Understanding the Role of Forming Rolls

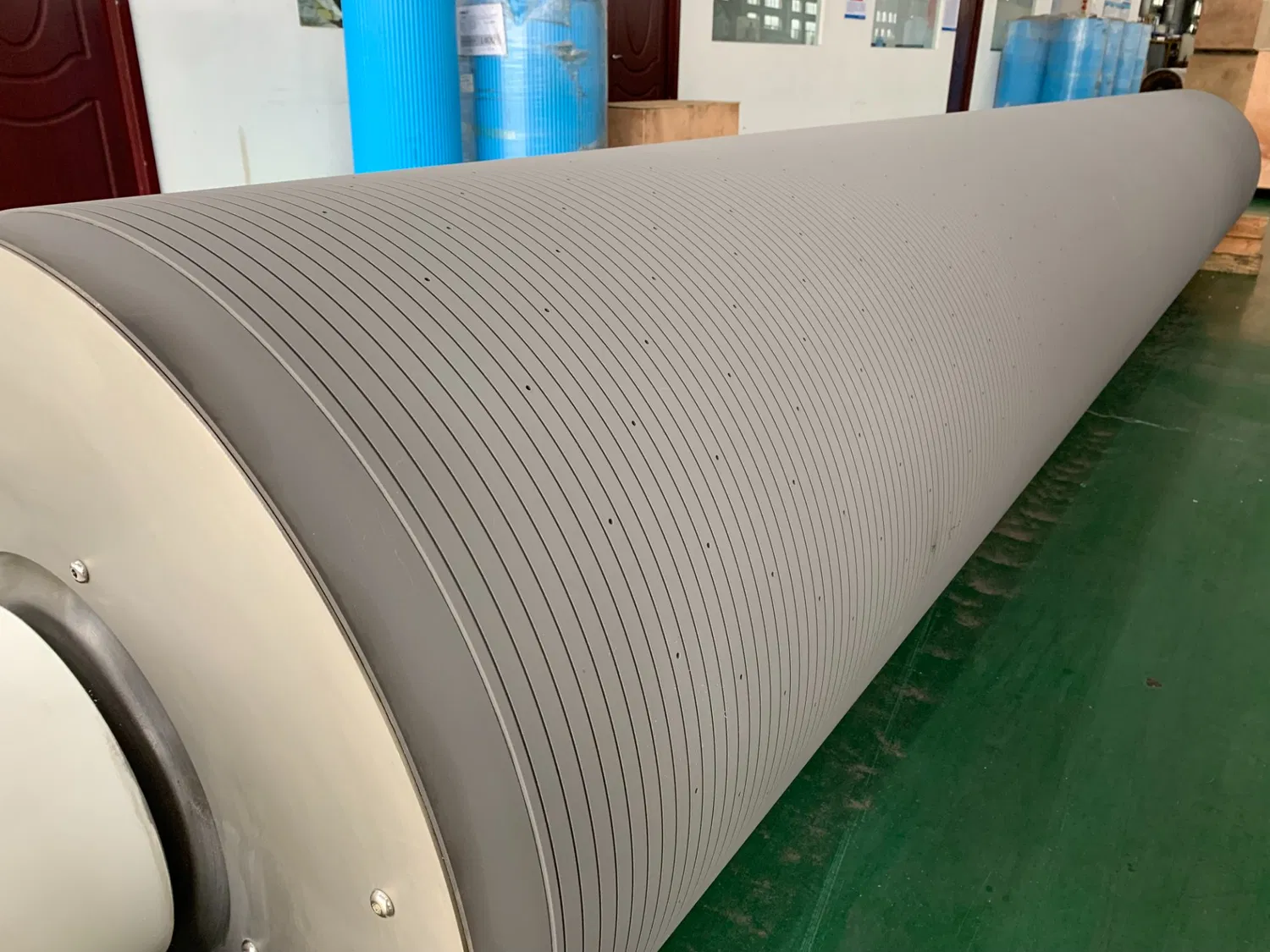

In the paper manufacturing process, forming rolls are critical components that contribute significantly to the final product's quality and consistency. Located at the wet end of a paper machine, these rolls help in dewatering the fiber suspension, forming a uniform sheet, and ensuring stability during the drying stage.

Quality and Consistency Factors

The design, materials, and maintenance of forming rolls greatly influence paper quality and consistency. Key factors include:

- Surface texture: A smooth roll surface promotes better water drainage and fiber alignment, resulting in enhanced paper smoothness and printing properties.

- Perforation pattern: The size, shape, and distribution of holes on the roll's surface impact dewatering efficiency and sheet formation.

- Material selection: Using materials with excellent wear resistance and corrosion protection prolongs roll life and maintains optimal performance.

- Proper maintenance: Regular inspections, cleaning, and repairs prevent issues like roll defects, which could negatively affect paper quality.

Improving Paper Quality with Advanced Forming Roll Technology

Modern forming roll technologies focus on improving paper quality and consistency through innovative designs and materials. Some examples include:

- Ceramic covers: Offer superior wear resistance and maintain a smooth surface for extended periods, ensuring consistent paper quality.

- Grooved designs: Enhance water removal and fiber orientation, leading to improved formation and stability in the paper sheet.

- Air-foil systems: These help in controlling the vacuum pressure within the roll, promoting more efficient dewatering and better paper formation.

The Importance of Regular Roll Maintenance

Routine maintenance is essential for preserving the performance and longevity of forming rolls. Regular inspections can identify potential issues early, preventing unscheduled downtime and maintaining paper quality consistency. Proper cleaning and repair practices also contribute to energy efficiency, reducing operational costs in the long run.

In conclusion, forming rolls significantly impact paper quality and consistency. By investing in advanced forming roll technology, optimizing designs, selecting appropriate materials, and adhering to regular maintenance schedules, paper manufacturers can ensure superior product quality, enhanced production efficiency, and reduced costs.