The Importance of Material Selection in Paper Machine Rolls

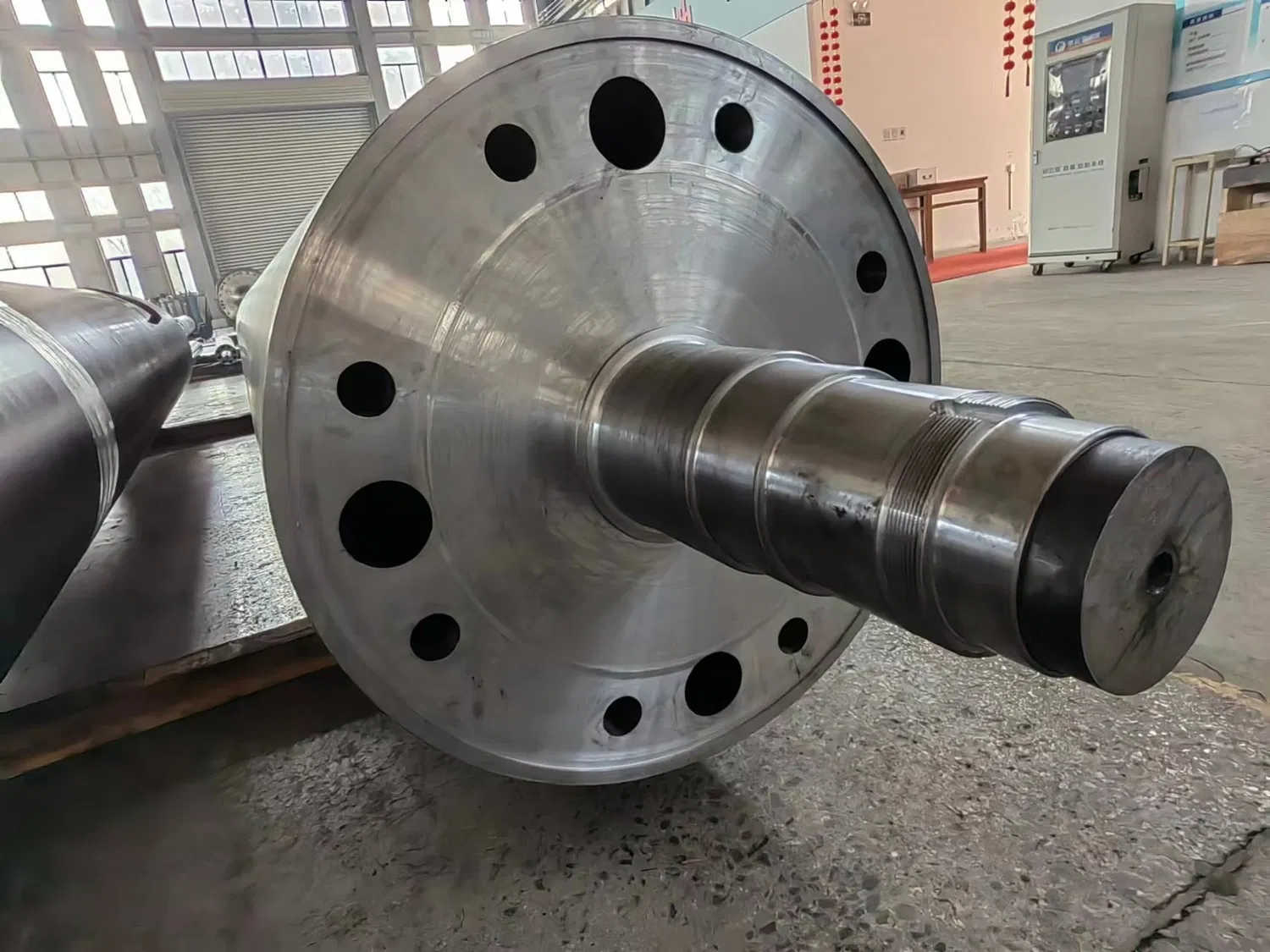

Paper machine rolls are a crucial component in the papermaking process, as they are responsible for guiding and supporting the paper web during production. The right material selection can significantly improve the rolls' performance and durability, ultimately leading to higher production efficiency.

Common Materials for Paper Machine Rolls

- Cast iron

- Steel

- Chromium-plated rolls

- Non-metallic materials (e.g., composite rolls)

Each material has its unique advantages, and the choice depends on the specific application and requirements of the papermaking process.

Surface Treatment Technologies for Paper Machine Rolls

Surface treatments play a vital role in enhancing the roll coverings' properties, such as wear resistance, heat resistance, and chemical resistance. These treatments can significantly extend the rolls' service life and improve their performance.

Popular Surface Treatment Technologies

- Chrome plating

- Thermal spray coatings

- Laser cladding

- Plasma-enhanced chemical vapor deposition (PECVD)

Selecting the appropriate surface treatment technology for paper machine rolls is essential in optimizing their performance and ensuring their longevity in the papermaking process.

Optimizing Roll Coverings for Enhanced Performance

Roll coverings are a critical aspect of paper machine rolls, as they determine the rolls' interaction with the paper web. Several factors must be considered when choosing the right roll covering, including the roll's function, the paper grade, and the operating conditions.

Types of Roll Coverings

- Rubber coverings

- Polymer coverings

- Ceramic coverings

- Composite coverings

By carefully selecting the right materials and surface treatment technologies for paper machine rolls, papermakers can optimize their equipment's performance and achieve higher production efficiency.