High-speed paper machines demand precision and reliability in every component, and rolls are no exception. Effective roll design is paramount to achieving optimal paper quality, maximizing production speed, and minimizing downtime. This article delves into the key considerations for roll design in high-speed paper machines, offering practical insights for improved performance.

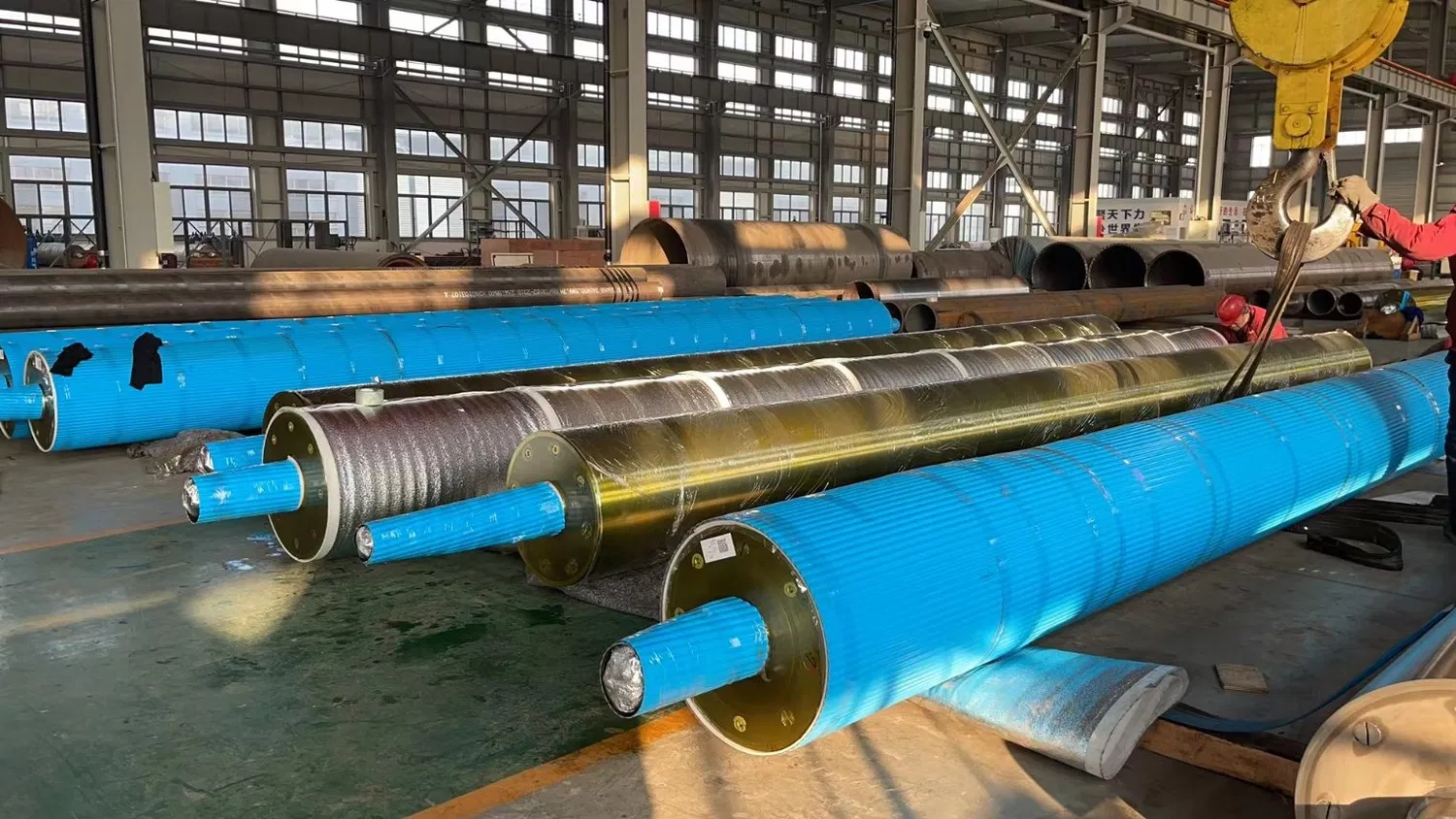

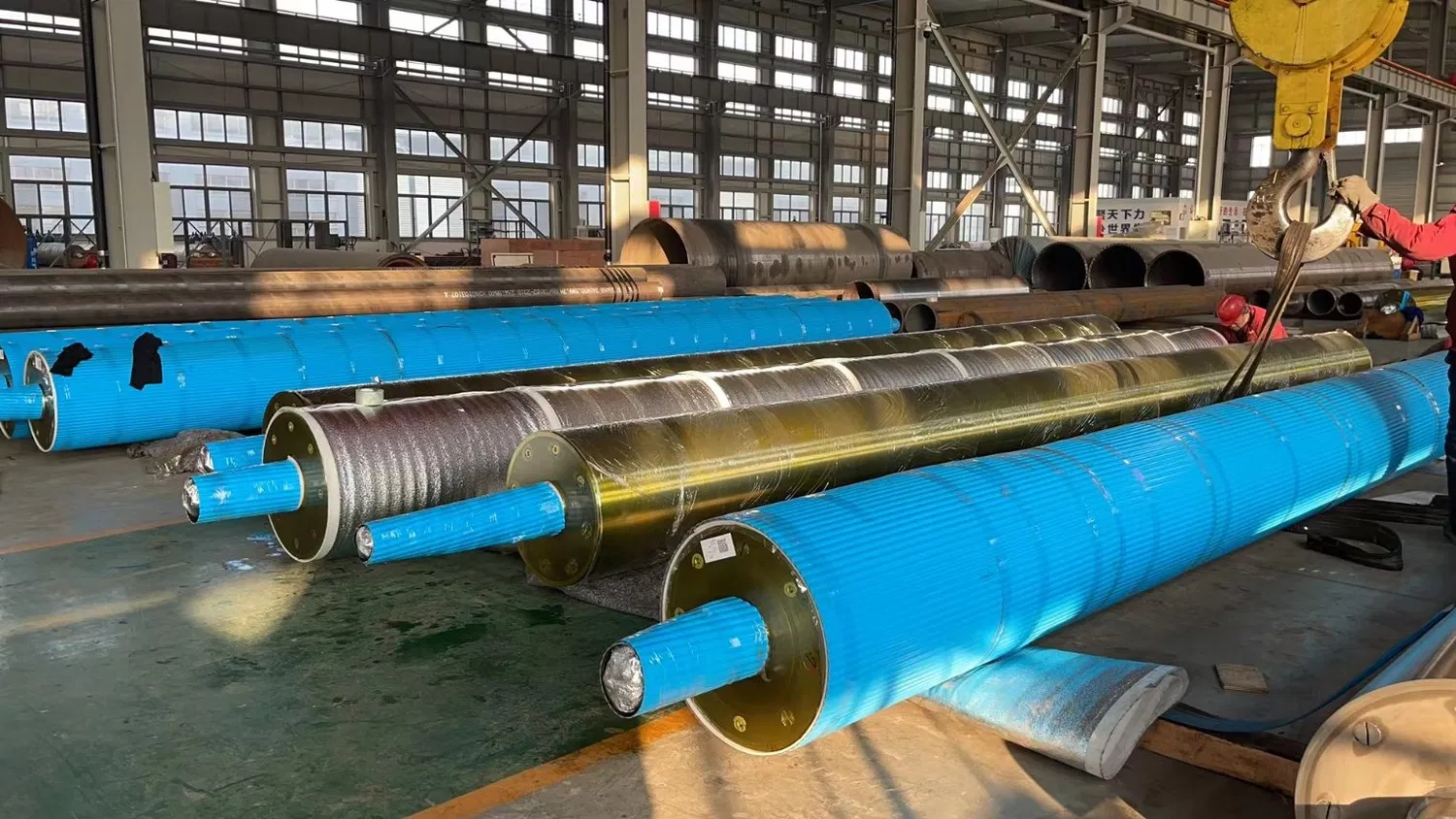

Material Selection: Balancing Performance and Durability

Choosing the right material is the foundation of robust roll design. Factors like operating temperature, chemical exposure, and required hardness all influence the ideal material. Common choices include stainless steel, carbon steel, and various composites. For instance, stainless steel offers excellent corrosion resistance, while carbon steel provides high strength and stiffness. However, composite materials are gaining popularity due to their lightweight nature and customizable properties. What material best suits your specific operating conditions?

Nip Pressure Optimization: The Key to Uniformity

Nip pressure, the force exerted between two rolls, plays a critical role in paper properties like caliper and smoothness. Precise control over nip pressure is crucial for achieving consistent paper quality and preventing defects. Excessive nip pressure can lead to sheet breaks and roll wear, while insufficient pressure can result in uneven caliper and poor surface finish. Sophisticated control systems are essential for maintaining optimal nip pressure across the entire paper web.

Dynamic Balancing: Minimizing Vibrations and Extending Roll Life

