Introduction

The paper industry has come a long way in recent years, with domestic paper roll manufacturing experiencing significant progress and breakthroughs. From new technologies and processes to sustainable practices and market trends, there is a lot to explore in this exciting field.

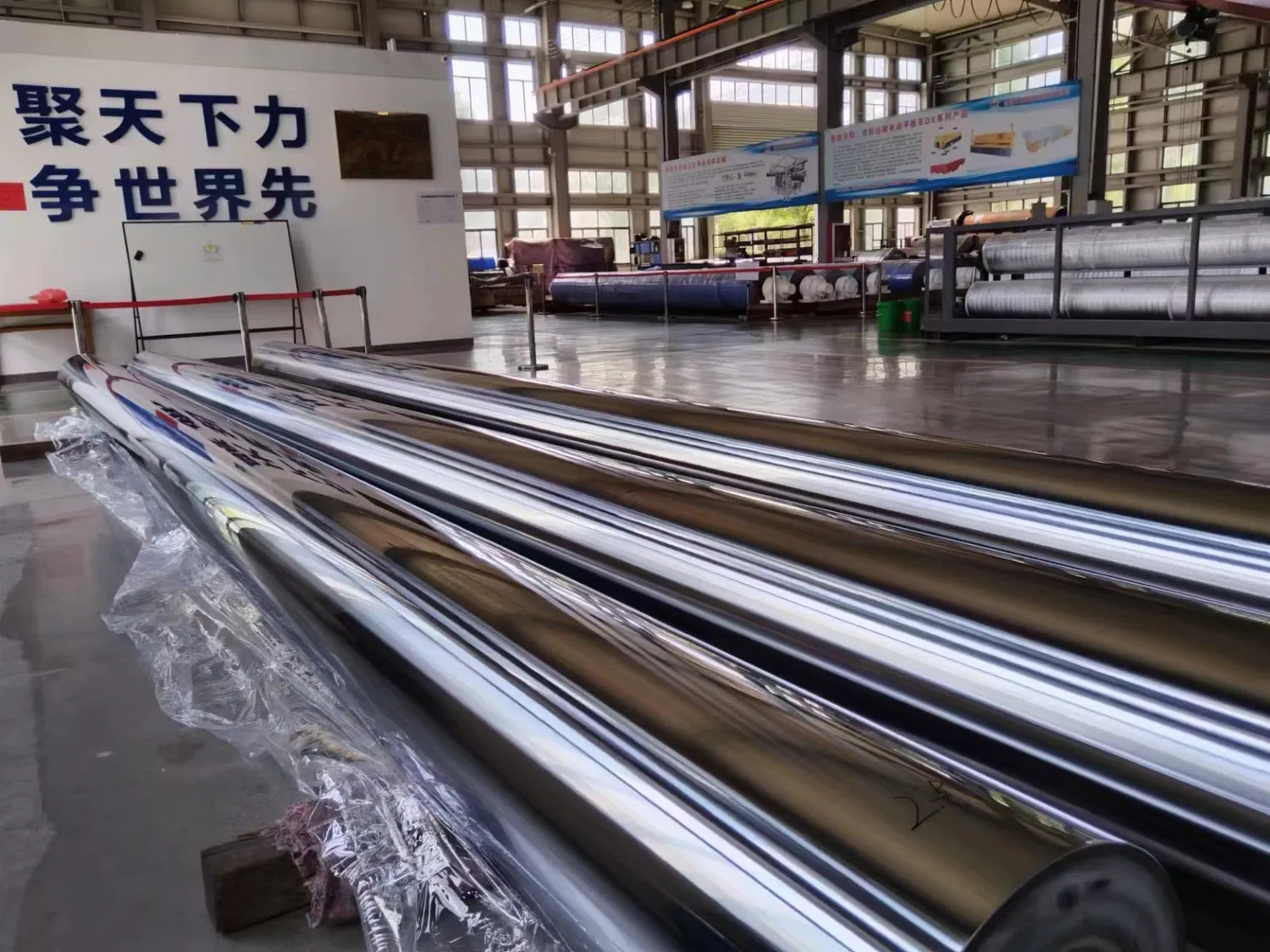

New Technologies and Processes

One of the most notable advancements in domestic paper roll manufacturing is the use of new technologies and processes. For example, some manufacturers are now using advanced automation systems to improve efficiency and reduce waste. Others are experimenting with new materials and coatings to enhance the performance and durability of their products.

Improved Efficiency and Reduced Waste

One of the key benefits of new technologies and processes in paper roll manufacturing is improved efficiency and reduced waste. By automating key processes, manufacturers can reduce the amount of time and resources required to produce each roll of paper. This not only helps to improve profitability but also reduces the environmental impact of the manufacturing process.

Enhanced Performance and Durability

Another benefit of new technologies and materials in paper roll manufacturing is enhanced performance and durability. For example, some manufacturers are now using special coatings to improve the moisture resistance and strength of their products. This can help to extend the lifespan of the paper rolls and reduce the need for frequent replacements.

Sustainable Practices

In addition to new technologies and processes, many domestic paper roll manufacturers are also focusing on sustainability. This includes reducing energy consumption, water usage, and waste production, as well as sourcing materials from sustainable sources.

Energy Efficiency and Conservation

One of the key areas of focus for sustainable paper roll manufacturing is energy efficiency and conservation. By using more energy-efficient equipment and processes, manufacturers can reduce their carbon footprint and save money on energy costs. This is not only good for the environment but also helps to improve profitability and competitiveness.

Water Conservation and Waste Reduction

Another important area of focus for sustainable paper roll manufacturing is water conservation and waste reduction. By using water-efficient processes and recycling water where possible, manufacturers can significantly reduce their water usage. Additionally, by implementing waste reduction strategies such as lean manufacturing and recycling programs, manufacturers can reduce the amount of waste generated during the manufacturing process.

Market Trends and Opportunities

Finally, it's important to consider the market trends and opportunities in domestic paper roll manufacturing. With increasing demand for sustainable and high-performance products, there are many opportunities for manufacturers to differentiate themselves and gain a competitive advantage.

Sustainable Products and Practices

One of the key market trends in paper roll manufacturing is the demand for sustainable products and practices. As consumers become more environmentally conscious, they are looking for products that are produced in a sustainable and responsible manner. By focusing on sustainability, manufacturers can tap into this growing market and meet the needs of environmentally-conscious consumers.

High-Performance Products

Another market trend in paper roll manufacturing is the demand for high-performance products. With advancements in technology and materials, manufacturers are now able to produce paper rolls that offer improved performance and durability. By focusing on high-performance products, manufacturers can differentiate themselves from competitors and meet the needs of demanding customers.