Roll surface treatments play a pivotal, though often unseen, role in shaping the characteristics of the paper we use every day. From the glossy pages of magazines to the sturdy cardboard boxes that protect our deliveries, the final quality and functionality of paper are significantly influenced by how the rolls involved in its production are treated. These treatments aren't just superficial; they fundamentally alter the surface properties of the rolls, which in turn dictate how the paper pulp interacts with them during the manufacturing process. The goal is always to optimize the paper's characteristics – its smoothness, its ability to absorb ink, its strength, and even its appearance.

Understanding Roll Surface Treatments

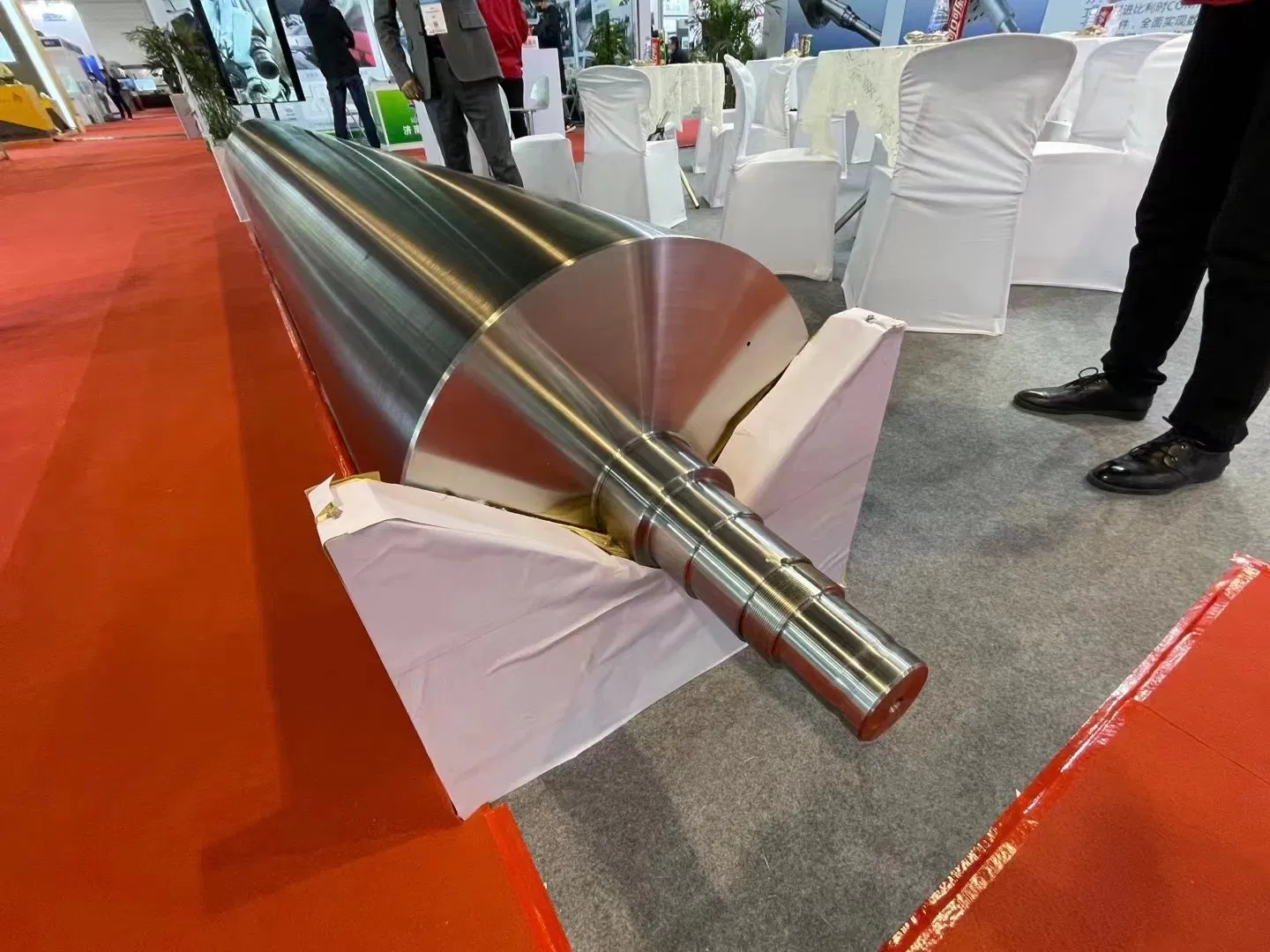

To fully grasp the impact of roll surface treatments, it's essential to understand what these treatments actually are. Essentially, they involve modifying the surface of the rolls used in paper mills to achieve specific outcomes. These rolls, often massive cylinders of steel or other materials, are critical components in processes like calendaring (smoothing the paper) and coating (applying a surface layer for improved printability or protection). Treatments can range from simple polishing to create a highly smooth surface, to complex chemical applications that alter the roll's surface energy. For example, some treatments create a micro-textured surface, which enhances the grip of the roll on the paper web, while others create a non-stick surface, preventing the paper from adhering to the roll. The selection of the appropriate treatment depends entirely on the desired properties of the final paper product.

The Impact on Paper Smoothness

One of the most direct and noticeable effects of roll surface treatments is on the smoothness of the paper. Calendaring rolls, in particular, undergo rigorous surface treatments to achieve exceptionally smooth surfaces. When paper passes between these rolls under immense pressure, its surface irregularities are flattened, resulting in a smoother, more uniform sheet. Different treatments can achieve varying degrees of smoothness. For instance, rolls coated with specific polymers or treated with specialized polishing techniques can produce paper with a glass-like surface, ideal for high-quality printing. In contrast, treatments that create a slightly textured roll surface might be preferred for paper intended for writing, as it provides better ink adhesion and prevents smudging. So, while smoothness might seem like a simple attribute, the level of control afforded by roll surface treatments allows for the fine-tuning of this property to match the specific needs of the application.

