The Importance of Wear Resistance in Paper Machine Rolls

In the paper manufacturing industry, wear resistance is a crucial factor in maintaining the optimal performance of paper machine rolls. The constant friction and abrasion caused by the papermaking process can result in significant wear and tear, leading to decreased efficiency and increased downtime. By implementing effective methods to improve wear resistance, manufacturers can extend the lifespan of their equipment and reduce maintenance costs.

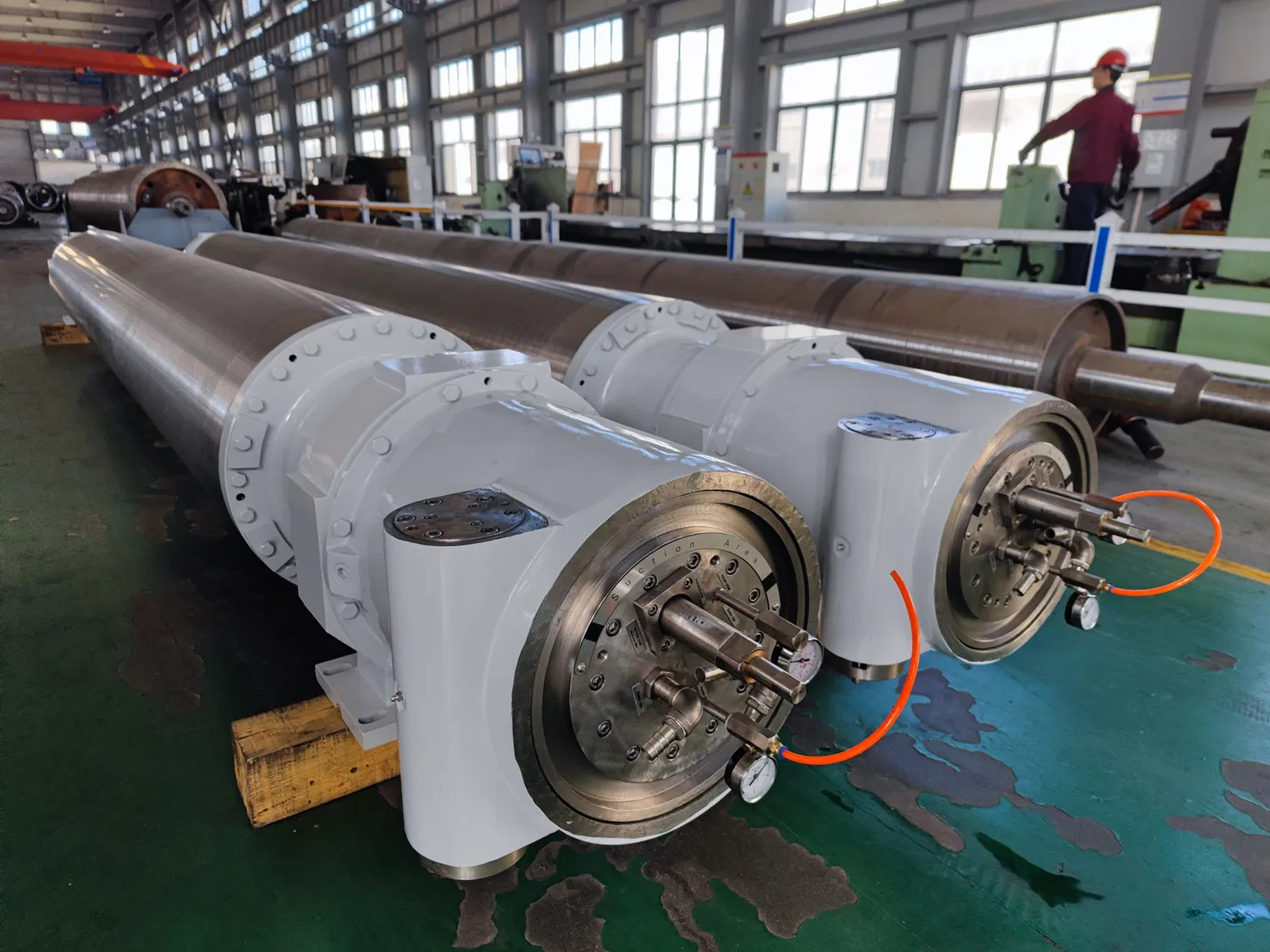

Selecting the Right Material for Roll Surfaces

Choosing the appropriate material for paper machine roll surfaces is a key factor in enhancing wear resistance. Common materials used for roll surfaces include cast iron, hard-faced steel, and chrome-plated rolls. Each material has its unique properties and advantages, and selecting the right one depends on the specific application, roll type, and operating conditions.

Surface Treatments for Enhanced Wear Resistance

Surface treatments are an effective way to improve the wear resistance of paper machine rolls. These treatments alter the surface properties of the roll, making it more resilient to abrasion and wear. Some common surface treatments include:

- Hardfacing: Depositing wear-resistant alloys on the roll surface using welding or thermal spraying

- Shot peening: Bombarding the roll surface with small metal balls to create a compressive residual stress layer, improving fatigue strength and wear resistance

- Nitriding: Introducing nitrogen atoms into the roll surface to form a hard, wear-resistant case

Advanced Coatings for Improved Performance

In addition to surface treatments, advanced coatings can also be applied to paper machine rolls to further enhance their wear resistance. These coatings provide an additional protective layer on the roll surface, reducing friction, and minimizing wear. Some examples of advanced coatings include:

- Polytetrafluoroethylene (PTFE): A low-friction, non-stick coating that provides excellent wear resistance

- Chromium oxide (Cr2O3): A hard, wear-resistant coating that can withstand high temperatures and pressures

- Diamond-like carbon (DLC): An ultra-hard, low-friction coating that offers superior wear resistance and corrosion protection

Regular Maintenance and Inspections

Regular maintenance and inspections are essential for ensuring the long-term performance and wear resistance of paper machine rolls. By identifying and addressing issues early, manufacturers can prevent excessive wear, reduce downtime, and extend the lifespan of their equipment. This includes regular cleaning, lubrication, and monitoring of roll surfaces, as well as periodic reconditioning or replacement of worn rolls.