Understanding Paper Machine Rolls

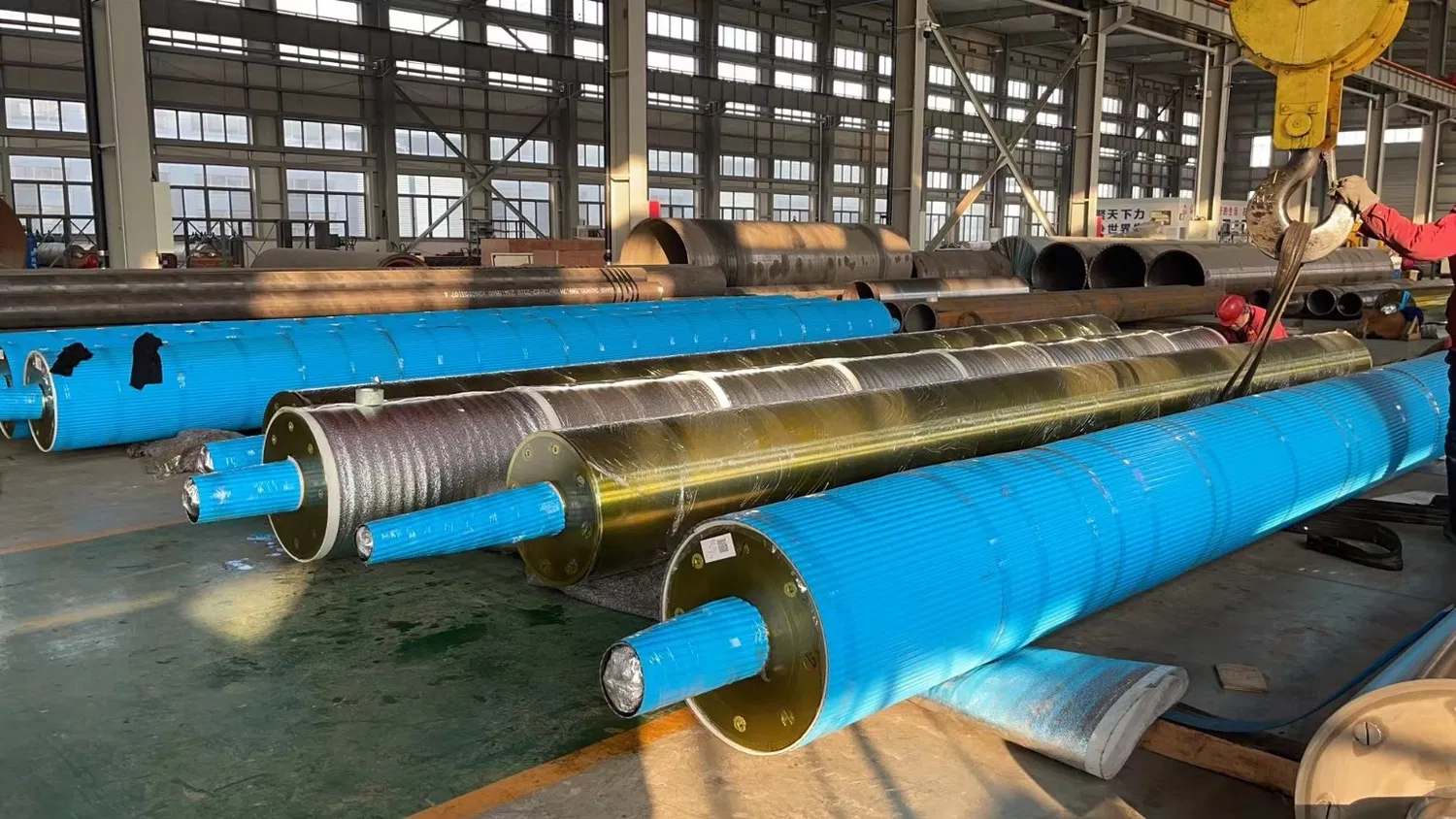

Paper machine rolls are essential components in the paper manufacturing process. They play a critical role in the formation, pressing, drying, and calendaring of paper. Common roll types include suction rolls, press rolls, and calendar rolls. Identifying and addressing issues promptly is crucial for maintaining product quality and minimizing downtime.

Vibration and Noise Problems

Vibration and excessive noise are common issues with paper machine rolls. Imbalance, misalignment, or loose bearings can cause these problems. To troubleshoot, first check for any visible signs of wear or damage. Ensure bearings are properly lubricated and adjusted. Use vibration analysis tools to diagnose more complex issues and balance rolls as needed.

Misalignment and Uneven Web

Misaligned rolls can lead to uneven paper webs, causing wrinkles, creases, or other defects. Inspect rolls for proper alignment and adjust as necessary. Regularly check roll surfaces for wear or damage that may contribute to misalignment. Consider using roll positioning systems to maintain precise alignment and improve paper quality.

Wear and Corrosion

Paper machine rolls are subject to wear and corrosion due to the harsh conditions of the papermaking process. Worn rolls can result in decreased paper quality, reduced efficiency, and increased downtime. Regularly inspect roll surfaces for signs of wear or corrosion. Replace or refurbish rolls as needed to ensure optimal performance.

Preventative Maintenance

Implementing a preventative maintenance program is crucial for minimizing roll issues and extending roll life. Schedule regular inspections and maintenance tasks, including cleaning, lubrication, and adjustments. Keep detailed records of roll performance and maintenance history to identify trends and address potential problems proactively.

Conclusion

Addressing common paper machine roll issues promptly is essential for maintaining product quality and minimizing downtime. By understanding the root causes of these problems and following best practices for roll maintenance, papermakers can ensure optimal performance and extend the life of their equipment.