Roller Functions in Paper Machines

Paper machine rollers are essential components in the paper production process, playing a critical role in sheet formation, dewatering, and drying. The primary functions of paper machine rollers include guiding, supporting, and applying pressure to the paper web as it travels through the machine.

Sheet Formation and Dewatering

As the paper stock is dispersed onto a moving wire mesh, rollers help in forming a uniform sheet by removing water and consolidating the fibers. Suction rollers, for instance, are designed to draw water from the paper web, promoting better fiber bonding and enhancing paper stability.

Different Types of Paper Machine Rollers

Various types of rollers are employed in paper machines to perform specific tasks. Here are some of the most commonly used rollers:

Press Rollers

- These rollers apply pressure to the paper web to remove excess water and improve fiber bonding.

Dryer Rollers

- Dryer rollers use steam to evaporate the remaining water in the paper web.

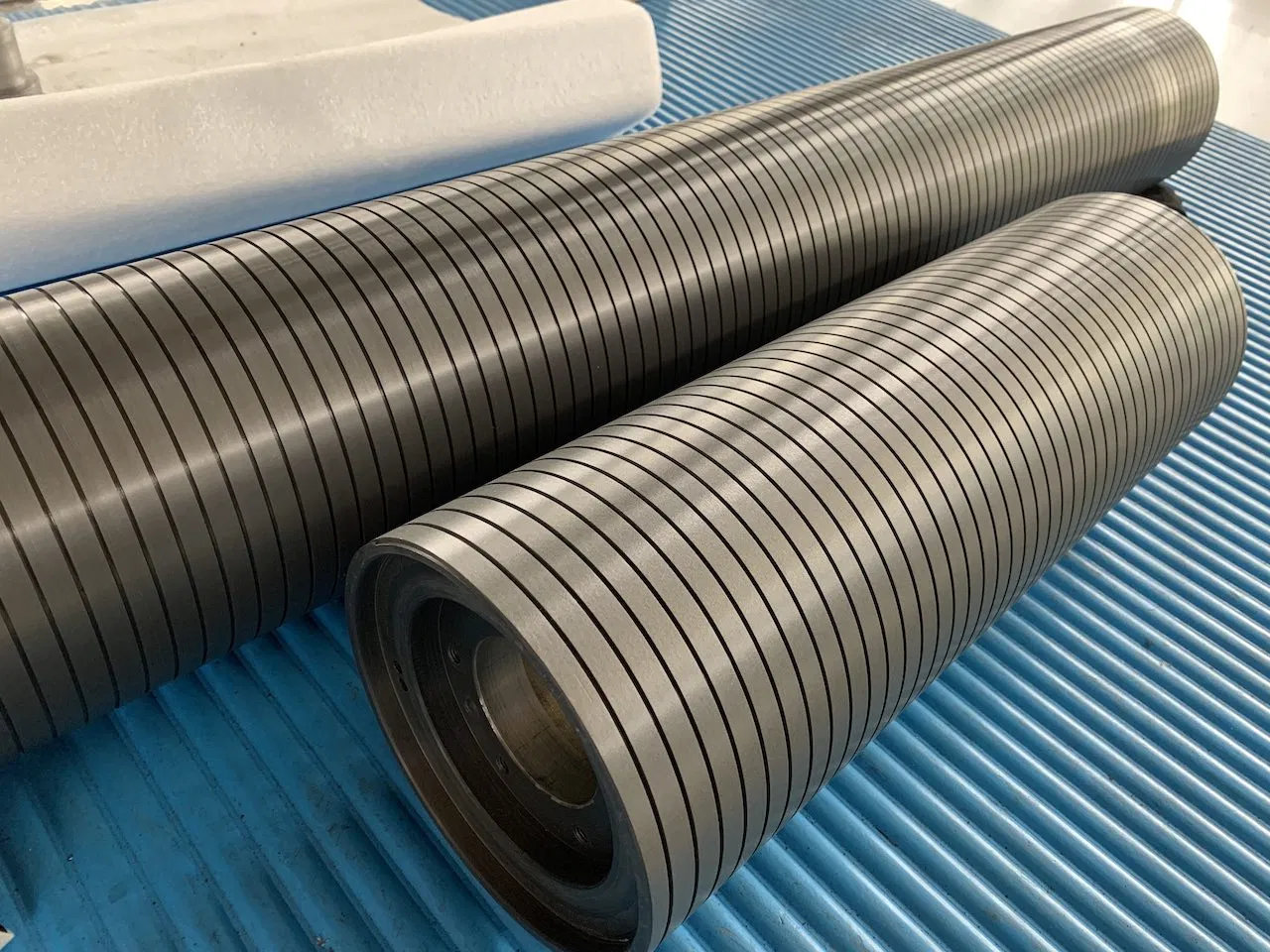

Calender Rollers

- Calender rollers are responsible for the paper's final finish, smoothness, and gloss.

Guide Rollers

- These rollers ensure the paper web stays aligned and moves smoothly through the machine.

Maintaining Paper Machine Rollers

Proper maintenance of paper machine rollers is crucial to ensure optimal performance and minimize downtime. Regular inspections and preventive maintenance can help identify potential issues before they become critical. Some essential maintenance activities include:

Cleaning and Lubrication

- Regular cleaning and lubrication of rollers prevent the buildup of contaminants, reduce wear, and prolong roller life.

Roller Cover Replacement

- Replacing roller covers when they become worn or damaged ensures consistent paper quality and prevents costly repairs.

Alignment and Balancing

- Ensuring proper alignment and balance of rollers reduces vibration, improves paper quality, and minimizes energy consumption.

Regular Inspections

- Conducting routine visual inspections helps to identify any signs of wear, damage, or misalignment, allowing for timely repairs and adjustments.

By understanding the functions, types, and maintenance requirements of paper machine rollers, operators can ensure optimal performance and minimize downtime in their paper production processes.