Roll maintenance is, quite frankly, the unsung hero of countless industries. From paper mills to steel plants, printing presses to plastic extrusion facilities, rollers are the workhorses that keep production lines humming. But like any hardworking component, they require regular maintenance to ensure optimal performance, prevent costly downtime, and extend their lifespan. This comprehensive guide will delve into the various tools and technologies employed in roll maintenance, providing a detailed overview of the methods and equipment essential for keeping your rollers in top condition. We'll explore the intricacies of grinding, inspection, and surface finishing, offering practical insights and real-world examples to illustrate the importance of each process.

Roll Grinding Technologies

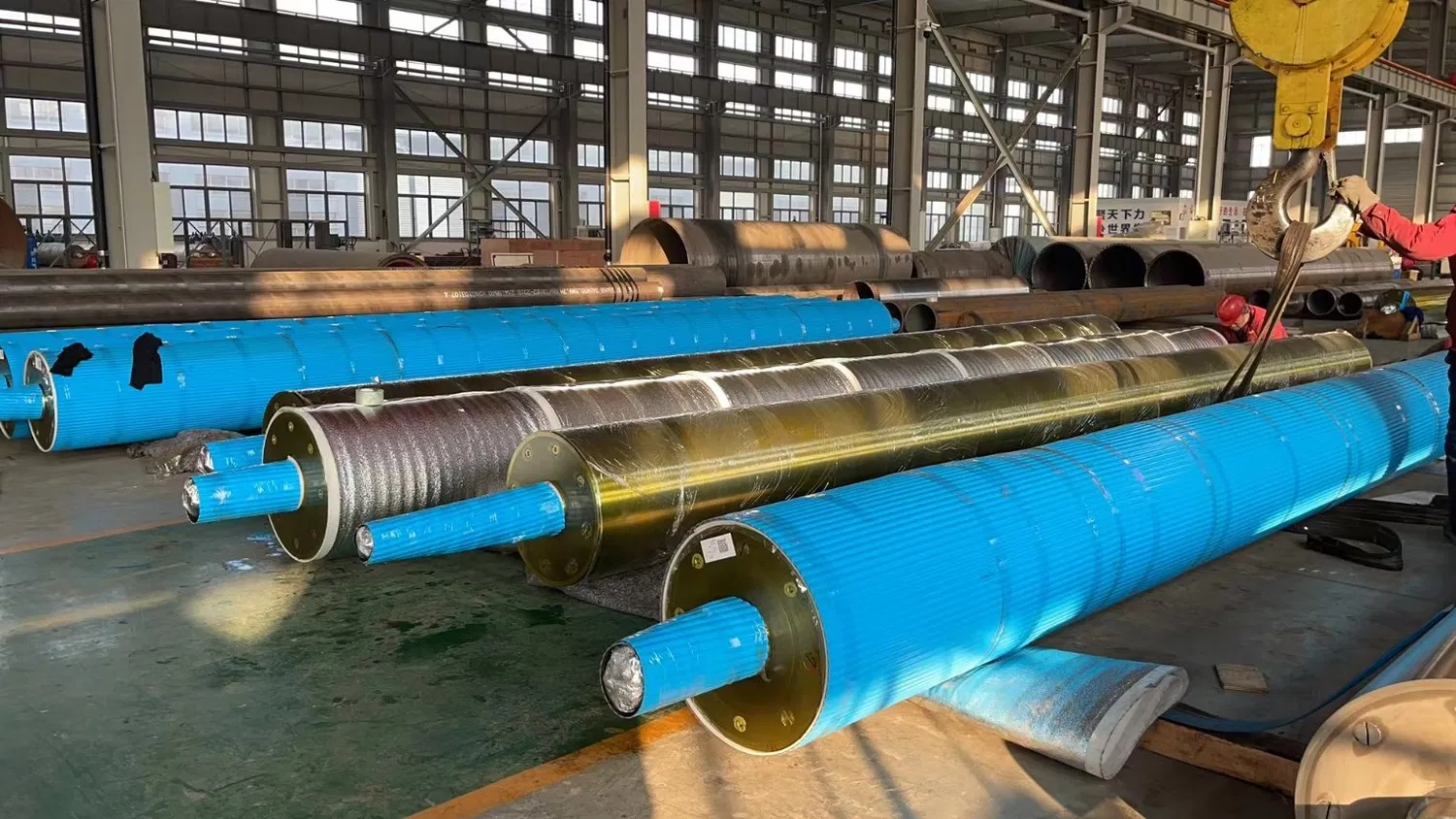

Roll grinding is perhaps the most critical aspect of roll maintenance. Over time, rollers can develop imperfections such as surface wear, scoring, and deviations from their original profile. Grinding removes these imperfections, restoring the roller to its precise dimensions and surface finish. Modern roll grinding machines are sophisticated pieces of equipment, often incorporating CNC (Computer Numerical Control) technology for unparalleled accuracy and repeatability. These machines can handle a wide range of roller sizes and materials, from hardened steel to specialized coatings. The selection of the appropriate grinding wheel is crucial, as different wheels are designed for specific materials and desired surface finishes. Furthermore, the grinding process itself requires careful control of parameters such as grinding speed, feed rate, and coolant application to avoid overheating and damage to the roller. The advancements in grinding technology have made it possible to achieve incredibly precise surface finishes, often measured in microinches, contributing to improved product quality and reduced friction.

Advanced Roll Inspection Techniques

Inspection plays a vital role in identifying potential problems before they escalate into major failures. Traditional inspection methods often rely on visual examination and manual measurements using tools like calipers and micrometers. While these methods are still valuable, they can be time-consuming and subjective. Modern inspection techniques, however, offer a more objective and comprehensive assessment of roll condition. Non-destructive testing (NDT) methods such as ultrasonic testing (UT) and magnetic particle inspection (MPI) can detect internal flaws and surface cracks that are invisible to the naked eye. Furthermore, 3D scanning and laser profilometry can generate highly accurate digital models of roller surfaces, allowing for precise measurement of dimensions, roundness, and surface roughness. These digital models can be compared to the original design specifications to identify deviations and potential areas of concern. Interesting to note, some companies are developing AI-powered inspection systems that can automatically analyze inspection data and flag potential problems, further streamlining the maintenance process and improving accuracy.

