Rolls of material, whether paper, film, or foil, are ubiquitous in various industries. However, their unique shape and sometimes delicate nature make them susceptible to damage during handling and storage. Implementing best practices for roll handling and storage is crucial for maintaining product quality, minimizing waste, and ultimately, saving money. This article will explore the most effective techniques for preventing damage throughout the entire process.

Choosing the Right Equipment

Selecting appropriate handling equipment is the first step in preventing roll damage. Using the wrong equipment can lead to dents, scratches, and even core damage. Consider investing in specialized equipment like roll clamps, shaftless chucks, and vacuum lifters. These tools are designed to handle rolls securely and minimize the risk of surface imperfections. For smaller rolls, manual handling equipment with rubberized grips can provide a secure and damage-free handling solution. Are you using the right tools for your specific roll type and weight?

Safe Transportation Techniques

Once you have the correct equipment, understanding how to use it effectively is vital. During transportation, ensure rolls are secured properly to prevent shifting and rolling. Use appropriate restraints like straps or chains, and ensure the transportation vehicle's surface is clean and free of debris. Consider using specialized roll trailers equipped with air-ride suspension to minimize vibrations and shocks during transit. This is especially crucial for sensitive materials susceptible to damage from even minor impacts. Proper roll handling and storage during transportation is essential for maintaining product integrity.

Effective Storage Solutions

Proper storage is just as important as careful handling. The storage environment plays a significant role in preventing damage. Maintaining a clean, dry, and temperature-controlled warehouse is crucial for preventing issues like moisture damage, warping, and degradation. Consider implementing a first-in, first-out (FIFO) system to minimize the time rolls spend in storage and reduce the risk of long-term damage.

Implementing a FIFO System for Roll Storage

A FIFO system ensures that the oldest rolls are used first, minimizing the risk of obsolescence and age-related deterioration. This method is particularly important for materials with a limited shelf life. Proper labeling and inventory management are key components of an effective FIFO system, allowing for easy identification and retrieval of rolls. This contributes significantly to efficient roll handling and storage.

