The Crucial Role of Granite Roll Crown Control

Did you know that granite roll crown control plays a pivotal role in maintaining optimal nip pressure in your paper mill? In fact, even minor inconsistencies can lead to significant reductions in production efficiency. But here's the thing: many operators overlook this vital aspect of roll maintenance.

Understanding Nip Pressure

Nip pressure refers to the force exerted between two rolls when they come into contact with each other. In a paper mill, this pressure is responsible for dewatering the pulp and forming a continuous sheet of paper. Interestingly enough, achieving just the right amount of nip pressure can be a delicate balancing act.

The Impact of Roll Crown on Nip Pressure

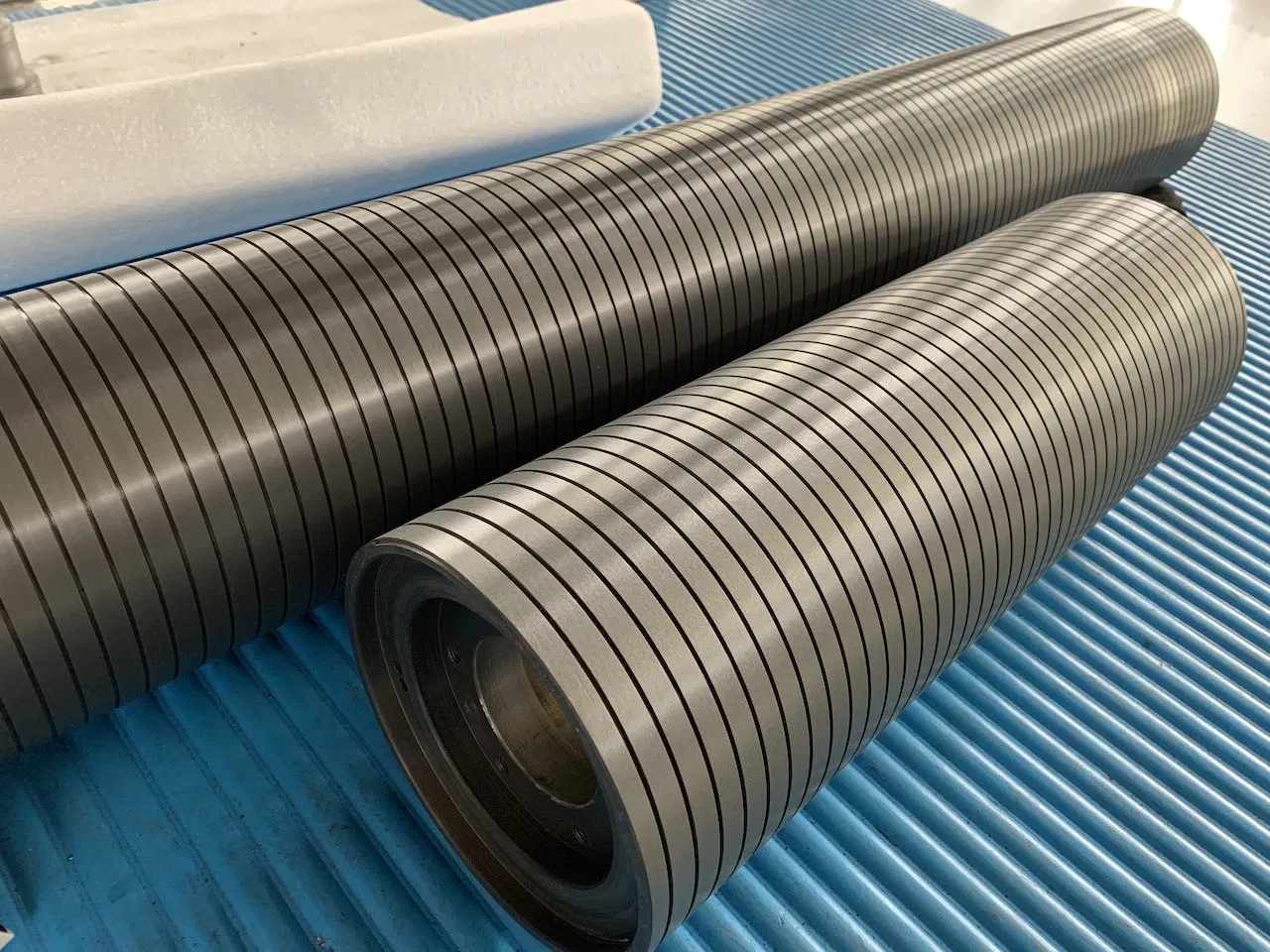

As it turns out, the crown of a granite roll has a direct impact on nip pressure. A crowned roll helps distribute pressure evenly across the width of the roll, ensuring consistent dewatering and sheet formation. However, if the roll crown becomes worn or uneven, it can lead to inconsistent nip pressure and decreased production efficiency.

Common Causes of Crown Distortion

So, what causes the crown of a granite roll to become distorted? There are several potential culprits, including:

Maintaining Optimal Nip Pressure

To maintain optimal nip pressure and maximize production efficiency, it's essential to keep your granite rolls in top condition. Here are some practical tips for doing just that:

Regular Inspection and Measurement

First and foremost, establish a routine inspection and measurement schedule for your granite rolls. This will help you identify any changes in roll crown or surface condition before they become problematic.

Precision Grinding and Profiling

When it's time to restore your rolls, opt for precision grinding and profiling services. These techniques can help you achieve the exact crown shape and surface finish needed to maintain optimal nip pressure.

Proactive Maintenance Strategies

Lastly, consider implementing proactive maintenance strategies to extend the life of your granite rolls and minimize the risk of crown distortion. This might include things like:

- Using protective coatings to shield rolls from chemical attack

- Implementing stress-relieving heat treatments to reduce the risk of mechanical distortion

- Monitoring roll deflection and adjusting operating parameters as needed

In Conclusion

In conclusion, granite roll crown control is a critical aspect of maintaining optimal nip pressure in your paper mill. By understanding the factors that affect roll crown and implementing proactive maintenance strategies, you can ensure consistent production efficiency and maximize the lifespan of your granite rolls. So, are you ready to take control of your roll crown and achieve optimal nip pressure?