Introduction

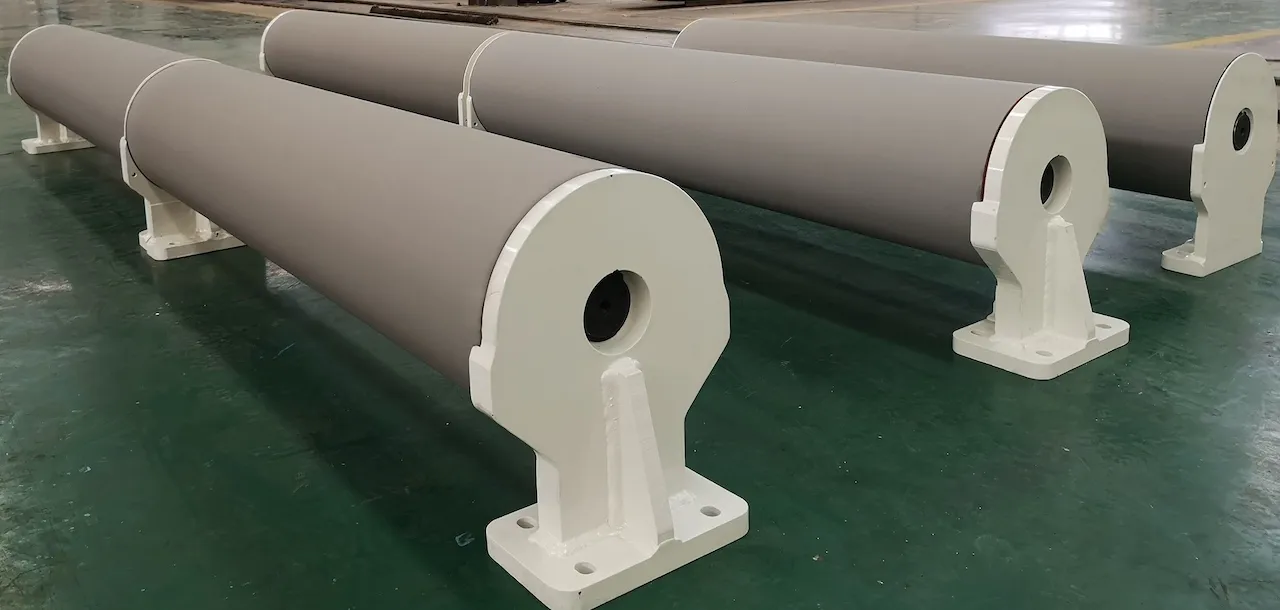

Paper machine roll coating solutions and applications have become increasingly popular in recent years. These solutions involve the application of a thin film coating to the surface of a paper machine roll, which enhances its performance and extends its lifespan. The coating can improve the roll's resistance to wear, corrosion, and heat, making it more durable and efficient in the production process.

Types of Paper Machine Roll Coating Solutions

There are several types of paper machine roll coating solutions available in the market, including:

- Chrome plating: This is the most common type of coating used in the paper industry. It provides excellent wear and corrosion resistance.

- Ceramic coating: This type of coating is used to improve the roll's heat resistance and reduce friction.

- Polymer coating: This type of coating is used to improve the roll's surface finish and enhance its release properties.

- Thermal spray coating: This type of coating is used to improve the roll's wear resistance and extend its lifespan.

Applications of Paper Machine Roll Coating Solutions

Paper machine roll coating solutions have a wide range of applications in the paper industry. Some of the most common applications include:

- Coating of calendar rolls: Calendar rolls are used to smooth and gloss the surface of the paper. Coating these rolls with ceramic or polymer coatings can improve their performance and reduce downtime.

- Coating of suction rolls: Suction rolls are used to remove water from the paper web. Coating these rolls with chrome or thermal spray coatings can improve their wear resistance and extend their lifespan.

- Coating of guide rolls: Guide rolls are used to guide the paper web through the machine. Coating these rolls with polymer or thermal spray coatings can improve their surface finish and reduce friction.

- Coating of doctor rolls: Doctor rolls are used to remove excess coating from the paper web. Coating these rolls with chrome or polymer coatings can improve their wear resistance and reduce downtime.

Benefits of Paper Machine Roll Coating Solutions

Paper machine roll coating solutions offer several benefits to paper manufacturers, including:

- Improved roll performance: Coated rolls perform better than uncoated rolls, resulting in higher productivity and lower downtime.

- Reduced maintenance costs: Coated rolls have a longer lifespan than uncoated rolls, reducing the need for frequent replacement and maintenance.

- Improved product quality: Coated rolls provide a smoother and more consistent surface finish, resulting in higher product quality.

- Reduced environmental impact: Coated rolls require less energy and water to operate, reducing their environmental impact.

Conclusion

Paper machine roll coating solutions and applications have become essential in the paper industry. They offer numerous benefits, including improved roll performance, reduced maintenance costs, improved product quality, and reduced environmental impact. By understanding the different types of coatings and their applications, paper manufacturers can make informed decisions and choose the right solutions for their needs.