The heart of any paper machine lies in its rolls, and selecting the right material for these crucial components is a decision that significantly impacts production efficiency, paper quality, and overall operational costs. When it comes to choosing between stainless steel and cast iron rolls, there's no one-size-fits-all answer. The "better" choice depends heavily on the specific demands of your paper-making process, the type of paper you're producing, and the environment in which the machine operates. Understanding the inherent properties and performance characteristics of each material is essential to making an informed decision that aligns with your unique requirements.

Understanding the Properties of Stainless Steel Rolls

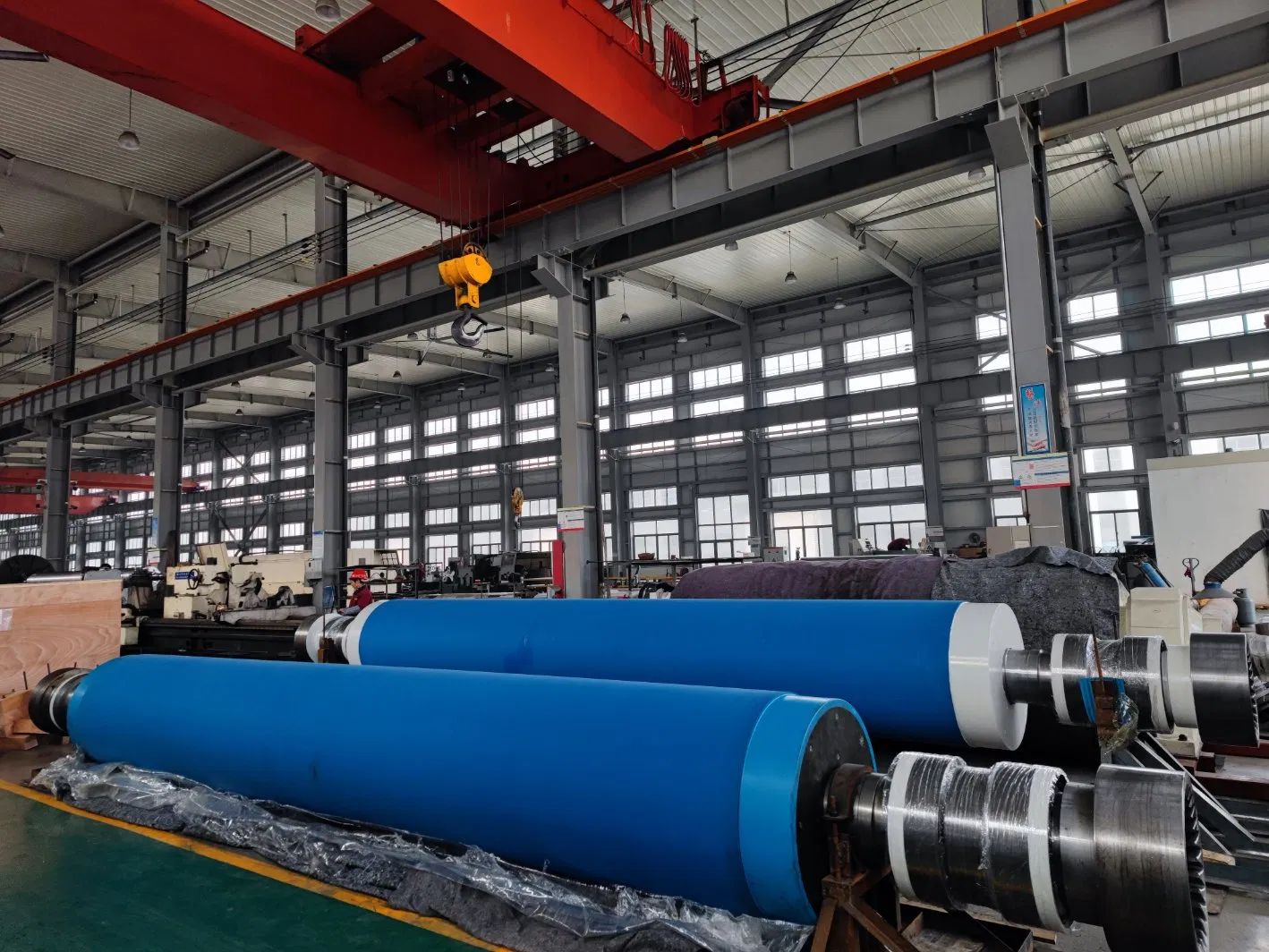

Stainless steel rolls are renowned for their exceptional corrosion resistance, a crucial factor in the harsh, wet environments typical of paper mills. The chromium content in stainless steel forms a passive layer that protects the underlying metal from rust and corrosion, extending the lifespan of the roll and reducing the frequency of replacements. Beyond corrosion resistance, stainless steel offers excellent strength and durability, capable of withstanding the stresses and strains of high-speed paper production. Furthermore, the smooth surface finish achievable with stainless steel contributes to improved paper quality by minimizing defects and ensuring uniform web handling. But honestly, the initial cost of stainless steel can be higher compared to cast iron, a factor that needs careful consideration in your budget.

