The Fourdrinier machine, the workhorse of the papermaking industry, relies on a series of carefully orchestrated components to transform pulp into the paper we use every day. Amongst these components, the breast roll plays a pivotal, yet often understated, role. Simply put, the breast roll is the first roll the paper web encounters in the Fourdrinier section, also known as the wet end of the machine. Understanding its function is critical for optimizing paper quality and overall production efficiency. It's more than just a turning point; it's the foundation upon which the entire sheet formation process is built.

The Primary Function: Web Formation Initiation

The core function of the breast roll is to initiate the formation of the paper web. Here's how it works: a slurry of pulp fibers, suspended in water, is pumped onto the moving Fourdrinier wire, a continuously circulating mesh belt. The breast roll, positioned at the very beginning of this wire, is where this initial contact occurs. Its rotation helps to smoothly transfer the pulp suspension from the headbox (which delivers the slurry) onto the wire. This smooth transfer is crucial because any inconsistencies or disturbances at this early stage can propagate through the entire papermaking process, ultimately impacting the final paper quality. A properly functioning breast roll ensures an even distribution of fibers across the wire, which is the first step towards creating a uniform and strong paper sheet.

Influence on Drainage and Water Removal

While the primary function is web formation, the breast roll also indirectly influences drainage and water removal. As the pulp slurry comes into contact with the wire, gravity starts to draw water through the mesh. The rotation of the breast roll, combined with the wire's movement, aids in this initial drainage process. The consistency of the pulp slurry, the wire speed, and the breast roll's speed all play a part in how effectively water is removed at this stage. Insufficient drainage at this early point can lead to a wetter web as it moves down the machine, potentially causing problems with subsequent drainage elements like foils and suction boxes. Therefore, the breast roll sets the stage for the entire drainage sequence.

