Paper, a seemingly simple material, has a complex and fascinating production process. At the heart of this process lies the paper machine, a marvel of engineering with a history intertwined with the evolution of its core component: the paper machine roll. From basic wooden cylinders to today's sophisticated, high-performance rolls, the journey of paper machine roll technology mirrors the advancements in papermaking itself. This article explores this remarkable evolution, highlighting the key innovations and their impact on the industry.

Early Days: The Foundation of Paper Machine Rolls

The earliest paper machine rolls were simple wooden structures, often prone to warping, cracking, and wear. These rudimentary rolls limited paper production speed and quality. Imagine trying to create a smooth, consistent sheet of paper with a roller that itself was uneven! As the demand for paper grew, so did the need for more durable and efficient roll materials.

The Metal Age: Increased Durability and Performance

The introduction of metal rolls, particularly cast iron and later steel, marked a significant leap forward. These robust materials offered superior durability and stability, allowing for higher machine speeds and improved paper quality. This era also saw the beginnings of specialized roll coverings, initially using materials like rubber and cotton, to further enhance performance.

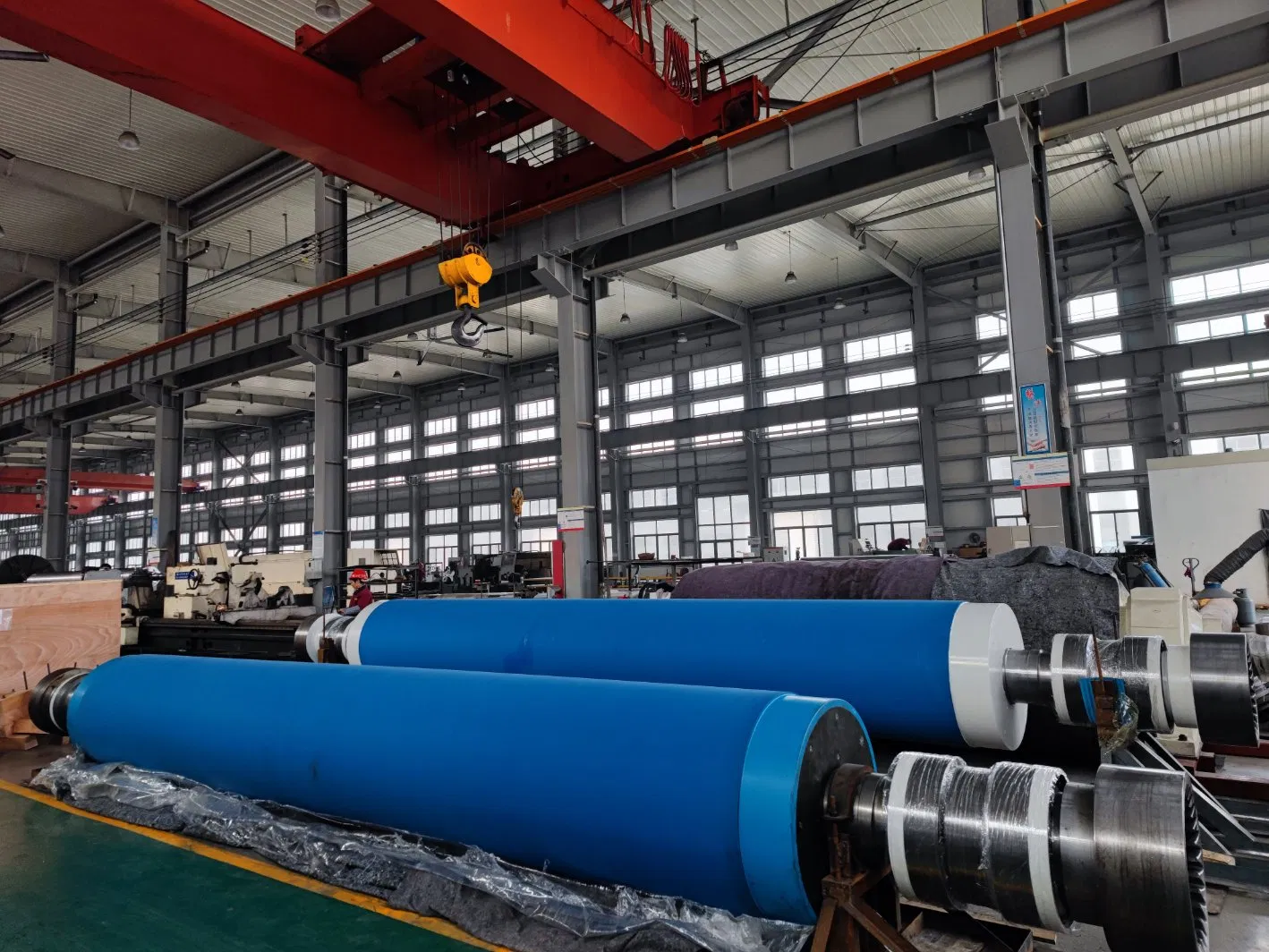

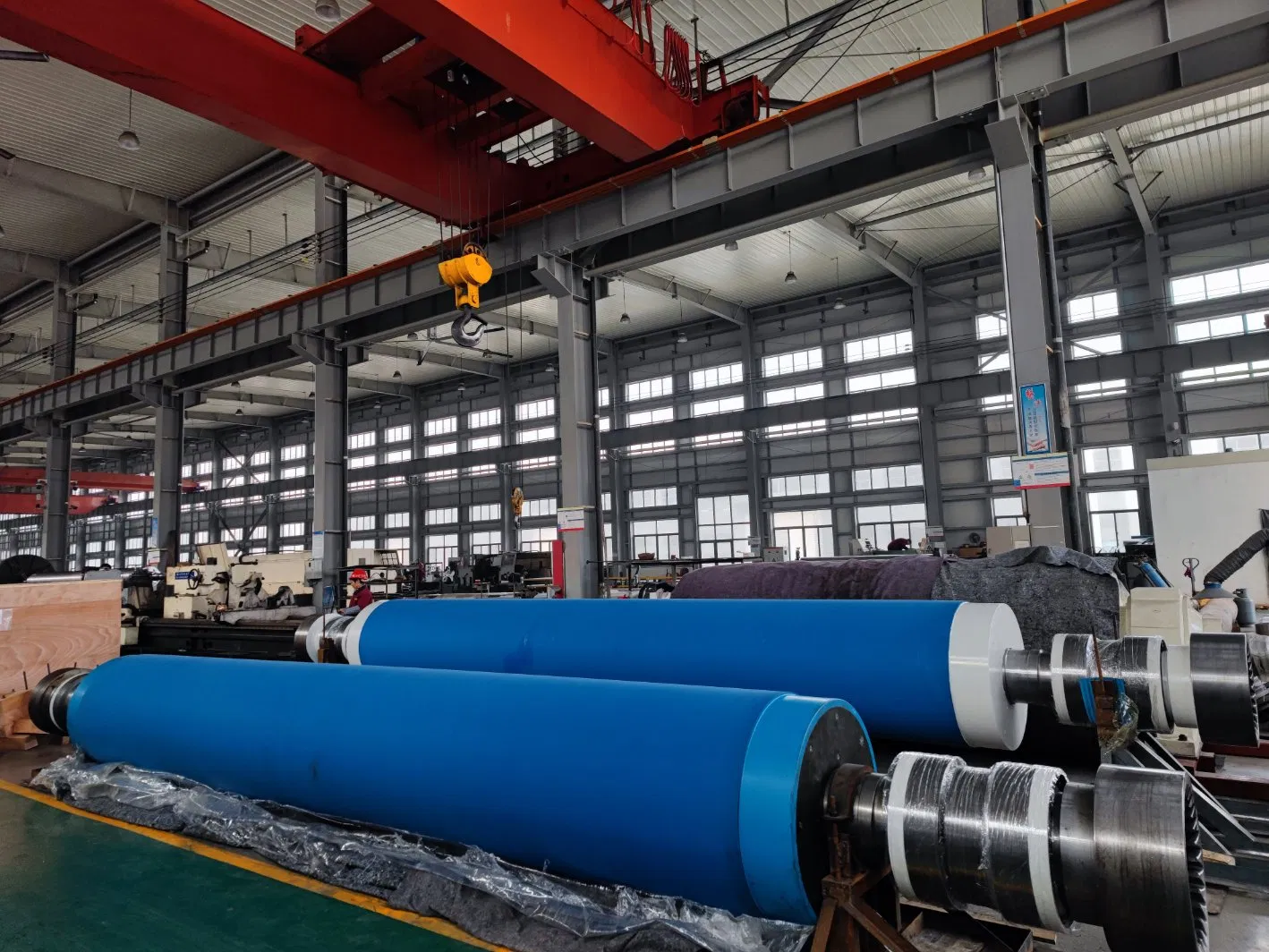

The Rise of Specialized Roll Coverings: Fine-Tuning for Specific Needs

