Introduction to Rollers for the Paper Industry

The paper industry relies heavily on rollers to produce high-quality products. These rollers play a crucial role in various stages of the papermaking process, from sheet formation to drying and finishing. In this article, we will explore the different types of rollers used in the paper industry, their applications, and maintenance tips to ensure optimal performance.

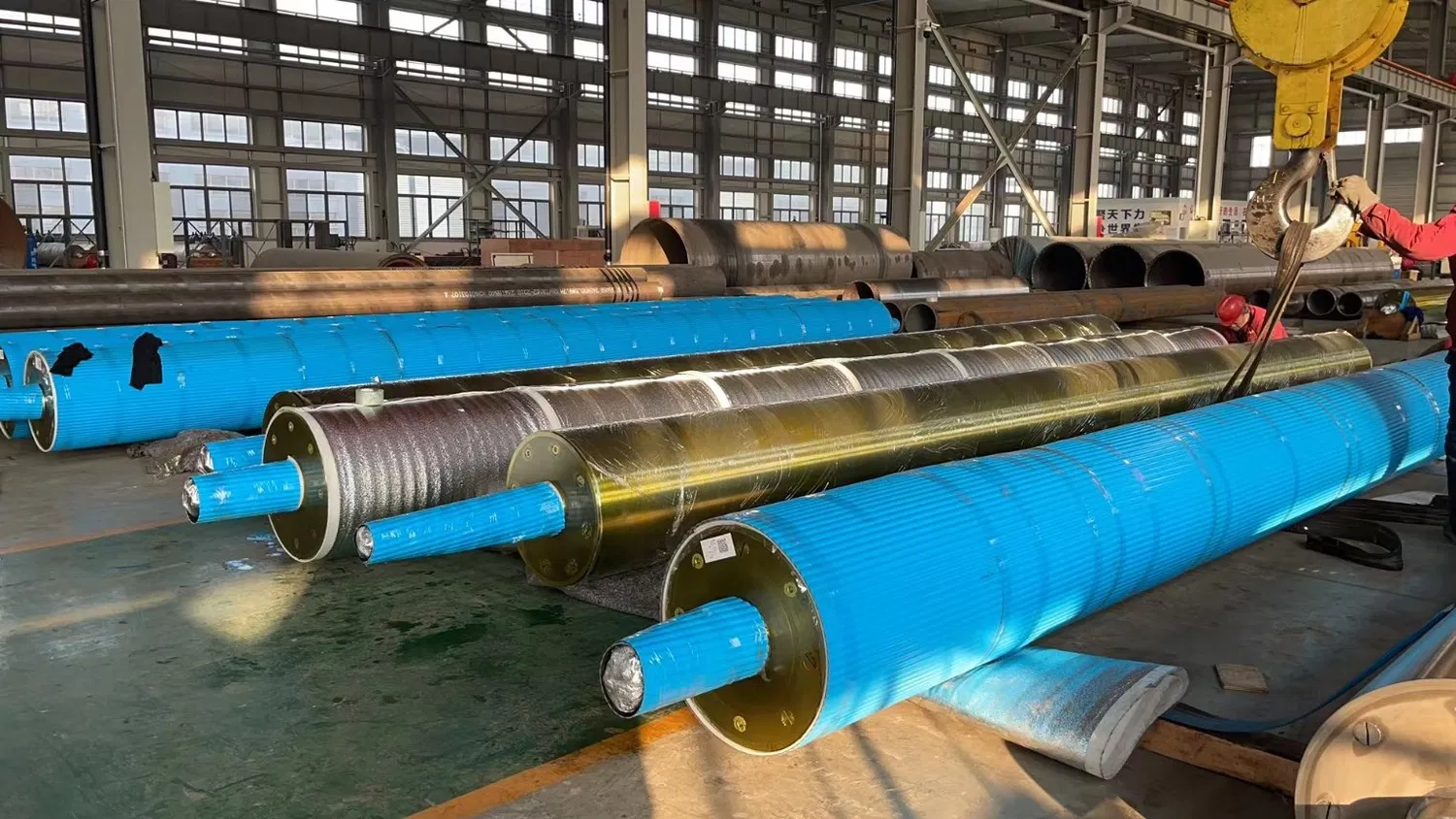

Types of Rollers for the Paper Industry

There are several types of rollers used in the paper industry, each with its unique function. The most common types include:

1. Suction Rollers: These rollers use vacuum pressure to pick up the wet paper sheet from the wire section and transfer it to the press section.

2. Press Rollers: These rollers apply pressure to remove excess water from the paper sheet, improving its density and strength.

3. Dryer Rollers: These rollers use heat and pressure to dry the paper sheet, preparing it for finishing.

4. Calendar Rollers: These rollers apply pressure to the paper sheet to smooth out its surface and improve its gloss.

Applications of Rollers in the Paper Industry

Rollers are used in various stages of the papermaking process, each with its unique application. Here are some of the most common applications:

1. Sheet Formation: Suction rollers are used to pick up the wet paper sheet from the wire section and transfer it to the press section.

2. Pressing: Press rollers are used to apply pressure to the paper sheet, removing excess water and improving its density and strength.

3. Drying: Dryer rollers use heat and pressure to dry the paper sheet, preparing it for finishing.

4. Finishing: Calendar rollers apply pressure to the paper sheet to smooth out its surface and improve its gloss.

Maintenance Tips for Rollers in the Paper Industry

Proper maintenance of rollers is essential to ensure optimal performance and extend their lifespan. Here are some maintenance tips:

1. Regular Cleaning: Regular cleaning of rollers is necessary to remove dirt, dust, and debris that can accumulate on their surfaces.

2. Lubrication: Proper lubrication of rollers is essential to reduce friction and prevent wear and tear.

3. Inspection: Regular inspection of rollers can help identify any issues early on, preventing costly repairs or replacements.

4. Replacement: When rollers are beyond repair, it is necessary to replace them to ensure optimal performance.

Conclusion

Rollers are an essential component in the paper industry, playing a crucial role in various stages of the papermaking process. By understanding the different types of rollers, their applications, and maintenance tips, paper manufacturers can ensure optimal performance and extend the lifespan of their equipment. Whether you are a seasoned professional or new to the industry, this comprehensive guide to rollers for the paper industry will provide valuable insights and practical tips for success.