The couch roll. It’s a critical component in the paper manufacturing process, playing a pivotal role in transferring the newly formed paper web from the forming section to the press section. This transfer, as you might imagine, isn't always smooth sailing. Problems with the couch roll can lead to a cascade of issues, impacting everything from web breaks and moisture profiles to overall runnability and, ultimately, profitability. Let's delve into some of the most frequently encountered challenges and, more importantly, how to tackle them. Truth be told, understanding the nuances of couch roll performance is key to maintaining efficient and high-quality paper production.

Understanding the Couch Roll and its Function

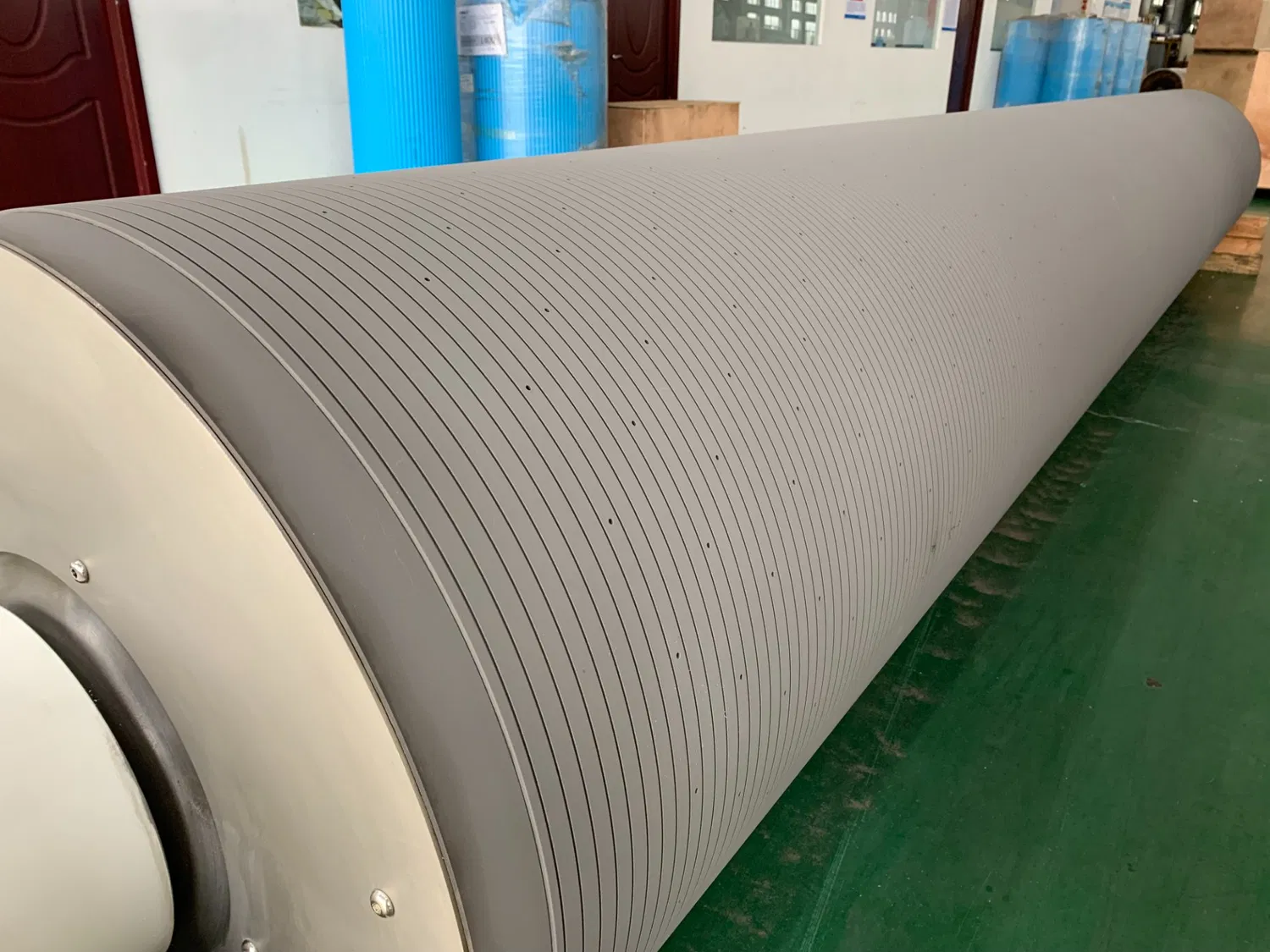

Before we jump into troubleshooting, let's recap the couch roll's core function. Essentially, it's the last roll in the forming section before the paper web is strong enough to support its own weight. The couch roll uses vacuum to remove water and consolidate the fibers, thus increasing the web's strength and dryness before it enters the press section. A properly functioning couch roll ensures a consistent moisture profile and minimizes the risk of web breaks during the transfer. Interestingly, the design and materials of the couch roll, coupled with the applied vacuum levels, significantly affect its performance. Choosing the right type of roll for your specific paper grade and operating conditions is crucial. Have you considered whether your current couch roll configuration is truly optimized for your mill's needs?