Enhancing Paper Printability

The printability of paper is another critical characteristic significantly influenced by roll surface treatments. Consider coated papers, often used in magazines and brochures, which boast vibrant colors and sharp images. The coating process itself relies heavily on specialized rolls designed to apply a thin, even layer of coating material to the paper's surface. These rolls might be treated with specific polymers or chemicals to control the coating's adhesion, flow, and drying properties. Furthermore, the surface texture of the coating roll directly impacts the smoothness and uniformity of the applied coating, which in turn affects how ink interacts with the paper. A well-treated roll ensures that the coating is evenly distributed, minimizing imperfections that could lead to blurred images or uneven color distribution. In essence, roll surface treatments are indispensable for producing paper that consistently delivers high-quality printing results. What other factors do you think influence a paper's ability to be printed on effectively?

Improving Paper Strength and Durability

While smoothness and printability are often the focus, roll surface treatments also play a role in enhancing the strength and durability of paper. In processes like pressing and drying, rolls are used to consolidate the paper web and remove excess moisture. The surface characteristics of these rolls can influence the fiber bonding within the paper sheet. For example, a roll with a slightly textured surface might promote better fiber entanglement, leading to a stronger and more tear-resistant paper. Similarly, specific surface treatments can improve the roll's ability to uniformly distribute pressure across the paper web, minimizing stress concentrations that could lead to weaknesses. In the production of cardboard, for example, rolls are often treated to ensure that the corrugated layers are securely bonded, resulting in a robust and durable packaging material. Therefore, roll surface treatments contribute to not only the aesthetic qualities of paper but also its functional performance.

Specific Examples and Applications

Let’s dive into some concrete examples. Take the production of photographic paper. Here, rolls with extremely smooth and precisely controlled surfaces are used to apply the photosensitive emulsion. Any imperfections in the roll surface would directly translate into defects in the final image. Similarly, in the manufacturing of labels, specialized rolls are employed to apply adhesives. The surface energy of these rolls must be carefully controlled to ensure that the adhesive is transferred evenly and efficiently to the label stock. The corrugated cardboard industry provides another excellent example. Rolls with specific surface patterns are used to create the characteristic corrugations, and the surface treatments ensure that these corrugations are consistent and strong. These examples underscore the crucial role of roll surface treatments in achieving the desired properties of various paper products.

The Role of Material Science

The development and application of roll surface treatments are deeply rooted in material science. The selection of the appropriate treatment depends on the material properties of the roll itself, as well as the specific demands of the paper manufacturing process. For example, certain polymers might be chosen for their ability to resist wear and tear, while others might be selected for their chemical inertness. Surface treatments can involve techniques like plasma coating, which deposits a thin layer of a different material onto the roll surface, altering its properties without affecting the bulk material. The field is constantly evolving, with new materials and techniques being developed to further optimize paper properties. Indeed, the collaboration between material scientists and paper manufacturers is essential for driving innovation in this area.

Challenges and Future Trends

While roll surface treatments offer significant benefits, they also present certain challenges. Maintaining the integrity of the treated surface over time is a major concern, as wear and tear can degrade the performance of the roll. Regular maintenance and re-treatment are often necessary. Furthermore, the cost of specialized surface treatments can be a significant factor, especially for smaller paper mills. Looking ahead, there is a growing emphasis on developing more sustainable and environmentally friendly treatment options. Researchers are exploring the use of bio-based materials and more energy-efficient application techniques. The future of roll surface treatments will likely involve a greater focus on minimizing environmental impact while continuing to enhance the quality and performance of paper products. Considering that, what environmentally friendly materials do you think could be used in the future?

The Importance of Precision and Control

One thing that stands out is the emphasis on precision and control. The effectiveness of roll surface treatments hinges on the ability to precisely control the application process and the characteristics of the resulting surface. This requires sophisticated equipment, skilled technicians, and rigorous quality control procedures. Variations in temperature, pressure, and application speed can all affect the outcome. Many manufacturers use advanced monitoring systems to track the performance of their rolls and detect any signs of wear or degradation. The pursuit of ever-greater precision and control is a constant driving force in the field.

A Critical Component of Paper Manufacturing

To summarize, roll surface treatments are not just an afterthought in paper manufacturing; they are a critical component that directly influences the quality, performance, and functionality of the final product. From enhancing smoothness and printability to improving strength and durability, these treatments play a multifaceted role. While they might seem like a niche area, their impact is far-reaching, affecting everything from the magazines we read to the packaging that protects our goods. The continuous innovation in material science and treatment techniques promises even greater advancements in the future, leading to even higher quality and more sustainable paper products.

Conclusion: Enhancing Paper Through Roll Surface Treatments

In conclusion, how roll surface treatments enhance paper properties is a complex and multifaceted topic that underpins the production of a wide range of paper products. By carefully manipulating the surfaces of the rolls used in manufacturing, we can tailor the characteristics of paper to meet specific needs, whether it's achieving a glossy finish for high-quality printing or increasing the strength for robust packaging. The science and technology behind these treatments are constantly evolving, driven by the desire for improved performance, sustainability, and cost-effectiveness. Ultimately, understanding the impact of roll surface treatments provides a deeper appreciation for the intricate processes involved in bringing paper to our everyday lives.

`