The Importance of Rolls in Paper Mill Operations

Paper mills rely heavily on rolls to carry out various functions in the paper production process. These rolls are responsible for tasks such as guiding, supporting, and transferring paper sheets, as well as applying pressure and heat. Given the critical role that rolls play in paper mill operations, it is essential to ensure that they are of high quality and well-maintained.

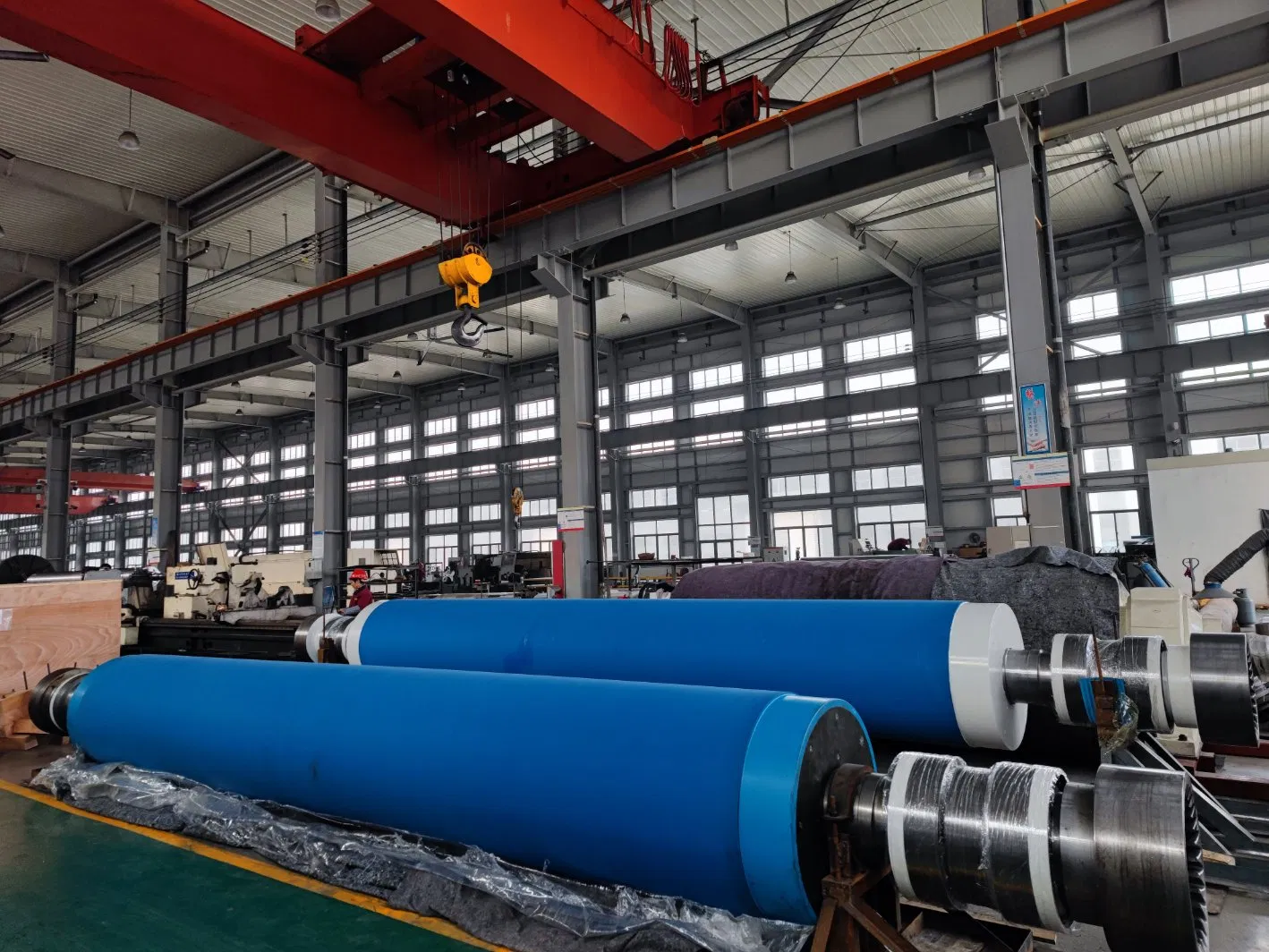

Benefits of Rubber Covered Rolls

Rubber covered rolls are a popular choice in paper mills due to the numerous benefits they offer. Here are some of the advantages of using rubber covered rolls in paper mill operations:

- Improved efficiency: Rubber covered rolls provide better grip and traction, allowing for more efficient paper transport and reduced sheet breakage.

- Reduced maintenance costs: Rubber covered rolls are more durable and resistant to wear and tear than other materials, resulting in lower maintenance costs and longer roll life.

- Enhanced roll performance: Rubber covered rolls offer better heat transfer, pressure distribution, and vibration dampening, leading to improved roll performance and paper quality.

Choosing the Right Rubber Covering for Your Rolls

When selecting rubber coverings for your rolls, there are several factors to consider, including the type of paper being produced, the operating conditions of the mill, and the specific requirements of the roll. Some common types of rubber coverings used in paper mills include:

- Nitrile rubber: Ideal for high-abrasion applications and resistance to oil, solvents, and chemicals.

- Neoprene rubber: Provides good abrasion resistance and flexibility, making it suitable for a wide range of paper mill operations.

- Silicone rubber: Offers excellent heat resistance and release properties, making it ideal for rolls used in high-temperature applications.

Maintaining Your Rubber Covered Rolls

To ensure the optimal performance and longevity of your rubber covered rolls, it is essential to carry out regular maintenance and inspections. This includes checking for signs of wear and tear, such as cracks, cuts, or abrasions, as well as measuring roll hardness and surface roughness. By taking a proactive approach to roll maintenance, you can minimize downtime, reduce costs, and improve overall productivity in your paper mill operations.