Web Breaks: A Frequent Frustration

Web breaks are, without a doubt, one of the most disruptive and costly issues associated with couch rolls. They can be caused by several factors related to the roll itself. Uneven vacuum distribution across the roll face is a common culprit, leading to weak spots in the web. Shell surface issues like cracks, damage, or plugging also contribute to web breaks. A damaged or improperly maintained couch roll surface can create localized pressure points or areas with insufficient drainage, leading to inconsistent web strength. Moreover, the couch roll’s vacuum level being too high or too low can cause the web to either stick excessively or fail to adhere properly during transfer. To diagnose the problem effectively, inspect the shell for damage, measure vacuum levels across the roll face, and check the vacuum system for leaks or blockages. According to my experience, regular inspections and preventative maintenance can significantly reduce the incidence of web breaks.

Moisture Profile Issues: Achieving Consistency

An inconsistent moisture profile is another headache that can stem from couch roll problems. A non-uniform moisture profile can cause quality issues in the final paper product, impacting its printability, strength, and overall appearance. The culprit is often an uneven vacuum profile, as the roll removes water inconsistently across the web. Clogged drainage holes or internal obstructions within the roll's shell can hinder water removal and create wet streaks. In extreme cases, the couch roll's own crown (its curvature) may be inappropriate for the specific web width and machine geometry, leading to localized variations in pressure and water removal. Rectifying this requires careful analysis of the vacuum profile, cleaning or unclogging drainage paths, and potentially adjusting the couch roll's crown. It’s worth noting that regular profile measurements and adjustments are key to ensuring consistent moisture levels.

Runnability Problems and Their Roots

Poor runnability encompasses a range of issues that impact the smooth and efficient operation of the paper machine. Couch roll problems often manifest as instability in the web, difficulty in transferring the web to the press section, and increased downtime. Excessive vibration of the couch roll can disrupt the web and cause breaks. Problems with the roll's bearings or alignment can contribute to vibrations and instability. Moreover, inadequate or excessive sheet release from the roll can hinder transfer and cause sheet fluttering or wrinkles. Addressing runnability problems often requires a comprehensive assessment of the couch roll's mechanical condition, including bearing condition, alignment, and vacuum system performance. Interestingly, sometimes a seemingly minor adjustment to the vacuum level or roll speed can significantly improve runnability.

Vacuum System Maintenance and Optimization

The vacuum system associated with the couch roll is arguably just as important as the roll itself. A poorly maintained or improperly configured vacuum system can negate even the best couch roll design. Leaks in the vacuum lines, clogged separators, and inadequate vacuum pump capacity can all compromise the system's effectiveness. Inefficient water separation can allow water to carry over into the vacuum pumps, damaging them and reducing their efficiency. Regularly inspecting and maintaining the vacuum system is paramount. This includes checking for leaks, cleaning separators, verifying pump performance, and ensuring that the vacuum levels are within the recommended range for the specific paper grade being produced. Remember, a healthy vacuum system translates to a healthier couch roll operation.

Couch Roll Surface Condition and Maintenance

The surface condition of the couch roll is critical for consistent performance. The shell surface should be smooth, free of damage, and offer the proper friction characteristics for optimal sheet release. Surface damage, such as cracks, dents, or erosion, can create localized pressure points and lead to web breaks. Additionally, the surface material itself (often rubber or a composite material) can wear down over time, impacting its water removal capabilities. Regular inspections and maintenance are essential. This involves visually inspecting the surface for damage, measuring surface roughness, and performing necessary repairs or resurfacing as needed. In some cases, specialized coatings can be applied to the roll surface to improve its release characteristics and extend its lifespan. Many professionals believe that proactive surface maintenance is a wise investment.

Case Studies and Practical Applications

To illustrate the importance of proper couch roll maintenance, let's consider a hypothetical case. We company once worked with a paper mill that was experiencing frequent web breaks and inconsistent moisture profiles. After conducting a thorough inspection, we discovered that the couch roll's vacuum system had significant leaks, and the shell surface was damaged in several areas. By repairing the vacuum system, resurfacing the roll, and optimizing the vacuum levels, the mill was able to significantly reduce web breaks and improve the consistency of their paper production. Another example involves a mill that was struggling with poor runnability. In this case, the issue was traced back to misaligned bearings in the couch roll. Realigning the bearings eliminated the vibrations and improved the overall stability of the paper machine. These examples underscore the importance of a holistic approach to troubleshooting couch roll problems.

Preventive Measures and Best Practices

Rather than reacting to problems as they arise, implementing preventive measures and best practices is a much more effective strategy. Establish a regular inspection and maintenance schedule for the couch roll and its associated systems. This should include visual inspections, vacuum system checks, bearing inspections, and surface condition assessments. Train personnel on proper operating procedures and troubleshooting techniques. Maintain detailed records of all inspections, maintenance activities, and performance data. By tracking these metrics over time, you can identify trends and potential problems before they escalate. Furthermore, consider investing in advanced monitoring technologies, such as vibration sensors or vacuum profile monitoring systems, to gain real-time insights into the couch roll's performance. This proactive approach can help prevent costly downtime and improve overall efficiency.

Conclusion: Mastering Couch Roll Optimization

In conclusion, troubleshooting common issues with couch rolls in paper mills requires a comprehensive understanding of the roll's function, the associated systems, and the potential causes of problems. By systematically diagnosing and addressing these issues, mills can minimize web breaks, improve moisture profiles, enhance runnability, and ultimately optimize their paper production processes. The couch roll may seem like just one component of a complex machine, but its proper operation is vital to achieving consistent quality, efficient operation, and a profitable bottom line. Are you ready to prioritize couch roll maintenance and optimization to unlock its full potential within your paper mill?