Exploring the Characteristics of Cast Iron Rolls

Cast iron rolls, on the other hand, present a different set of advantages. Traditionally, cast iron has been a popular choice due to its cost-effectiveness and good thermal conductivity. This thermal conductivity allows for efficient heat transfer, which can be beneficial in certain drying and cooling processes within the paper machine. Moreover, cast iron possesses excellent vibration damping properties, which can help reduce noise and improve the overall stability of the machine. However, it’s crucial to understand the limitations of cast iron. Its susceptibility to corrosion, particularly in acidic or alkaline environments, is a significant concern. Unlike stainless steel, cast iron lacks the inherent protective layer, making it prone to rust and degradation over time. This can lead to increased maintenance requirements and a shorter service life, ultimately impacting long-term costs. Are you prepared for the potential maintenance needs associated with cast iron?

Corrosion Resistance: A Critical Comparison

The stark contrast in corrosion resistance is often the deciding factor for many paper mills. The paper-making process involves various chemicals and additives, many of which can be highly corrosive. Stainless steel's superior resistance ensures longevity and reduces the risk of roll failure due to corrosion. Cast iron, without protective coatings or special treatments, is vulnerable to these corrosive agents, leading to pitting, cracking, and eventual structural weakening. While protective coatings can be applied to cast iron, they add to the cost and require regular inspection and maintenance to ensure their integrity. The question then becomes: is the initial cost savings of cast iron worth the potential long-term expenses associated with corrosion-related issues?

Surface Finish and Paper Quality

The surface finish of the roll directly impacts the quality of the paper produced. Stainless steel rolls can be manufactured with extremely smooth and consistent surfaces, minimizing the likelihood of imperfections and ensuring uniform contact with the paper web. This is particularly important for producing high-quality papers with demanding surface requirements. While cast iron rolls can also be ground and polished, achieving the same level of smoothness and consistency as stainless steel can be challenging. Moreover, the porous nature of cast iron can make it more difficult to maintain a pristine surface over time. A rough or uneven roll surface can lead to variations in paper thickness, surface defects, and ultimately, reduced paper quality.

Cost Considerations: Initial Investment vs. Long-Term Expenses

The initial investment is undeniably a key factor in any purchasing decision. Cast iron rolls generally have a lower upfront cost compared to stainless steel rolls. However, it's essential to consider the total cost of ownership, which includes factors such as maintenance, repairs, downtime, and replacement frequency. Stainless steel's superior durability and corrosion resistance often translate to lower long-term expenses, despite the higher initial investment. Cast iron rolls, on the other hand, may require more frequent maintenance, repairs, and eventual replacement due to corrosion and wear. Therefore, a thorough cost-benefit analysis that considers the entire lifecycle of the rolls is crucial for making an informed decision. According to my experience, many overlook the indirect costs associated with downtime and production losses due to roll failures.

Application-Specific Suitability: Where Each Material Excels

The suitability of stainless steel and cast iron rolls also depends on the specific application within the paper machine. For example, in wet-end sections where the rolls are constantly exposed to water and chemicals, stainless steel is almost always the preferred choice. Its corrosion resistance ensures reliable performance and minimizes the risk of contamination. In dry-end sections, where the temperatures are higher and the risk of corrosion is lower, cast iron rolls may be a viable option, particularly if thermal conductivity is a primary concern. However, even in dry-end applications, stainless steel's durability and surface finish advantages often outweigh the cost savings of cast iron. Consider the type of paper you're producing. For high-quality printing papers or specialty papers, stainless steel is often the better choice to ensure optimal surface characteristics.

Practical Examples and Case Studies

Consider a paper mill producing high-quality coated paper. They initially opted for cast iron rolls in their coater section to save on upfront costs. However, they soon encountered issues with corrosion and surface imperfections, leading to frequent downtime and reduced paper quality. After switching to stainless steel rolls, they experienced a significant improvement in both production efficiency and paper quality, despite the higher initial investment. This highlights the importance of considering the long-term benefits of stainless steel in demanding applications. Another example involves a mill producing recycled paper. The recycled pulp often contains abrasive contaminants that can accelerate wear on roll surfaces. Stainless steel, with its superior hardness and wear resistance, proved to be a more durable and cost-effective solution in the long run.

Maintenance Considerations for Longevity

Regardless of the material chosen, proper maintenance is essential for maximizing the lifespan of your paper machine rolls. For stainless steel rolls, regular cleaning and inspection are crucial for preventing the buildup of deposits and identifying any signs of corrosion. Cast iron rolls require even more diligent maintenance, including regular coating inspections, rust removal, and surface reconditioning. In both cases, proper lubrication and alignment are essential for minimizing wear and tear. Neglecting maintenance can significantly shorten the lifespan of your rolls, regardless of the material. It’s worth noting that a well-maintained stainless steel roll can outlast a poorly maintained cast iron roll by a significant margin.

Making the Right Choice for Your Paper Machine

Ultimately, the decision between stainless steel and cast iron rolls hinges on a careful evaluation of your specific needs and priorities. While cast iron offers a lower initial cost, stainless steel provides superior corrosion resistance, durability, and surface finish, leading to lower long-term expenses and improved paper quality in many applications. Consider the type of paper you're producing, the operating environment, and your long-term maintenance capabilities. Honestly, it often boils down to balancing upfront cost savings with long-term performance and reliability. Many professional engineers find that a hybrid approach, utilizing stainless steel in critical areas prone to corrosion and cast iron in less demanding sections, can be a cost-effective strategy.