As it turns out, the humble paper machine roll plays a vital role in paper production. But have you ever wondered what these rolls do and how they contribute to the process? In this complete guide, we'll explore the different types of paper machine rolls and their functions, so you can better understand this essential machinery.

Pressure Rolls: Keeping it Together

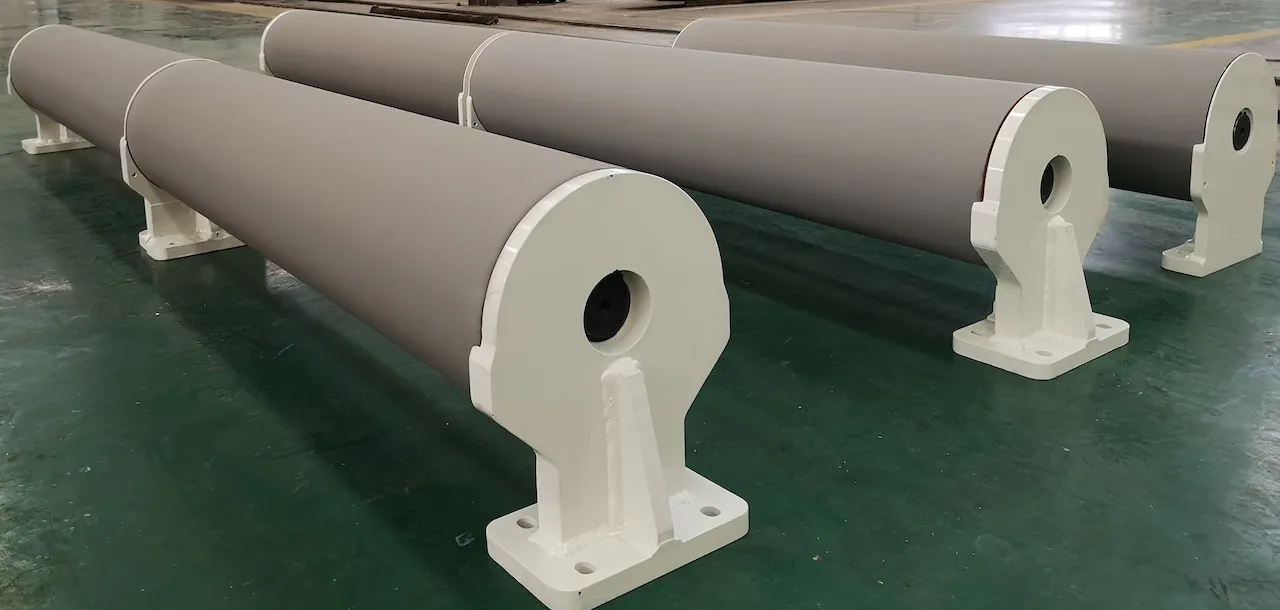

Pressure rolls, as the name suggests, apply pressure to the paper web to ensure proper adhesion and smoothness. They come in various shapes and sizes, including cylindrical, conical, or crowned, depending on the specific application. Some common types of pressure rolls include:

Choosing the Right Pressure Roll Materials

When selecting pressure rolls, it's crucial to consider the material composition. Common materials include:

- Rubber: Offers excellent grip and resilience, making it ideal for suction and nip rolls.

- Chrome-plated steel: Provides a smooth, hard surface perfect for transfer rolls and applications requiring high heat resistance.

- Ceramic-coated rolls: Combines durability and heat resistance with a non-stick surface, ideal for preventing paper build-up.

Drive Rolls: Keeping Things Moving

Drive rolls are responsible for propelling the paper web through the machine. They're typically larger and more robust than pressure rolls, and they're connected to the machine's main drive system. Some key types of drive rolls include:

- Dryer rolls: These steam-heated rolls help dry the paper web as it moves through the machine.

- Calendar rolls: Used to smooth and polish the paper surface, calendar rolls can be either hard or soft, depending on the desired finish.

- Tensioning rolls: These rolls maintain consistent tension in the paper web, ensuring even thickness and preventing wrinkles or tears.

Maximizing Drive Roll Efficiency

To get the most out of your drive rolls, consider the following tips:

- Regularly inspect roll surfaces for wear or damage, and replace them as needed.

- Ensure proper roll alignment to minimize friction and energy consumption.

- Monitor roll temperatures, especially in dryer rolls, to prevent overheating and paper damage.

Guide Rolls: Staying on Track

Guide rolls help keep the paper web aligned and on track as it moves through the machine. They're typically smaller than pressure or drive rolls and are often made of materials like rubber or plastic. Guide rolls can be either fixed or adjustable, allowing for precise control over paper web alignment.

Proper Guide Roll Placement

To ensure optimal paper web control, it's essential to position guide rolls correctly. Some guidelines for guide roll placement include:

- Place guide rolls near critical machine sections, such as turns or transitions, where misalignment is most likely to occur.

- Space guide rolls evenly throughout the machine to maintain consistent alignment and tension.

- Use adjustable guide rolls to fine-tune alignment and quickly address any issues that arise.

In Summary

Paper machine rolls are crucial components in the paper production process, each with its unique function and design. By understanding the different types of rolls and their applications, you can optimize your paper machine's performance and produce higher quality paper products. So the next time you see a roll of paper, take a moment to appreciate the complex machinery that made it possible!

Next Steps

Ready to dive deeper into the world of paper machines? Check out our other articles on paper machine maintenance, troubleshooting, and optimization. And don't hesitate to reach out to our team of experts for personalized advice and guidance.