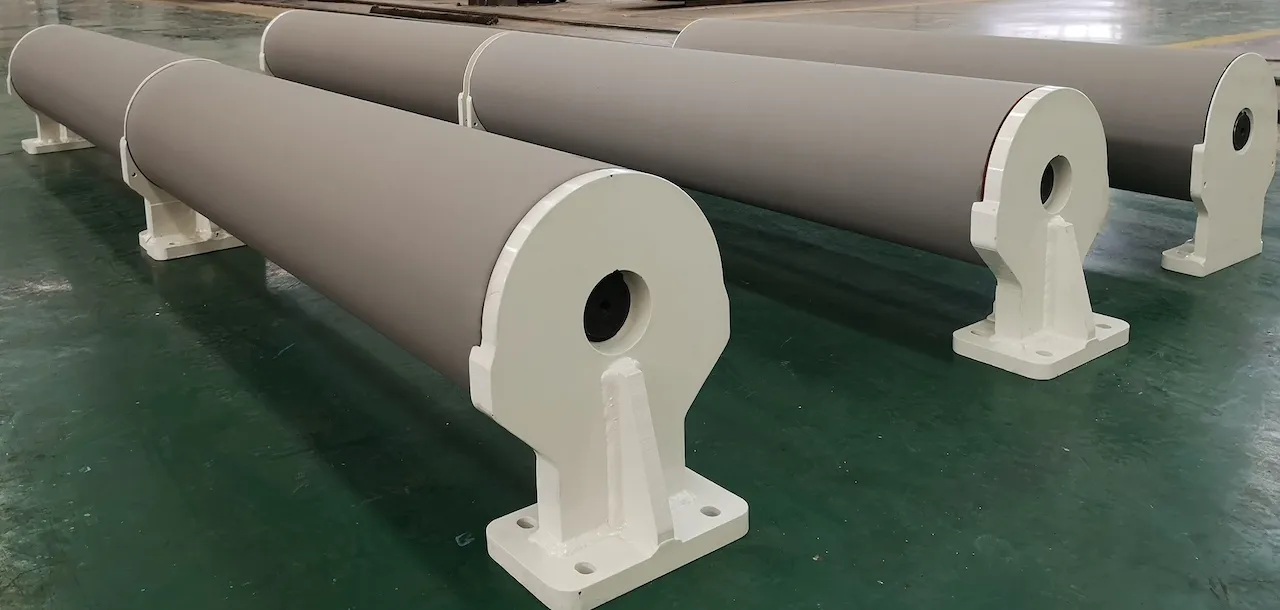

Roll grinding isn't just about making the rolls look new; it's about ensuring they perform optimally. These rolls are responsible for a variety of functions, including pressing, calendaring, and coating the paper web. Each function demands a specific surface profile and finish. Over time, wear and tear can cause these profiles to degrade, leading to uneven pressure distribution, inconsistent coating application, and ultimately, paper with defects. Think of it like this: a worn-out roll is like a slightly bent car tire – it might still work, but it’s definitely not giving you the smooth ride (or in this case, the smooth paper) you expect. Roll grinding restores the precise geometry of the roll, ensuring consistent contact and uniform pressure across the paper web. This translates directly into improved paper quality, reduced waste, and increased production efficiency.

When is Roll Grinding Necessary? Identifying the Warning Signs

Knowing when to schedule roll grinding is just as important as understanding the process itself. Several telltale signs indicate that your rolls are in need of attention. Keep an eye out for these red flags: changes in paper quality, such as uneven thickness, variations in smoothness, or inconsistent coating; vibrations or unusual noises emanating from the machinery; visible wear and tear on the roll surface, including scratches, grooves, or pitting; and inconsistent nip profiles. Furthermore, scheduled preventative maintenance is key. Regularly inspecting your rolls and establishing a proactive grinding schedule can prevent minor issues from escalating into major problems. Speaking from experience, it's far more cost-effective to address wear and tear early on than to wait until a roll fails completely, causing significant downtime and potentially damaging other components of the machinery.

Why Choose Professional Roll Grinding Services?

While it might be tempting to attempt roll grinding in-house, utilizing professional roll grinding services offers several distinct advantages. These specialized service providers possess the necessary expertise, equipment, and technology to perform the job accurately and efficiently. They use sophisticated grinding machines that are capable of achieving extremely tight tolerances, ensuring that the rolls are restored to their original specifications. Furthermore, they have the knowledge and experience to diagnose and address any underlying issues that may be contributing to the wear and tear on the rolls. This comprehensive approach helps to extend the lifespan of the rolls and prevent future problems. In addition, professional services can often provide on-site grinding, minimizing downtime and transportation costs.