High-speed rotation generates significant centrifugal forces, making dynamic balancing crucial for roll stability. Imbalance can lead to vibrations, premature bearing failure, and even roll damage. Precise dynamic balancing minimizes these risks, extending roll lifespan and ensuring smooth operation. Regular balancing checks and adjustments are essential for maintaining optimal performance.

Roll Coverings: Tailoring Performance to Specific Needs

Roll coverings significantly influence the paper's surface properties and the overall efficiency of the papermaking process. Different coverings cater to specific needs, from improving sheet release to enhancing water removal. Choosing the right covering depends on factors like paper grade, machine speed, and desired finish. Considering the range of available options, how do you select the optimal covering for your high-speed paper machine?

Roll Diameter and Crown: Influencing Paper Properties and Runnability

The diameter and crown of a roll directly impact paper properties like caliper and moisture profile. A larger diameter generally leads to a smoother paper surface, while the crown compensates for roll deflection under load, ensuring uniform nip pressure across the width of the paper web. Precise control over these parameters is essential for optimizing paper quality and machine runnability.

Thermal Management: Controlling Temperature for Consistent Quality

Temperature variations across the roll can lead to inconsistencies in paper properties and even web breaks. Effective thermal management systems, such as internal cooling or heating, are vital for maintaining uniform temperature distribution and ensuring consistent paper quality, especially in high-speed operations.

Roll Design for High-Speed Paper Machines: A Holistic Approach

Designing rolls for high-speed paper machines necessitates a holistic approach, considering the interplay between material selection, nip pressure, dynamic balancing, coverings, diameter, crown, and thermal management. Each factor contributes to the overall performance and efficiency of the papermaking process.

Maintenance and Inspection: Proactive Measures for Longevity

Regular maintenance and inspection are crucial for maximizing roll lifespan and preventing costly downtime. This includes periodic cleaning, lubrication, and inspection for wear and tear. Implementing a proactive maintenance schedule helps identify potential issues early on, minimizing disruptions to production and extending the life of your rolls.

As paper machine speeds continue to increase, roll design will play an even more critical role in achieving optimal performance. Future developments in materials science, sensor technology, and control systems will further enhance roll performance, leading to improved paper quality, reduced energy consumption, and increased production efficiency.

Next Steps: Optimizing Your Roll Design

To optimize the roll design for your high-speed paper machine, consider partnering with experienced roll manufacturers and service providers. They can provide expert guidance on material selection, covering options, and maintenance strategies tailored to your specific needs, ultimately maximizing your paper machine’s performance and profitability.