The Role of Paper Machine Rolls in Paper Production

In the paper production process, paper machine rolls play a crucial role in ensuring the efficient and high-quality production of paper. These rolls are responsible for guiding, supporting, and dewatering the paper web as it travels through the machine. The rolls are designed to work together in a coordinated manner to provide the necessary tension, compression, and drying required to produce the final paper product.

Different Types of Paper Machine Rolls

There are several different types of paper machine rolls, each with its own unique function and design. Some of the most common types of rolls include:

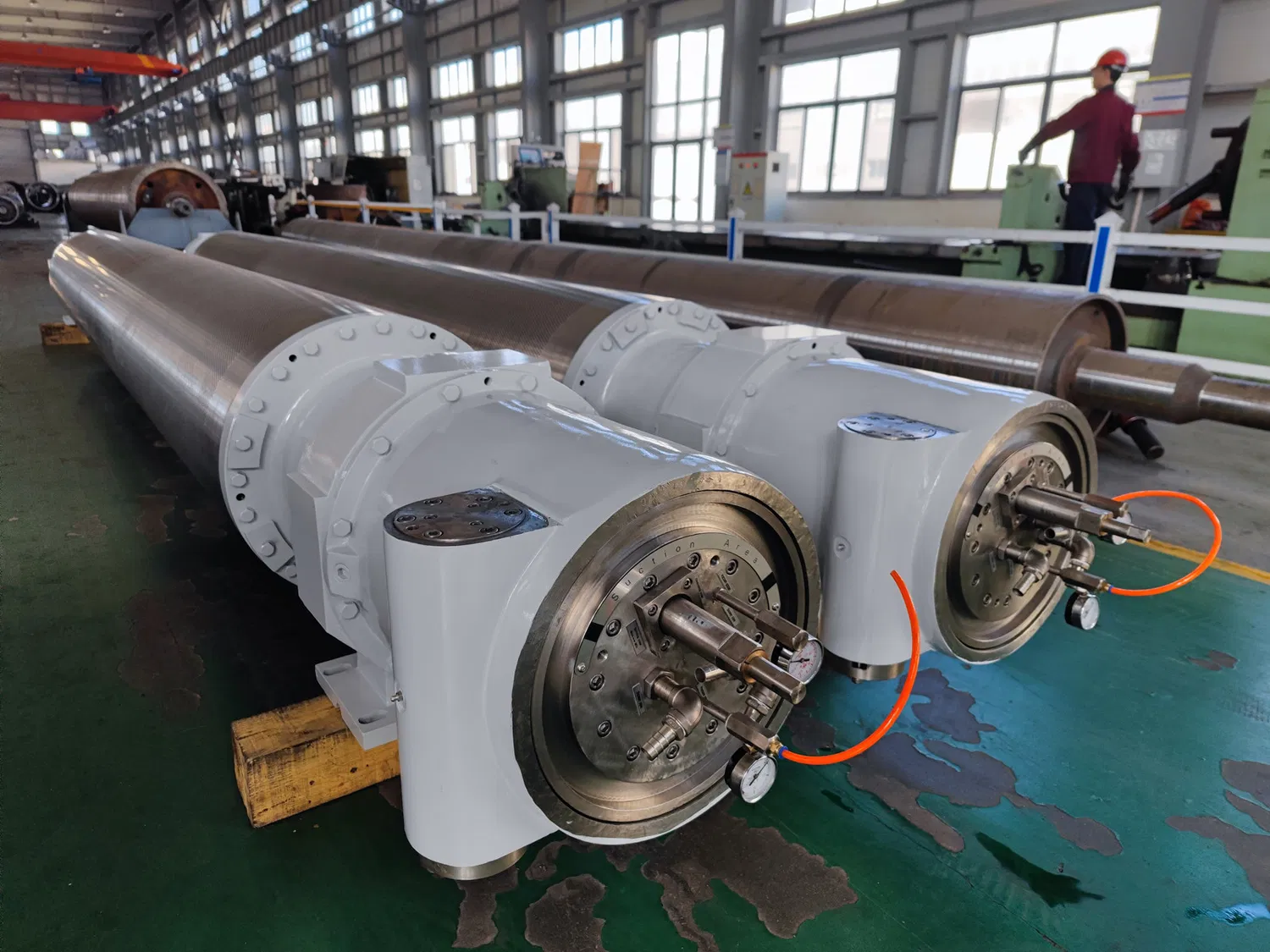

Press Rolls: These rolls are used to apply pressure to the paper web, helping to remove excess water and improve the stability of the paper.

Dryer Rolls: These rolls are responsible for removing the remaining water from the paper web, using heat and pressure to dry the paper.

Calendar Rolls: These rolls are used to smooth and finish the paper, providing a uniform surface and improving the paper's appearance and printability.

Guide Rolls: These rolls help to keep the paper web on track as it travels through the machine, ensuring that it stays aligned and does not deviate from the desired path.

The Working Principles of Paper Machine Rolls

Paper machine rolls operate on a variety of working principles, depending on their specific function and design. Some of the most common working principles include:

Compression: Press rolls use compression to apply pressure to the paper web, helping to remove excess water and improve stability.

Heat Transfer: Dryer rolls use heat transfer to remove the remaining water from the paper web, using steam or hot air to dry the paper.

Friction: Calendar rolls use friction to smooth and finish the paper, applying pressure and heat to create a uniform surface.

Tension Control: Guide rolls use tension control to keep the paper web on track, adjusting the tension as needed to ensure proper alignment.

The Importance of Proper Roll Maintenance and Care

Proper maintenance and care of paper machine rolls is essential to ensure their optimal performance and longevity. Regular inspections, cleaning, and lubrication can help to prevent damage and wear, while timely repairs and replacements can prevent unplanned downtime and reduce overall maintenance costs. Additionally, using high-quality roll materials and coatings can improve roll performance and extend their service life.

Conclusion

In conclusion, paper machine rolls play a crucial role in the paper production process, providing the necessary guidance, support, and dewatering required to produce high-quality paper. By understanding the different types of rolls and their working principles, as well as the importance of proper maintenance and care, manufacturers can ensure efficient and effective paper production while minimizing downtime and maintenance costs.