Surface Finishing and Coating Technologies

The surface finish of a roller is a critical factor in its performance. The desired surface finish depends on the specific application. For example, rollers used in paper mills often require a highly polished surface to prevent paper tearing and ensure uniform web tension. On the other hand, rollers used in plastic extrusion may require a textured surface to improve grip and prevent slippage. Various surface finishing techniques are available, including polishing, honing, and lapping. Coating technologies are also widely used to enhance the performance and durability of rollers. Common coatings include chrome plating, ceramic coatings, and polymer coatings. Chrome plating provides excellent wear resistance and corrosion protection. Ceramic coatings offer high hardness and thermal stability, making them suitable for demanding applications. Polymer coatings can provide specific properties such as non-stick surfaces or enhanced friction. The selection of the appropriate surface finishing and coating technology depends on the specific requirements of the application and the material of the roller. Did you know that the right coating can dramatically extend the life of a roller, saving significant costs in the long run?

The Impact of Lubrication on Roll Longevity

Beyond grinding, inspection, and surface treatment, proper lubrication is paramount to the longevity and performance of industrial rollers. Lubrication reduces friction, minimizing wear and tear on the roller surface and bearings. Selecting the correct lubricant is crucial; factors to consider include the operating temperature, load, speed, and the materials of the roller and its bearings. Different lubricants offer varying degrees of viscosity, thermal stability, and resistance to contamination. Automated lubrication systems are becoming increasingly popular, delivering precise amounts of lubricant at regular intervals, ensuring consistent and optimal lubrication. These systems can significantly reduce manual labor and prevent over- or under-lubrication, both of which can lead to premature failure. Moreover, monitoring lubricant condition is essential; regular oil analysis can detect contamination, degradation, and wear particles, providing early warning signs of potential problems. Proper lubrication, often underestimated, is a cornerstone of proactive roll maintenance.

