Introduction

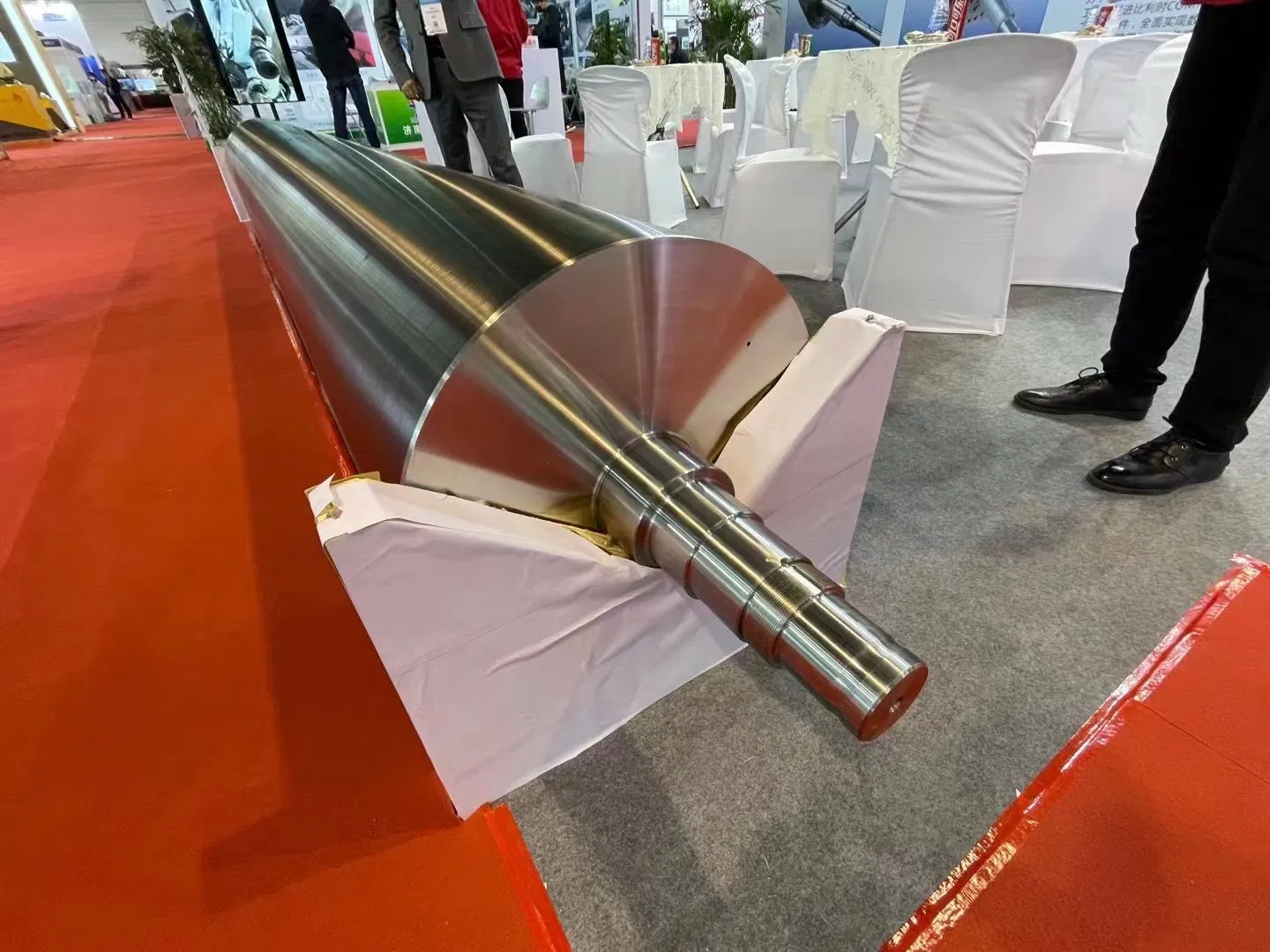

Paper machine rolls are an essential part of the paper manufacturing process. However, they are prone to various problems that can disrupt the production process and lead to costly downtime. In this article, we will discuss some of the most common paper machine roll problems and their troubleshooting solutions.

Roll Wear and Corrosion

Roll wear and corrosion are common problems that can affect the performance of paper machine rolls. Wear can cause the roll surface to become rough, which can lead to sheet defects, while corrosion can cause the roll to weaken and fail prematurely. To prevent these issues, it is recommended to regularly inspect the rolls for signs of wear and corrosion and to replace them as needed.

Troubleshooting Roll Wear and Corrosion

To troubleshoot roll wear and corrosion, it is important to identify the root cause of the problem. This can be done by analyzing the roll surface for signs of wear patterns or by testing the roll material for corrosion resistance. Once the root cause has been identified, appropriate measures can be taken to prevent further wear and corrosion, such as using harder roll materials or applying corrosion-resistant coatings.

Roll Vibration and Chatter

Roll vibration and chatter are other common problems that can affect the performance of paper machine rolls. Vibration can cause the roll to move excessively, leading to sheet defects and increased wear, while chatter can cause the roll to produce a loud noise and create visible marks on the paper sheet. To prevent these issues, it is recommended to regularly balance the rolls and to ensure that they are properly aligned.

Troubleshooting Roll Vibration and Chatter

To troubleshoot roll vibration and chatter, it is important to identify the source of the problem. This can be done by measuring the roll vibration and analyzing the data to identify any patterns or anomalies. Once the source of the problem has been identified, appropriate measures can be taken to address it, such as balancing the roll or adjusting the alignment.

Roll Bearing Failure

Roll bearing failure is a common problem that can cause paper machine rolls to seize up or fail prematurely. Bearing failure can be caused by a variety of factors, including contamination, lubrication failure, and excessive load or speed. To prevent bearing failure, it is recommended to regularly inspect and maintain the bearings and to ensure that they are properly lubricated.

Troubleshooting Roll Bearing Failure

To troubleshoot roll bearing failure, it is important to identify the root cause of the problem. This can be done by inspecting the bearings for signs of wear or damage and by analyzing the lubrication system for any issues. Once the root cause has been identified, appropriate measures can be taken to address it, such as replacing the bearings or repairing the lubrication system.

Conclusion

In conclusion, paper machine roll problems can cause significant downtime and increase production costs. Regular maintenance and troubleshooting can help prevent these issues and ensure that the rolls are performing optimally. By following the tips outlined in this article, paper manufacturers can minimize roll problems and maximize their production efficiency.