The Importance of Press Dewatering

Press dewatering is a critical process in many industries, including paper and pulp production, wastewater treatment, and mineral processing. By removing excess water, press dewatering helps to improve the efficiency and quality of downstream processes, reduce energy consumption, and lower production costs. One way to optimize press dewatering is by using grooved and blind drilled rolls.

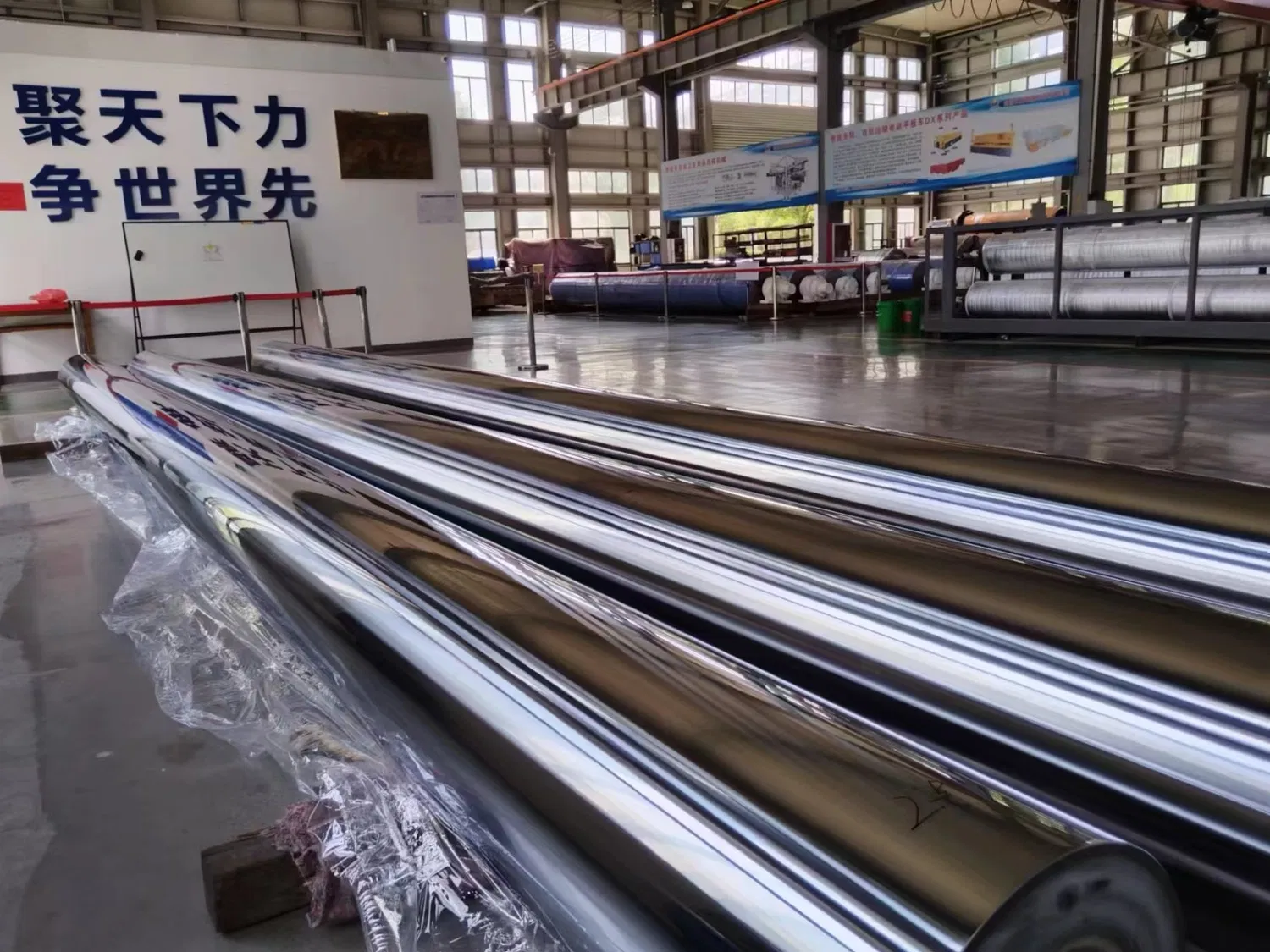

Grooved Rolls: Enhancing Dewatering Efficiency

Grooved rolls are rolls that have been machined with a pattern of grooves or channels on their surface. These grooves help to increase the contact area between the roll and the material being dewatered, which in turn improves the efficiency of the dewatering process. Grooved rolls are particularly useful in applications where the material being dewatered has a high water content or is difficult to dewater.

Choosing the Right Groove Pattern

When selecting grooved rolls for your press dewatering application, it is important to choose the right groove pattern. The groove pattern should be designed to optimize the flow of water and solids through the roll, while minimizing the risk of clogging or plugging. Common groove patterns include herringbone, chevron, and spiral grooves.

Blind Drilled Rolls: Maximizing Dewatering Capacity

Blind drilled rolls are rolls that have been drilled with a series of blind holes, or holes that do not go all the way through the roll. These holes create additional channels for water to flow through, which helps to increase the dewatering capacity of the roll. Blind drilled rolls are particularly useful in applications where high dewatering capacity is required, such as in the production of paper or board.

Designing Blind Drilled Rolls for Your Application

When designing blind drilled rolls for your press dewatering application, it is important to consider factors such as the size and shape of the holes, the spacing between the holes, and the number of rows of holes. The design of the blind drilled roll should be optimized to achieve the desired dewatering capacity, while minimizing the risk of clogging or plugging. It is also important to consider the material properties of the roll, such as its hardness and wear resistance.

Benefits of Using Grooved and Blind Drilled Rolls

Using grooved and blind drilled rolls can offer a number of benefits for press dewatering applications, including:

- Improved dewatering efficiency and capacity

- Reduced energy consumption and production costs

- Improved product quality and consistency

- Reduced risk of clogging or plugging

- Increased roll life and reduced maintenance costs