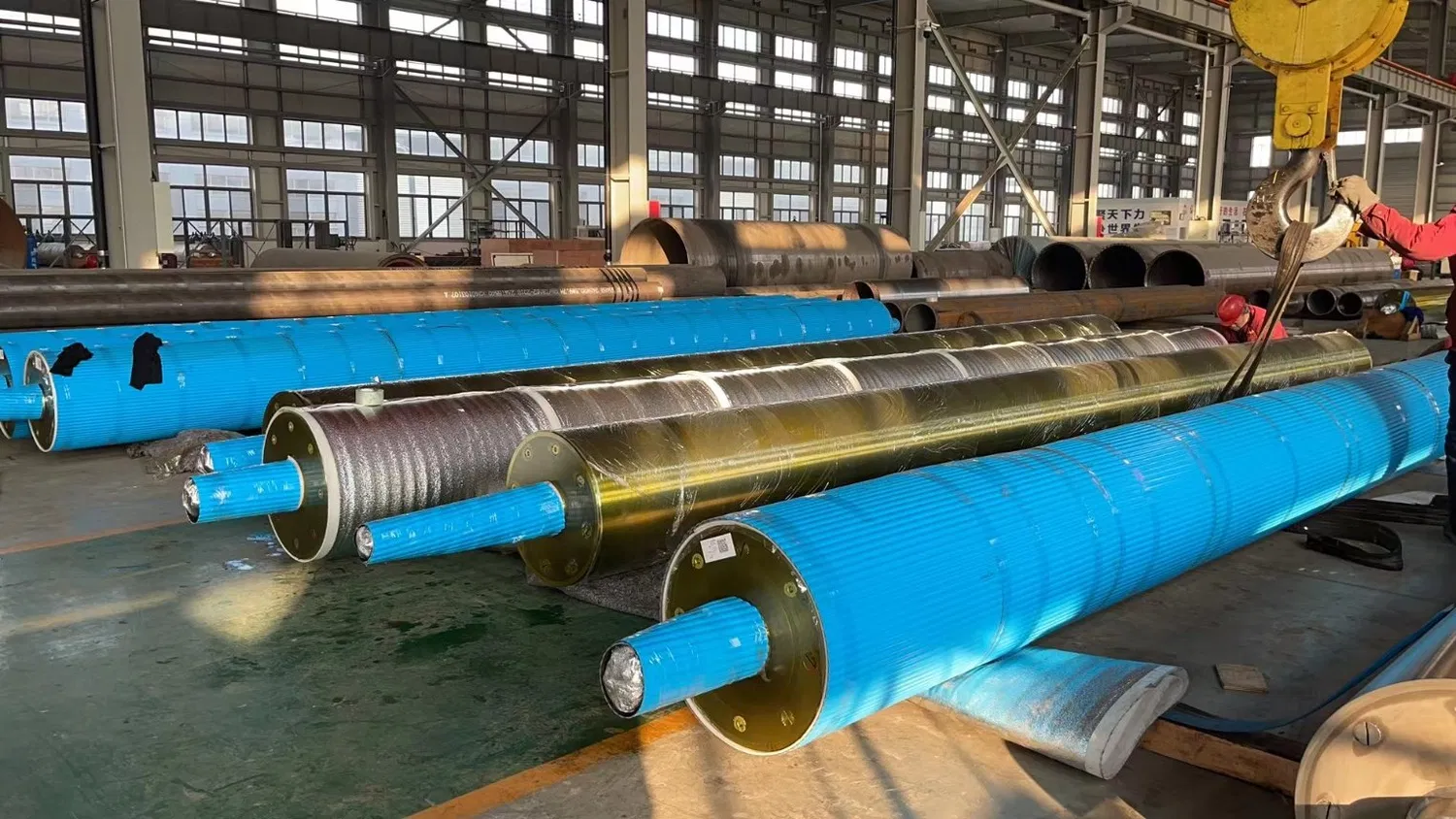

Material and Design Considerations

Breast rolls are typically constructed from durable materials like stainless steel or composite materials to withstand the constant exposure to water and pulp. The surface finish of the roll is also important; a smooth, non-porous surface helps to ensure even transfer of the pulp and prevents fibers from sticking to the roll. The diameter of the breast roll can vary depending on the size and design of the Fourdrinier machine. Larger machines generally require larger breast rolls to handle the increased web width and production speeds. Furthermore, the bearing system supporting the breast roll must be robust and well-maintained to ensure smooth and consistent rotation, minimizing vibrations that could disrupt the web formation process.

Impact on Paper Properties

The operation of the breast roll can significantly affect several key paper properties, including formation, strength, and surface smoothness. Good formation, meaning a uniform distribution of fibers, leads to improved strength and a more consistent basis weight. A properly aligned and rotating breast roll ensures this even distribution from the very beginning. In contrast, a misaligned or damaged breast roll can cause uneven fiber distribution, leading to weak spots and variations in sheet thickness. Furthermore, the initial water removal influenced by the breast roll impacts how the fibers orient themselves during the subsequent drying stages, ultimately affecting the final sheet's smoothness and printability.

Maintenance and Troubleshooting

Regular maintenance of the breast roll is crucial for maintaining optimal paper quality and preventing costly downtime. This includes regular inspections for wear and tear, cleaning to remove accumulated pulp and debris, and lubrication of the bearings. Common problems associated with breast rolls include misalignment, surface damage, and bearing failure. Misalignment can be detected by observing uneven sheet formation or variations in moisture content across the web. Surface damage, such as scratches or dents, can cause streaks or other imperfections in the paper. Bearing failure is usually indicated by excessive noise or vibration. Addressing these issues promptly is essential to avoid further damage and maintain consistent paper production.

Practical Applications and Real-World Examples

In a specific case study, we at our company worked with a paper mill that was experiencing inconsistent sheet formation and frequent web breaks. After a thorough investigation, we discovered that the breast roll was slightly misaligned. Correcting the alignment of the breast roll resulted in a significant improvement in sheet formation, a reduction in web breaks, and an overall increase in production efficiency. This real-world example highlights the critical role of the breast roll and the importance of proper maintenance and alignment. It’s a reminder that even seemingly minor issues with this component can have a significant impact on the entire papermaking process. Many professional papermakers will agree on the positive impact of a well maintained breast roll on the final product.

Advanced Control Strategies

Modern Fourdrinier machines often incorporate advanced control strategies to optimize the performance of the breast roll. These strategies may involve sensors that monitor the wire tension, the consistency of the pulp slurry, and the speed of the breast roll. This data is then used to automatically adjust the roll's speed and position to maintain optimal web formation and drainage. Some systems also incorporate automated cleaning devices to prevent pulp buildup and maintain a consistent surface finish on the roll. These advanced control strategies help to ensure consistent paper quality, reduce waste, and improve overall production efficiency. You might ask, “Are these strategies expensive to implement?” and the answer is, it depends on the scale of your operation, but the returns are often significant.

Beyond the Basics: Emerging Technologies

While the fundamental function of the breast roll remains largely unchanged, there are ongoing advancements in its design and materials. For example, some manufacturers are experimenting with new composite materials that offer improved durability and resistance to wear. Others are developing innovative surface coatings that reduce fiber adhesion and improve drainage. Additionally, research is being conducted on using advanced sensors and control algorithms to further optimize the performance of the breast roll and the entire wet end of the Fourdrinier machine. These emerging technologies promise to further enhance paper quality, reduce waste, and improve the overall efficiency of the papermaking process. Speaking of which, have you considered how automation could further optimize your current papermaking process?

The Future of Breast Roll Technology

Looking ahead, the future of breast roll technology will likely focus on further optimizing web formation, improving drainage efficiency, and reducing maintenance requirements. This may involve the development of new materials, advanced control systems, and innovative cleaning techniques. As the demand for higher quality paper and more sustainable papermaking practices continues to grow, the breast roll will undoubtedly remain a critical component of the Fourdrinier machine, playing a key role in meeting these evolving needs. According to my experience, innovations in this area will be crucial for the paper industry's future competitiveness.

Conclusion: A Foundational Element

In conclusion, understanding the function of the breast roll in Fourdrinier machines is paramount for anyone involved in the papermaking process. From initiating web formation and influencing drainage to impacting final paper properties, the breast roll plays a vital role in determining the quality and consistency of the finished product. By paying close attention to its design, maintenance, and operation, paper manufacturers can optimize their production processes, reduce waste, and ensure the delivery of high-quality paper to meet the ever-evolving demands of the market. So, the next time you hold a sheet of paper, remember the crucial role of the breast roll in its creation.