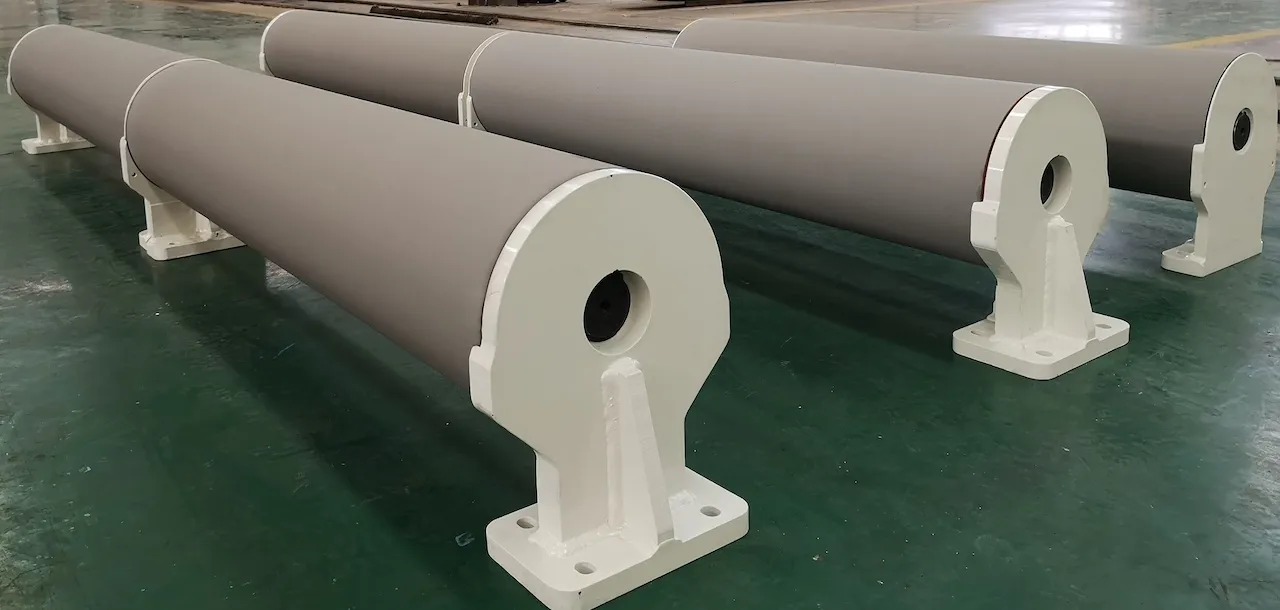

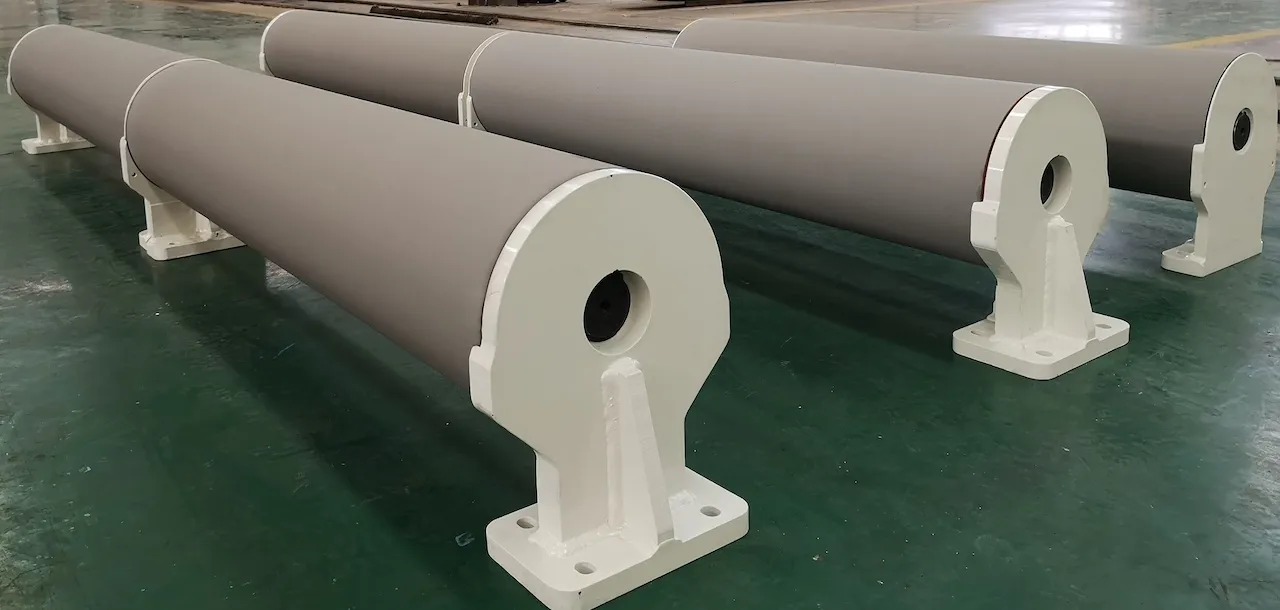

Utilizing Vertical Storage Space

Maximize warehouse space and improve accessibility by implementing vertical storage solutions. Cantilever racking and specialized roll cradles allow for safe and efficient vertical stacking of rolls, freeing up valuable floor space. This also contributes to better organization and easier inventory management, further optimizing roll handling and storage procedures.

Regular Inspection and Maintenance

Regular inspection and maintenance of both rolls and handling equipment are vital for preventing damage. Inspect rolls for signs of damage upon arrival and before storage. Similarly, regularly maintain handling equipment to ensure it is functioning correctly. Address any issues promptly to prevent further damage and maintain operational efficiency. This proactive approach to roll handling and storage can save you time and resources in the long run.

Training and Education

Investing in proper training for employees involved in roll handling and storage is essential. Well-trained personnel are less likely to make mistakes that could lead to damage. Training should cover proper equipment operation, safe lifting techniques, and best practices for storage and transportation. This empowers your workforce to handle rolls efficiently and safely, minimizing the risk of damage and maximizing productivity. Roll handling and storage best practices should be ingrained in every step of the process.

Damage Prevention Strategies: Packaging and Protection

Consider using protective packaging, such as edge protectors, corner boards, and shrink wrap, to minimize the risk of surface damage during handling and storage. This extra layer of protection can be particularly beneficial for sensitive materials prone to scratching or denting. Effective packaging is a crucial component of comprehensive roll handling and storage procedures.

Responding to Damage: A Contingency Plan

Despite best efforts, damage can sometimes occur. Having a contingency plan in place is crucial for minimizing the impact of such incidents. This plan should include procedures for assessing the damage, documenting the incident, and taking corrective actions. It should also address how to handle damaged rolls, including disposal or repair procedures. How do you currently handle damaged rolls in your facility? Having a clear protocol for handling damaged rolls is an essential part of efficient roll handling and storage.

By implementing these best practices for roll handling and storage, you can significantly reduce the risk of damage, maintain product quality, improve efficiency, and ultimately enhance your bottom line. Remember, investing in proper equipment, training, and procedures is an investment in the long-term success of your business.