The Essential Role of Paper Machine Rolls

In the highly competitive and dynamic paper industry, the importance of paper machine rolls cannot be overstated. These rolls play a crucial role in the manufacturing process, ensuring consistent product quality, minimizing downtime, and maximizing efficiency. As the paper industry continues to evolve, the demand for advanced roll technology becomes increasingly evident.

Types of Paper Machine Rolls

There are several types of paper machine rolls, each with unique functions and applications. Some of the most common types include press rolls, calendar rolls, guide rolls, and drying cylinders. Each roll type is specifically designed to meet the demands of various stages in the paper production process, contributing to the overall performance and efficiency of the machine.

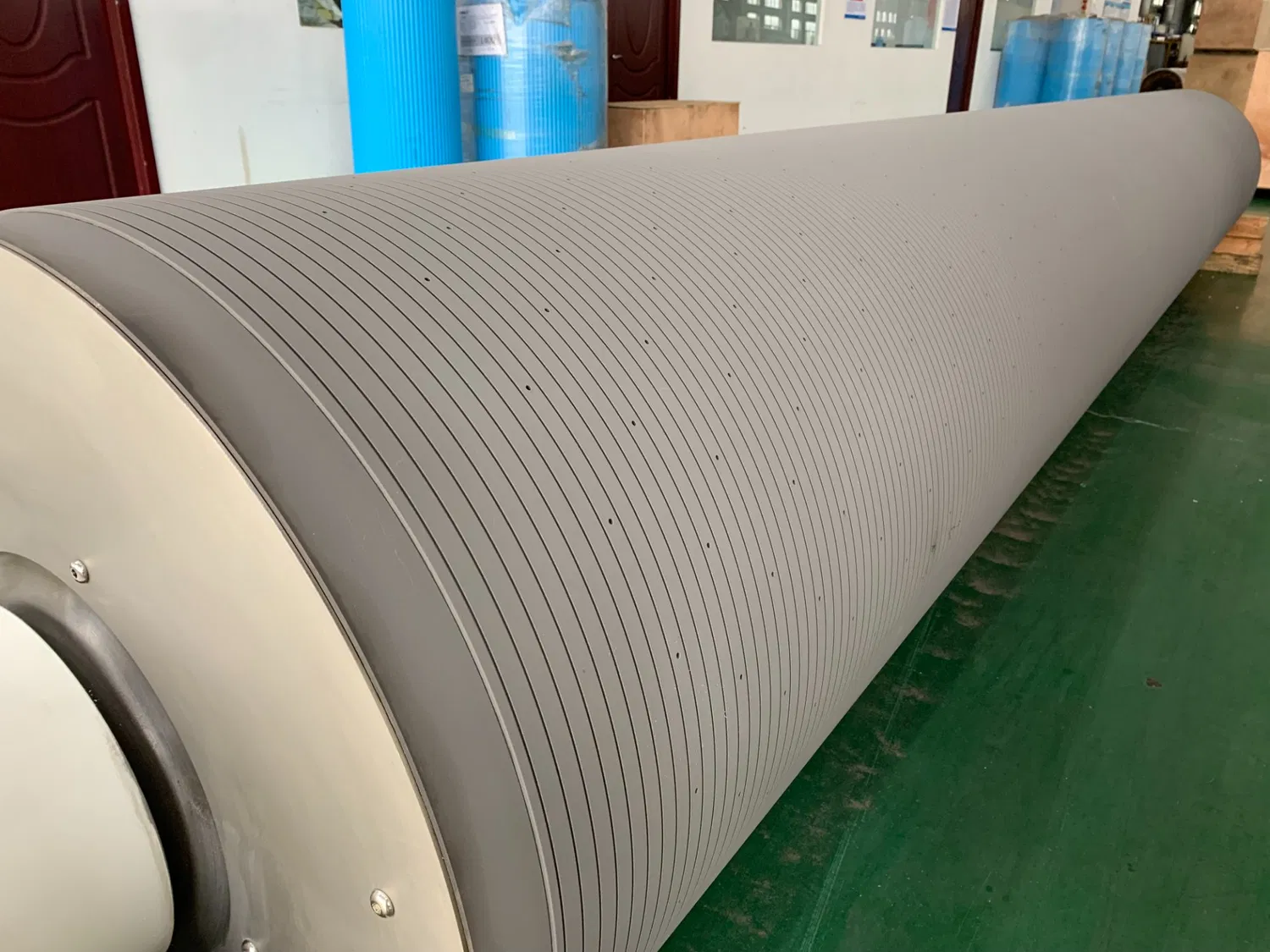

Press Rolls

Press rolls are responsible for removing water from the paper sheet, which is essential for achieving the desired thickness and density. These rolls apply pressure to the paper, facilitating water removal and promoting fiber-to-fiber bonding. Advanced press roll technology, such as grooved or patterned roll surfaces, can further enhance dewatering capabilities and improve paper quality.

Calendar Rolls

Calendar rolls are used to smooth and compact the paper surface, enhancing its appearance, printability, and strength. By applying precise and consistent pressure, calendar rolls help create a uniform finish that meets the exacting standards of modern paper products.

Guide Rolls

Guide rolls ensure proper paper alignment and tension control throughout the manufacturing process. These rolls play a critical role in maintaining product quality and minimizing waste by preventing paper misalignment and wrinkling.

Drying Cylinders

Drying cylinders remove the remaining moisture from the paper sheet, preparing it for further processing or finishing. These cylinders are typically heated, using steam or hot air, to facilitate rapid and efficient drying. Innovations in drying cylinder technology, such as advanced materials and heat transfer designs, contribute to increased energy efficiency and reduced drying times.

The Impact of Roll Technology Advancements

As roll technology continues to advance, the paper industry benefits from improved product quality, reduced downtime, and increased efficiency. Enhanced roll surface designs, materials, and coatings can significantly impact paper machine performance, offering advantages such as:

- Improved dewatering and drying capabilities

- Reduced energy consumption

- Increased machine speed and throughput

- Reduced maintenance requirements

- Enhanced paper quality and consistency

In conclusion, paper machine rolls are a critical component driving the paper industry forward. As technology advances and demand for high-quality, sustainable paper products grows, the importance of innovative roll design and materials will only continue to increase. By investing in advanced roll technology, paper manufacturers can ensure they remain competitive and meet the evolving needs of the market.