Introduction to Paper Machine Rolls

Paper machine rolls are essential components in the paper manufacturing process, contributing significantly to the final product's quality and efficiency. They come in various shapes, sizes, and materials, each serving a unique purpose in the production line. This article will delve into the different types of rolls, their functions, and their impact on the paper-making process.

Forming Rolls: Shaping the Paper

Forming rolls, also known as Fourdrinier rolls, play a crucial role in shaping the paper's structure. These rolls are responsible for creating a uniform and consistent paper web by distributing the pulp evenly on a moving wire. The forming process is critical, as it determines the paper's thickness, density, and overall quality. Forming rolls are typically made of cast iron, stainless steel, or other durable materials to withstand the harsh conditions of the paper-making process.

Drying Rolls: Removing the Moisture

After the paper has been formed, it must be dried to remove excess moisture. Drying rolls, often made of cast iron or steel, are heated and press against the paper web to evaporate the water. These rolls are usually arranged in a series, with each roll applying increasing pressure to ensure thorough drying. The drying process is essential, as it affects the paper's strength, stability, and appearance. Properly dried paper is less prone to wrinkles, curls, and other defects that can compromise its functionality and aesthetic appeal.

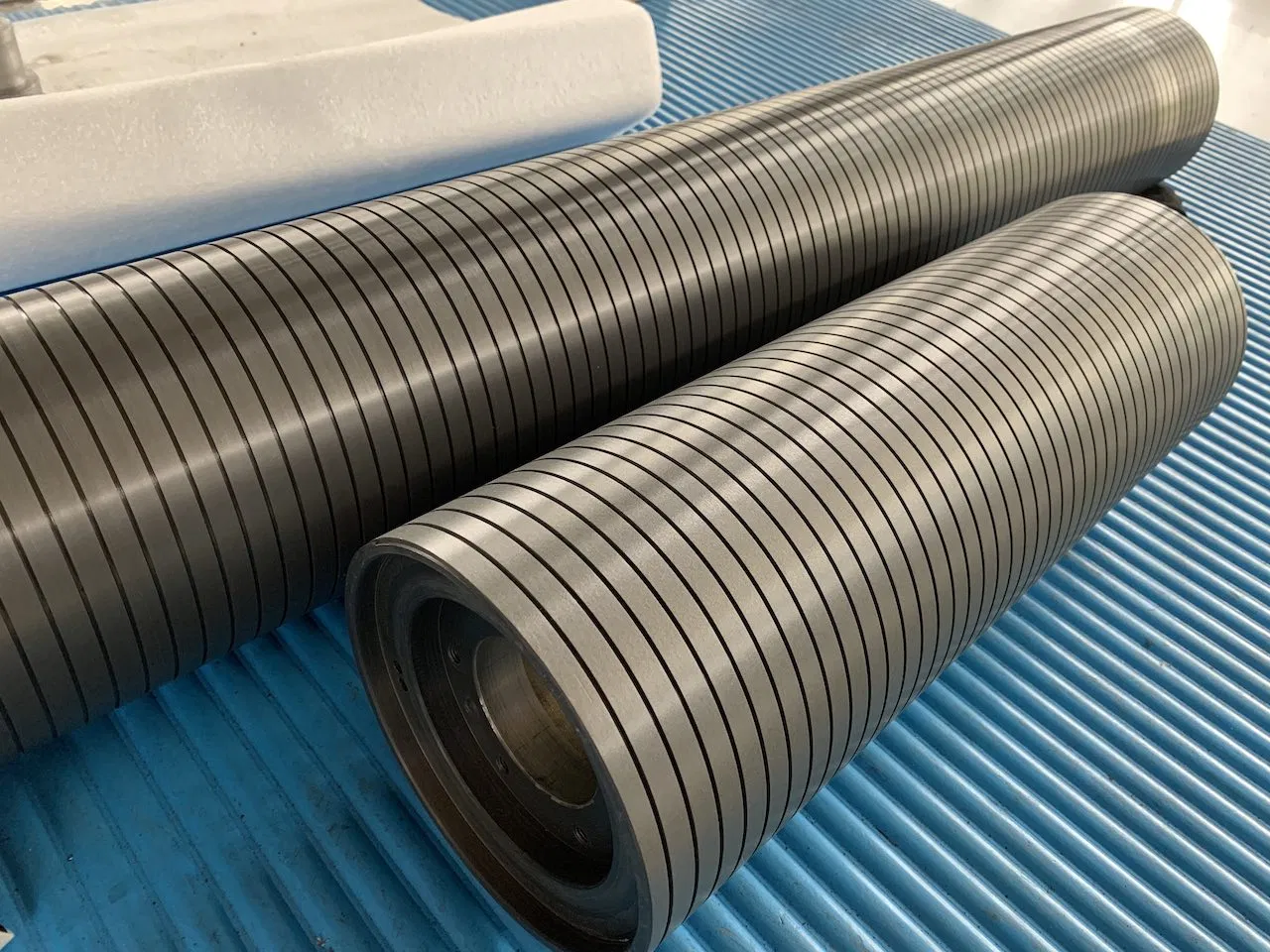

Calendar Rolls: Smoothing and Finishing

Calendar rolls are responsible for smoothing and finishing the paper's surface. These rolls are typically made of highly polished materials, such as steel or chrome, and are arranged in a series of alternating hard and soft rolls. As the paper passes through the calendar stack, it is subjected to intense pressure and heat, which compacts the fibers and gives the paper a smooth, glossy finish. Calendar rolls can also be used to impart specific textures or patterns to the paper, depending on the desired appearance and functionality.

Reel Rolls: Winding Up the Paper

Once the paper has been formed, dried, and finished, it must be wound onto reels for transportation and storage. Reel rolls are responsible for this crucial final step in the paper-making process. These rolls are typically made of steel or other durable materials and are designed to handle large rolls of paper with precision and efficiency. Proper reel winding is essential to ensure that the paper remains intact and free from damage during transportation and storage.

Conclusion

Paper machine rolls are indispensable components in the paper manufacturing process, serving various functions that contribute to the final product's quality and efficiency. From forming rolls that shape the paper's structure to reel rolls that wind up the finished product, each roll plays a critical role in the production line. Understanding the functions and importance of these rolls can help paper manufacturers optimize their processes and produce high-quality, consistent products that meet their customers' needs.