Understanding Paper Machine Rolls

Paper machine rolls play a vital role in the paper manufacturing process. They are responsible for various functions such as guiding, forming, pressing, drying, and calendaring the paper web. The quality and performance of these rolls significantly impact the final paper product's properties, including its strength, smoothness, and consistency.

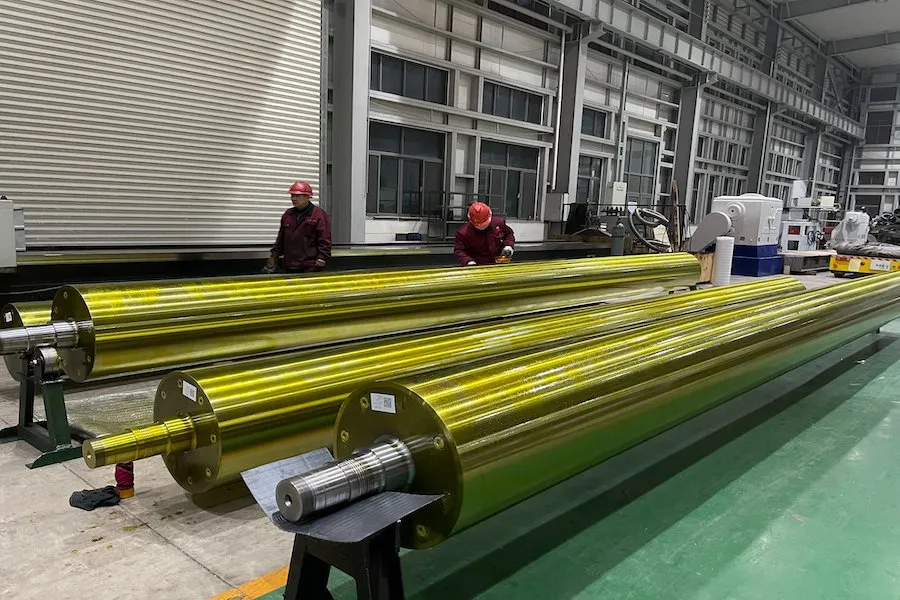

Importance of Roll Design and Materials

The design of paper machine rolls is crucial for achieving optimal paper quality and consistency. Modern roll designs focus on improving heat transfer, reducing wear and tear, and minimizing roll vibrations. Additionally, selecting the appropriate materials for the rolls is essential. For instance, chrome-plated rolls offer superior resistance to corrosion and wear, while cast iron rolls provide excellent heat transfer capabilities.

Enhancing Paper Quality with Proper Roll Maintenance

Regular maintenance of paper machine rolls is essential for ensuring their longevity and performance. Proper maintenance practices include cleaning, grinding, and balancing the rolls, as well as replacing worn-out parts. By adhering to a regular maintenance schedule, paper manufacturers can minimize downtime, reduce production costs, and produce high-quality, consistent paper products.

The Impact of Rolls on Paper Consistency

Paper consistency is a critical factor in determining the final product's quality. Inconsistent paper thickness can lead to issues such as uneven ink absorption, poor print quality, and reduced runnability. Paper machine rolls play a crucial role in maintaining paper consistency by providing uniform pressure and tension throughout the manufacturing process. A well-designed and maintained roll system can help ensure that the paper web is uniform in thickness, resulting in a high-quality, consistent final product.

Investing in High-Quality Paper Machine Rolls

Given the significant impact of paper machine rolls on paper quality and consistency, it is crucial for paper manufacturers to invest in high-quality rolls. By partnering with reputable roll suppliers and prioritizing regular maintenance, manufacturers can ensure that their rolls perform optimally and contribute to the production of superior paper products.