Web Breaks: Causes and Solutions

Web breaks are a frequent issue in paper production, leading to decreased efficiency and increased waste. Common causes include roll misalignment, inconsistent moisture levels, and excessive wear on the roll surfaces. To address these issues, regular maintenance and inspections are essential. Align rolls properly, monitor moisture levels, and replace worn roll covers when necessary.

Misalignment: Identifying and Correcting Roll Positioning

Misaligned rolls can result in poor paper quality, web breaks, and increased wear on the roll surfaces. Check for signs of misalignment, such as uneven paper thickness or wrinkles in the web. If misalignment is detected, adjust the roll positioning using shims, jack screws, or other adjustment mechanisms. Regularly inspect and adjust roll alignment to ensure optimal performance.

Vibration and Noise: Diagnosing and Resolving Problems

Excessive vibration and noise in paper machine rolls can lead to decreased productivity and increased roll wear. Identify the source of the vibration by inspecting roll bearings, couplings, and drive systems. Address any issues with worn or damaged components, and ensure proper lubrication and alignment. Balancing rolls can also help reduce vibration and noise.

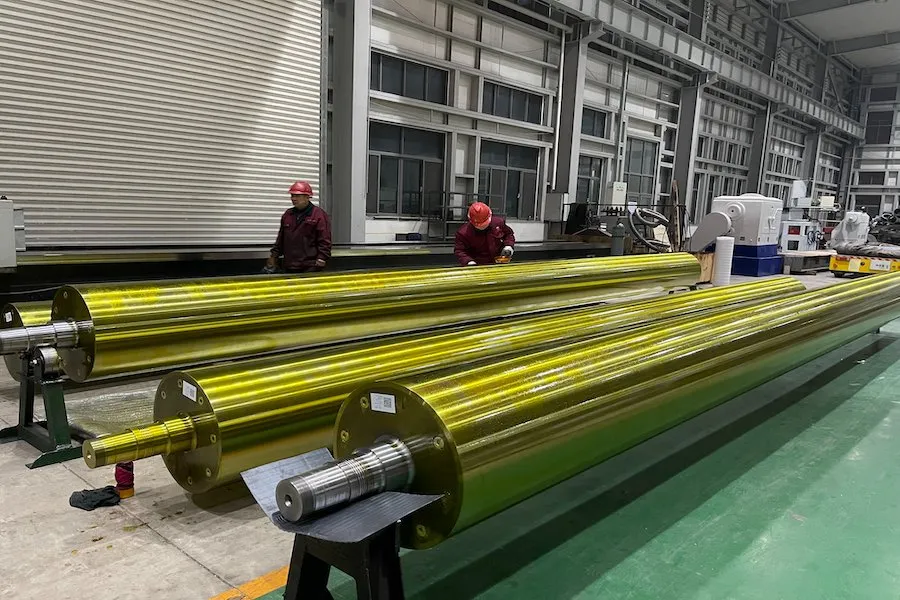

Improper Roll Covers: Selecting and Maintaining the Right Roll Covers

Choosing the right roll cover material is crucial for optimal paper machine performance. Consider factors such as paper type, machine speed, and operating conditions when selecting roll covers. Regularly inspect roll covers for wear and replace them as needed. Proper maintenance and timely replacement can significantly extend roll cover lifespan and improve paper quality.

Preventative Maintenance: Enhancing Paper Machine Roll Longevity

A comprehensive preventative maintenance program is essential for minimizing paper machine roll issues and maximizing productivity. Key components of such a program include regular inspections, lubrication, alignment checks, and roll cover replacement. By addressing potential problems proactively, mills can reduce downtime, improve paper quality, and lower overall maintenance costs.

Inspections

- Regularly inspect roll surfaces, bearings, and couplings for wear and damage

- Check roll alignment and adjust as necessary

- Monitor roll temperatures and address any overheating issues

Lubrication

- Ensure proper lubrication of roll bearings and couplings

- Monitor lubricant levels and replace as needed

- Use high-quality lubricants designed for paper machine applications

Alignment Checks

- Regularly check roll alignment and adjust as necessary

- Verify that roll gaps are consistent and appropriate for the paper type being produced

- Inspect drive systems for proper alignment and tension

Roll Cover Replacement

- Inspect roll covers regularly for wear and replace as needed

- Choose roll cover materials appropriate for the paper type and operating conditions

- Balance rolls after replacing covers to minimize vibration and improve paper quality