As papermaking technology evolved, so did the demands placed on paper machine rolls. Different stages of the papermaking process require distinct roll properties. This led to the development of a vast array of specialized roll coverings, each designed for a specific function. Materials like polyurethane, composites, and ceramics offered tailored solutions for different paper grades, machine speeds, and operating conditions. Which type of roll covering is best suited for your specific papermaking needs?

The Impact of Polymers and Composites: A New Era of Performance

The development and application of synthetic polymers and composite materials revolutionized paper machine roll technology. These materials offer exceptional properties, including high wear resistance, chemical inertness, and the ability to be precisely engineered for specific applications. This has led to significant improvements in paper quality, machine efficiency, and overall productivity. The evolution of paper machine roll technology continues to be driven by the pursuit of longer-lasting and more efficient materials.

Modern Advancements: Precision Engineering and Smart Technologies

Today, the evolution of paper machine roll technology continues at a rapid pace. Advanced manufacturing techniques, including precision machining and coating processes, allow for the creation of highly specialized rolls with intricate designs. Furthermore, the integration of smart technologies, such as sensors and data analytics, is enabling real-time monitoring of roll performance and predictive maintenance, further optimizing efficiency and reducing downtime.

Roll Maintenance: Extending Lifespan and Optimizing Performance

Proper roll maintenance is crucial for maximizing the lifespan and performance of paper machine rolls. Regular cleaning, inspection, and timely repairs can prevent costly downtime and ensure consistent paper quality. Implementing a comprehensive roll maintenance program is essential for any paper mill seeking to optimize its operations.

Sustainability in Roll Technology: A Focus on the Future

The paper industry is increasingly focused on sustainability. This includes the development of more eco-friendly roll materials and manufacturing processes. The use of recycled materials, reduced energy consumption during production, and extended roll lifespan are all key areas of focus in the ongoing evolution of paper machine roll technology.

The Future of Paper Machine Roll Technology: Continued Innovation

What does the future hold for paper machine roll technology? Continued advancements in materials science, manufacturing techniques, and smart technologies will undoubtedly drive further innovation. We can expect to see even more specialized and efficient rolls, enabling higher machine speeds, improved paper quality, and reduced environmental impact.

Taking the Next Step: Optimizing Your Roll Performance

The evolution of paper machine roll technology has been a continuous journey of innovation and improvement. By understanding this evolution and embracing the latest advancements, paper mills can optimize their operations, enhance paper quality, and achieve greater sustainability. Consider evaluating your current roll technology and exploring the potential benefits of upgrading to more advanced solutions. Contact a specialist in paper machine roll technology to discuss your specific needs and discover how the right rolls can enhance your papermaking process.