The Impact of Roll Grinding on Paper Quality and Consistency

Frankly, the impact of roll grinding on paper quality is undeniable. By restoring the correct profile and surface finish, roll grinding ensures uniform pressure distribution across the paper web. This, in turn, leads to more consistent paper thickness, smoothness, and density. It also improves the adhesion of coatings, resulting in a more uniform and durable finish. Interestingly, properly ground rolls can even improve the printability of the paper, making it easier to achieve sharp, clear images and text. What happens when you neglect roll grinding? You risk producing paper with inconsistencies that can lead to customer complaints, rejected shipments, and ultimately, damage to your company's reputation. Maintaining roll integrity is thus an investment in the consistency and reputation of your product.

Efficiency Gains Through Regular Roll Grinding

Beyond paper quality, regular roll grinding contributes significantly to the overall efficiency of your paper mill. Worn rolls require more energy to operate, putting strain on the machinery and increasing the risk of breakdowns. Grinding the rolls allows them to operate more smoothly and efficiently, reducing energy consumption and minimizing the risk of unexpected downtime. Moreover, properly ground rolls reduce the amount of waste generated during the paper-making process. Consistent paper thickness and coating application translate into fewer defects and less scrap. This not only saves money on raw materials but also reduces the environmental impact of the operation. Ultimately, investing in regular roll grinding is an investment in the long-term sustainability of your paper mill.

Challenges and Considerations in Roll Grinding

Of course, roll grinding isn’t without its challenges. Selecting the right roll grinding service provider is paramount. You need a company with a proven track record, the necessary equipment, and the expertise to handle your specific type of rolls. Also, consider the downtime required for grinding. While on-site grinding can minimize disruption, it’s still necessary to factor in the time required for the procedure when planning production schedules. Furthermore, the cost of roll grinding can vary depending on the size and complexity of the rolls, as well as the extent of the damage. However, it's important to view roll grinding as an investment rather than an expense. The benefits in terms of improved paper quality, increased efficiency, and reduced downtime far outweigh the initial cost. According to my experience, carefully planning and executing the roll grinding process is crucial for maximizing its benefits and minimizing any potential disruptions.

Real-World Examples of Roll Grinding's Impact

To illustrate the importance of roll grinding, let's consider a few real-world examples. We worked with a corrugated paper manufacturer who was experiencing frequent paper breaks and inconsistent thickness. After analyzing the rolls, we found significant wear and tear on the calendaring rolls. After roll grinding, the paper breaks decreased by 40% and the thickness variation was dramatically reduced. Consider another case: a specialty paper mill that produces coated paper experienced streaking issues due to uneven coating application. Addressing this, roll grinding revealed uneven wear on the coating applicator rolls. Following the grinding, coating was applied more consistently, resolving the streaking issues and improving product quality. These examples highlight how roll grinding services directly address common problems faced by paper mills and lead to significant operational improvements.

Extending Roll Life and Reducing Long-Term Costs

Regular roll grinding not only improves paper quality and efficiency but also extends the lifespan of your rolls. By addressing wear and tear early on, you prevent minor issues from escalating into major problems that could require costly repairs or even roll replacement. Think about it: consistently maintaining your rolls is like regularly servicing your car – it helps to prevent breakdowns and keeps it running smoothly for longer. Moreover, roll grinding can be performed multiple times throughout the lifespan of a roll, maximizing its useful life. Ultimately, by investing in regular roll grinding, you can significantly reduce your long-term maintenance costs and ensure the reliable operation of your paper mill. You see, it’s about optimizing the overall economic cycle of your machine components.

Considering the Future: Advances in Roll Grinding Technology

The field of roll grinding is constantly evolving, with new technologies and techniques emerging all the time. For instance, advancements in grinding wheel materials and CNC control systems are allowing for even greater precision and efficiency. Laser scanning technologies are also being used to create detailed 3D models of rolls, enabling more accurate diagnostics and grinding. In addition, there is a growing emphasis on predictive maintenance, using data analytics to identify potential problems before they occur. These advances promise to further improve the quality, efficiency, and cost-effectiveness of roll grinding services, making them an even more valuable asset for paper mills. What are your thoughts on incorporating these technologies into your mill's maintenance strategy? The goal is to anticipate needs and optimize operations proactively.

Conclusion: Investing in the Heart of Your Paper Mill

In conclusion, roll grinding services are an indispensable component of any well-maintained paper mill. As we’ve explored, understanding when and why your paper mill needs them is crucial for ensuring optimal paper quality, maximizing operational efficiency, and minimizing costly downtime. By recognizing the warning signs of roll wear, selecting a qualified service provider, and embracing new technologies, you can ensure that your rolls continue to perform at their best, supporting the smooth and profitable operation of your entire paper mill. Remember, investing in roll grinding is an investment in the heart of your paper mill – the machinery that directly impacts the quality and consistency of your product. Are you ready to ensure the heart of your paper mill keeps beating strong with regular roll grinding services?