Understanding Paper Machine Rolls

Paper machine rolls are an essential component in paper manufacturing, responsible for guiding, supporting, and maintaining the web of paper during production. Choosing the right paper machine roll can significantly impact the efficiency, productivity, and quality of your paper production process.

Factors to Consider When Choosing a Paper Machine Roll

1. Roll Type: Different types of paper machine rolls serve various functions in the paper-making process. Common roll types include calendar rolls, guide rolls, drive rolls, and suction rolls. Understanding your production requirements will help you determine which type of roll is best for your needs.

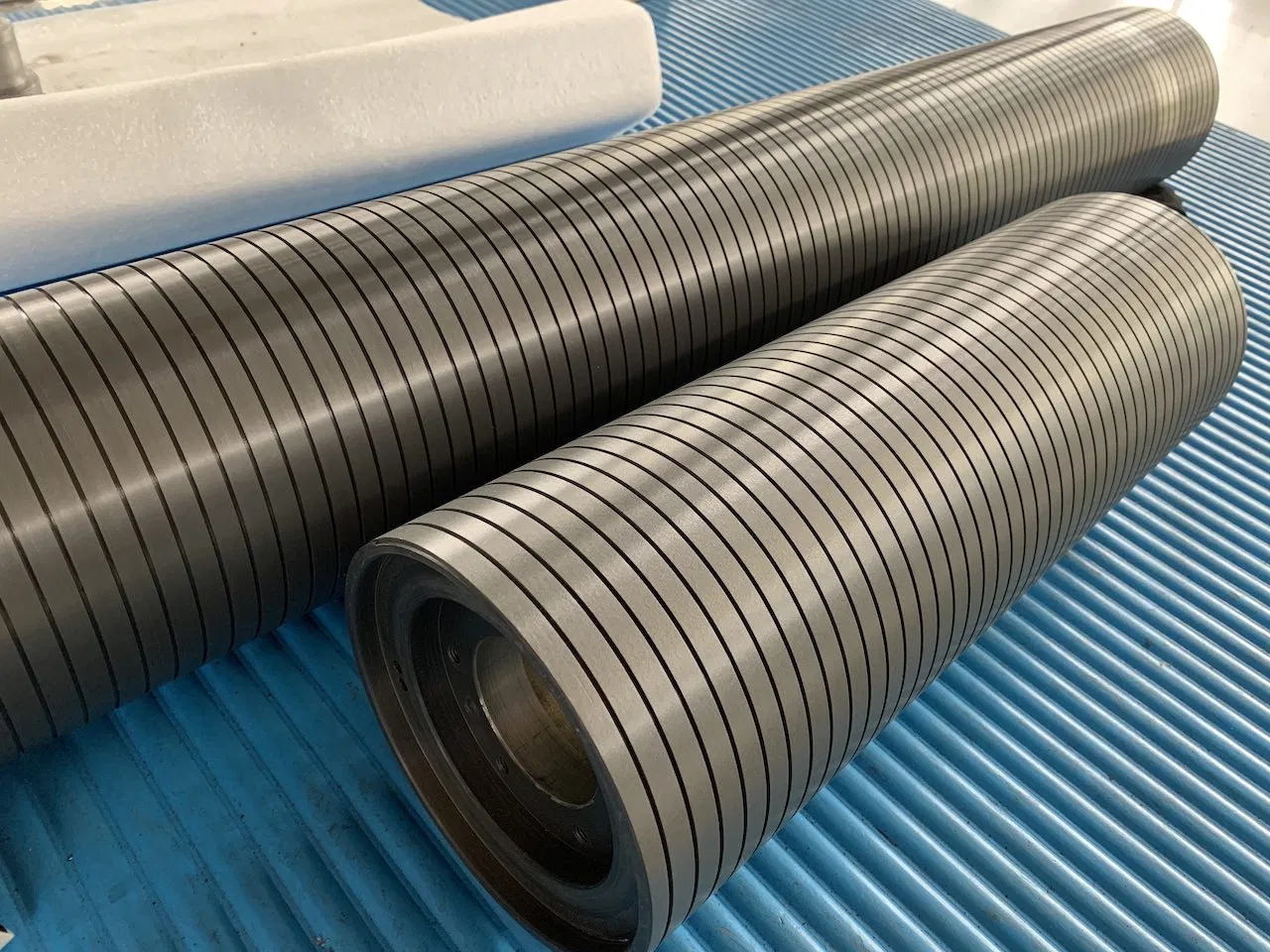

- Calendar Rolls: Smooth or patterned rolls used to impart finish or texture to the paper surface.

- Guide Rolls: Support rolls that help maintain paper web stability and alignment.

- Drive Rolls: Rolls responsible for moving the paper web through the machine.

- Suction Rolls: Rolls that remove water from the paper web using vacuum pressure.

2. Roll Material: Paper machine rolls are typically made from materials such as steel, cast iron, or composite materials. The choice of material depends on factors like roll application, temperature, and corrosion resistance requirements.

3. Roll Size and Dimensions: Proper roll size and dimensions are crucial for optimal performance and compatibility with your paper machine. Ensure that the roll's diameter, length, and journal size match your equipment specifications.

4. Roll Surface Quality: A high-quality roll surface is essential for maintaining consistent paper quality. Look for rolls with precise surface finishes, minimal surface defects, and appropriate hardness levels.

Tips for Selecting the Right Paper Machine Roll

1. Consult with an expert: Engage with a trusted paper machine roll supplier or manufacturer to discuss your specific needs and requirements. Their expertise can help guide you towards the best roll options.

2. Consider roll maintenance and repair: Investing in rolls that are easy to maintain and repair can save time and money in the long run. Opt for rolls with replaceable components or those that can be reground or recovered.

3. Evaluate roll performance: Request data or case studies demonstrating the roll's performance in similar applications. This information can help you make an informed decision about the roll's suitability for your paper production process.

Conclusion

Choosing the right paper machine roll is crucial for ensuring efficient and high-quality paper production. By considering factors such as roll type, material, size, and surface quality, and consulting with industry experts, you can make an informed decision that will ultimately benefit your paper manufacturing operations. Remember to also evaluate roll maintenance and performance to make the best choice for your specific needs.