Case Study: Roll Maintenance in the Printing Industry

To illustrate the practical application of roll maintenance, consider the printing industry. Printing presses rely on a series of rollers to transfer ink onto paper. These rollers are subjected to constant wear and tear, as well as exposure to harsh chemicals in the inks. Regular roll maintenance is essential to ensure consistent print quality and prevent costly downtime. Printing companies typically implement a comprehensive roll maintenance program that includes regular inspection, cleaning, and grinding. Rollers are inspected for surface damage, ink buildup, and dimensional accuracy. Cleaning removes ink residue and contaminants that can affect ink transfer. Grinding restores the roller surface to its original profile, ensuring uniform ink distribution. In addition to these routine maintenance tasks, printing companies may also employ specialized coatings to enhance the performance and durability of their rollers. By investing in proactive roll maintenance, printing companies can minimize downtime, improve print quality, and extend the lifespan of their printing presses.

The Economic Benefits of Proactive Roll Maintenance

The economic benefits of proactive roll maintenance are often substantial. While the initial investment in maintenance tools and technologies may seem significant, it pales in comparison to the costs associated with equipment downtime, reduced production efficiency, and premature roller replacement. Downtime can disrupt production schedules, leading to lost revenue and customer dissatisfaction. Reduced production efficiency can result in lower output and increased waste. Premature roller replacement can be a significant expense, particularly for large or specialized rollers. By implementing a comprehensive roll maintenance program, companies can minimize these costs and maximize the return on their investment in rolling equipment. According to my experience, companies that prioritize roll maintenance often see a significant improvement in their overall operational efficiency and profitability. Why is this proactive approach so crucial? It's all about preventing problems before they arise.

Choosing the Right Roll Maintenance Partner

For many companies, outsourcing roll maintenance to a specialized service provider is the most cost-effective and efficient option. A reputable roll maintenance partner will have the expertise, equipment, and experience to handle all aspects of roll maintenance, from inspection and grinding to coating and repair. When selecting a roll maintenance partner, it's essential to consider their experience, reputation, and capabilities. Look for a partner with a proven track record of providing high-quality service and meeting the specific needs of your industry. Check their certifications and accreditations to ensure they meet industry standards. Ask for references from other clients and contact them to get feedback on their experience. It's also important to understand their pricing structure and payment terms. A transparent and competitive pricing structure is a sign of a reputable partner. Ultimately, choosing the right roll maintenance partner can be a strategic decision that contributes to improved equipment performance, reduced downtime, and increased profitability.

Future Trends in Roll Maintenance Technology

The field of roll maintenance is constantly evolving, with new technologies and techniques emerging all the time. One of the most exciting trends is the increasing use of automation and robotics. Automated grinding machines and inspection systems are becoming more sophisticated, allowing for greater precision and efficiency. Robotics are being used to automate repetitive tasks such as cleaning and polishing. Another important trend is the development of predictive maintenance techniques. By using sensors and data analytics, it's possible to monitor the condition of rollers in real-time and predict when maintenance will be required. This allows companies to proactively address potential problems before they lead to downtime. Additive manufacturing, also known as 3D printing, is also starting to play a role in roll maintenance. 3D printing can be used to create custom roller components and repair damaged rollers. As these technologies continue to develop, they will undoubtedly transform the way roll maintenance is performed in the future. The future,坦白讲, looks bright for those who embrace these advancements.

Staying Ahead with Roll Maintenance Knowledge

Keeping up with the latest advancements in roll maintenance tools and technologies is essential for any company that relies on rolling equipment. There are several ways to stay informed. Attend industry conferences and trade shows to learn about new products and services. Read industry publications and online resources to stay up-to-date on the latest trends. Network with other professionals in the field to share knowledge and best practices. Furthermore, consider investing in training for your maintenance personnel to ensure they have the skills and knowledge necessary to perform roll maintenance effectively. By staying informed and investing in training, you can ensure that your company is equipped to optimize the performance and lifespan of its rolling equipment.

In conclusion, roll maintenance is a multifaceted discipline encompassing various tools and technologies, each contributing to the optimal performance and longevity of industrial rollers. From the precision of CNC grinding and the detail of advanced inspection techniques to the protective power of surface coatings and the crucial role of lubrication, every aspect of roll maintenance plays a vital part. By understanding and implementing these best practices, industries can minimize downtime, enhance product quality, and maximize the return on their investment in rolling equipment. Remember, proactive roll maintenance is not just a cost; it's an investment in your future. Have you considered how a comprehensive roll maintenance program could benefit your specific operations? It's worth exploring. `