The Importance of Dynamic Balancing

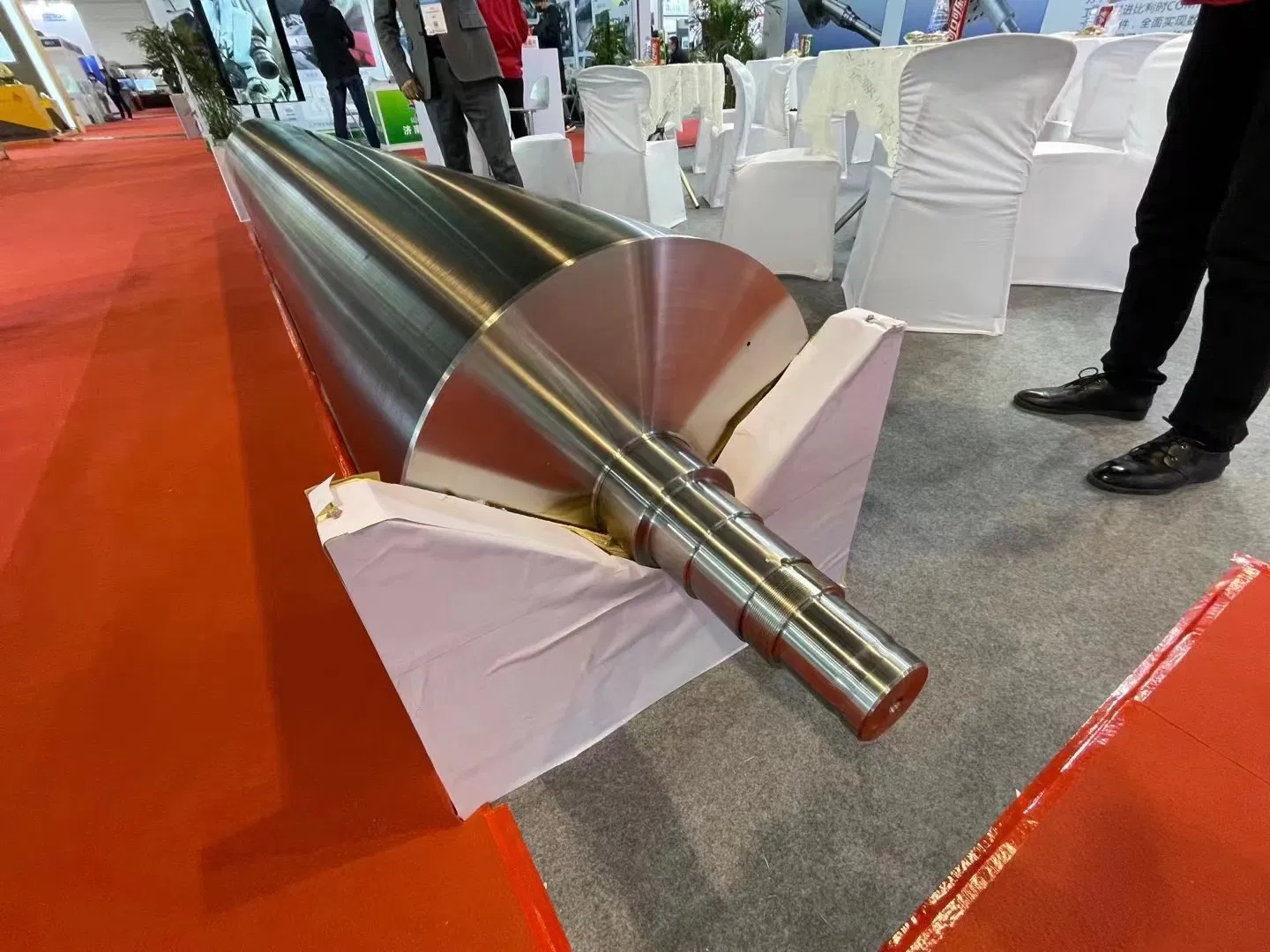

Dynamic balancing is a crucial aspect of maintaining paper machine rolls. This process ensures that rolls rotate evenly and smoothly, reducing vibration and wear. Properly balanced rolls not only improve the overall performance of the machine but also extend its lifespan and minimize costly downtime.

Factors Affecting Roll Balance

Several factors can affect the balance of paper machine rolls. These include manufacturing defects, wear and tear, and the accumulation of deposits on roll surfaces. Regular inspections and maintenance can help identify and address these issues before they cause significant problems.

How Dynamic Balancing Works

Dynamic balancing involves measuring the vibration of a rotating roll and then adding or removing weight to counteract any imbalance. This process is typically performed using specialized equipment, such as balancing machines or vibration analyzers. The goal is to achieve a state of "dynamic equilibrium" where the roll's center of gravity remains constant as it rotates.

Benefits of Dynamic Balancing

- Improved machine performance: Properly balanced rolls reduce vibration and improve the stability of the paper web, resulting in higher production speeds and better product quality.

- Increased roll lifespan: Reducing wear and tear through dynamic balancing extends the life of rolls, minimizing the need for frequent replacements.

- Reduced downtime: By addressing imbalances before they cause damage, dynamic balancing helps prevent unplanned shutdowns and minimizes maintenance time.

Best Practices for Dynamic Balancing

To ensure optimal performance and minimize downtime, follow these best practices for dynamic balancing:

Regular Inspections and Maintenance

Establish a regular schedule for inspecting and balancing paper machine rolls. This will help identify potential issues early and prevent them from causing significant problems.

Use Specialized Equipment

Invest in high-quality balancing machines and vibration analyzers to accurately measure and correct roll imbalances.

Training and Expertise

Ensure that staff responsible for dynamic balancing are properly trained and have the necessary expertise. This will help ensure that the process is performed correctly and effectively.

Documentation and Record-Keeping

Maintain detailed records of balancing activities, including measurements, adjustments, and equipment used. This information can be invaluable in identifying trends and optimizing maintenance strategies.

Conclusion

Dynamic balancing is an essential aspect of maintaining paper machine rolls. By following best practices and investing in the right equipment and expertise, manufacturers can improve performance, increase roll lifespan, and minimize costly downtime. Don't overlook this critical component of paper machine maintenance.